Fresh cassava soaking and washing method

A technology of fresh cassava and cassava, applied in the fields of application, food processing, climate change adaptation, etc., can solve problems such as not considering process water recycling, weak awareness of water resource recycling, waste of clean water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

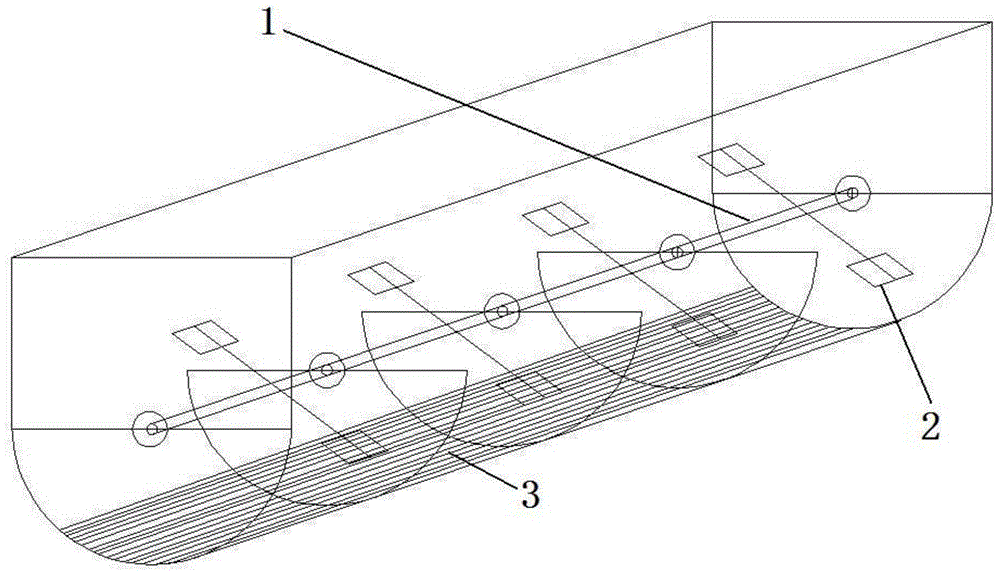

[0012] The production of the potato bath pool - the potato bath pool has an arc-shaped bottom, and four grid pools are arranged in sequence along the central axis of the potato bath pool. The grid pool is composed of a grid and a pool under it. Four-stage soaking of cassava; each grid is about 90cm long and 70cm wide, and is welded by stainless steel bars according to a certain gap; a certain number of stirring paddles 2 are installed on the grid pool 3 along the central axis 1 of the potato bath pool .

[0013] Four-stage soaking - the deslimed and peeled cassava is sent to the potato bath pool for four-stage soaking through the primary conveyor belt. When soaking cassava, put the cassava in the first grid pool of the potato bath pool , the water in the grid pool has not covered the cassava so that it can be fully soaked and washed, and the cassava is soaked in the potato bath pool while being stirred by the stirring paddle, and is transferred from the first grid pool to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com