Atmosphere passing cover type mobile trolley furnace

A trolley furnace and atmosphere technology, applied in furnaces, furnace types, furnace components, etc., can solve the problems of inconvenient operation of quenching and annealing, poor sealing effect of sealing mechanism, and increase the scrap rate of workpieces, so as to reduce the scrap rate, The effect of good sealing performance and low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the drawings and embodiments.

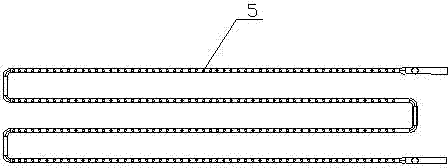

[0026] Atmosphere hood mobile trolley furnace, including furnace body 1, furnace door 2, trolley 3, trolley running mechanism 9 located at the bottom of said furnace body 1, and furnace door lifting gantry 7. The electric heating element 10 and the electrical control system. The furnace body 1 is formed by welding a rectangular shaped furnace shell skeleton, steel plate and furnace lining 8 by sealing and welding. The acid aluminum refractory fiber construction also includes an atmosphere inlet device and a furnace body guiding and sealing mechanism. The atmosphere inlet device includes a gas generator 12, an inlet pipe 11, and a steel pipe 4 made into a circular shape. The gas generator 12 passes The inlet pipe 12 is fixedly connected with the steel pipe 4, a gas generator 12 is connected to two inlet pipes 12, and each inlet pipe 12 is fixedly connected with the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com