Preparation method of mooring rope for anchoring aircraft carrier

A technology for cables and aircraft carriers, applied in the field of ropes, can solve the problems of high rigidity, inconvenient operation, heavy weight of ordinary steel bars, etc., and achieve the effects of light weight, low shrinkage rate and stable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

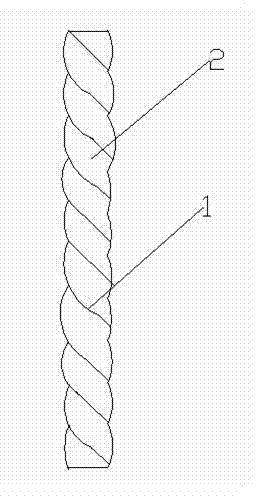

[0014] The preparation method for the anchoring cable of the aircraft carrier is realized through the following steps:

[0015] 1) Material selection: Ultra-high molecular weight polyethylene fiber filaments are selected, and their specifications are 1000D-3000D;

[0016] 2) Doubling: 50-1000 ultra-high molecular weight polyethylene fiber filaments are used for doubling and 1 strand;

[0017] 3) Twisting: After paralleling, the ultra-high molecular weight polyethylene fiber filaments are twisted through a twisting machine, and the transmission belt of the twisting machine is tight and tight. Each filament must be controlled by a tension regulator, and its speed and twist are measured regularly , the twist is less than 20 twists / m;

[0018] 4) Heat setting: The twisted ultra-high molecular weight polyethylene fiber filaments are heat-set for 30-80 minutes at a temperature of 60-80°C and a pressure of 0.05-0.08Mpa through a steam setting machine to obtain ultra-high molecular w...

Embodiment 1

[0021] 1) Material selection: The selected raw material is ultra-high molecular weight polyethylene fiber filament, and its specification is 1000D;

[0022] 2) Doubling: 50 ultra-high molecular weight polyethylene fiber filaments are used for doubling and 1 strand;

[0023] 3) Twisting: After paralleling, the ultra-high molecular weight polyethylene fiber filaments are twisted through a twisting machine, and the transmission belt of the twisting machine is tight and tight. Each filament must be controlled by a tension regulator, and its speed and twist are measured regularly , the twist depends on the size of the strands, generally less than 20 twists / m;

[0024] 4) Heat setting: heat setting the twisted ultra-high molecular weight polyethylene fiber filaments through a steam setting machine at a temperature of 60°C and a pressure of 0.05Mpa for 30 minutes to obtain a strand 1;

[0025] 5) Forming: 500 heat-set ultra-high molecular weight polyethylene fiber strands 1 are twis...

Embodiment 2

[0027] 1) Material selection: The selected raw material is ultra-high molecular weight polyethylene fiber filament, and its specification is 1260D;

[0028] 2) Doubling: 1000 ultra-high molecular weight polyethylene fiber filaments are used for doubling and 1 strand;

[0029] 3) Twisting: After paralleling, the ultra-high molecular weight polyethylene fiber filaments are twisted through a twisting machine, and the transmission belt of the twisting machine is tight and tight. Each filament must be controlled by a tension regulator, and its speed and twist are measured regularly , the twist depends on the size of the strands, generally less than 20 twists / m;

[0030] 4) Heat setting: heat setting the twisted ultra-high molecular weight polyethylene fiber filaments through a steam setting machine at a temperature of 70°C and a pressure of 0.07Mpa for 50 minutes to obtain a strand 1;

[0031] 5) Forming: 50 heat-set ultra-high molecular weight polyethylene fiber strands 1 are twi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com