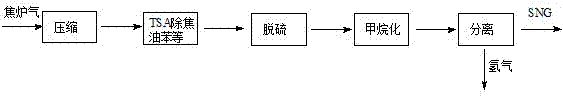

New technology for preparing natural gas through coke-oven gas methanation

A technology of natural gas and gas methane, applied in the application field of coke oven gas, can solve the problem of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

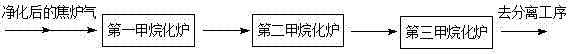

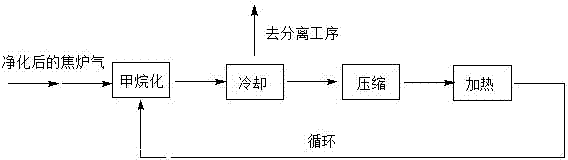

[0026] In this example, the method for producing substitute natural gas by methanation of coke oven gas is as follows, and the flow chart is shown in Figure 4 :

[0027] After the coke oven gas is desulfurized, the composition (vol%) of the obtained mixed gas is: H 2 56.14, CH 4 31.28, CO 6.87, CO 2 2.08,N 2 1.20, C 2 h 6 2.43, the total sulfur content is less than 0.1ppm, and under the action of the nickel catalyst system with alumina as the carrier, the first-stage methanation reaction is carried out to obtain a mixed gas with a methane content of about 55%. The pressure of the first-stage methanation reactor is about is 2.0MPa, the reactor inlet temperature is about 250°C; the gas composition (vol%) at the outlet of the first-stage methanation reaction is: H 2 39.12, CH 4 55.20, CO 1.23, CO 2 1.37,N 2 1.10, C 2 h 6 1.98.

[0028] CO compensation at the inlet of the second-stage methanation reactor 2 , the inlet gas composition (vol%) of the second-st...

Embodiment 2

[0031] In this example, the method for producing substitute natural gas by methanation of coke oven gas is as follows, and the flow chart is shown in Figure 4 :

[0032] After the coke oven gas is desulfurized, the composition (vol%) of the obtained mixed gas is: H 2 56.14, CH 4 31.28, CO 6.87, CO 2 2.08,N 2 1.20, C 2 h 6 2.43, the total sulfur content is less than 0.1ppm, and under the action of the nickel catalyst system with alumina as the carrier, the first-stage methanation reaction is carried out to obtain a mixed gas with a methane content of about 55%. The pressure of the first-stage methanation reactor is about is 5.0MPa, and the reactor inlet temperature is about 350°C; the gas composition (vol%) at the outlet of the first-stage methanation reaction is: H 2 39.22, CH 4 53.20, CO 1.20, CO 2 1.32,N 2 1.15, C 2 h 6 2.91.

[0033] CO compensation at the inlet of the second-stage methanation reactor 2, the inlet gas composition (vol%) of the second...

Embodiment 3

[0036] In this example, the method for producing substitute natural gas by methanation of coke oven gas is as follows, and the flow chart is shown in Figure 4 :

[0037] After the coke oven gas is desulfurized, the composition (vol%) of the obtained mixed gas is: H 2 56.14, CH 4 31.28, CO 6.87, CO 2 2.08,N 2 1.20, C 2 h 6 2.43, the total sulfur content is less than 0.1ppm, under the action of the nickel catalyst system supported by alumina and magnesium aluminum spinel, the first-stage methanation reaction is carried out to obtain a mixed gas with a methane content of about 55%. The first-stage methane The pressure of the methanation reactor is about 2.0MPa, and the reactor inlet temperature is about 250°C; the gas composition (vol%) at the outlet of the first-stage methanation reaction is: H 2 39.12, CH 4 55.20, CO 1.23, CO 2 1.37,N 2 1.10, C 2 h 6 1.98.

[0038] Compensation C at the inlet of the second-stage methanation reactor 2 h 6 , the inlet gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com