Liquid vinyl chloride monomer dehydration system and dehydration process thereof

A vinyl chloride monomer, liquid phase technology, applied in liquid separation, immiscible liquid separation, separation methods, etc., can solve the problems of equipment cleaning difficulty, coalescing filter block clogging, increase residence time and other problems, to ensure long-term normal operation , The effect of reducing the size of the equipment and shortening the settling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

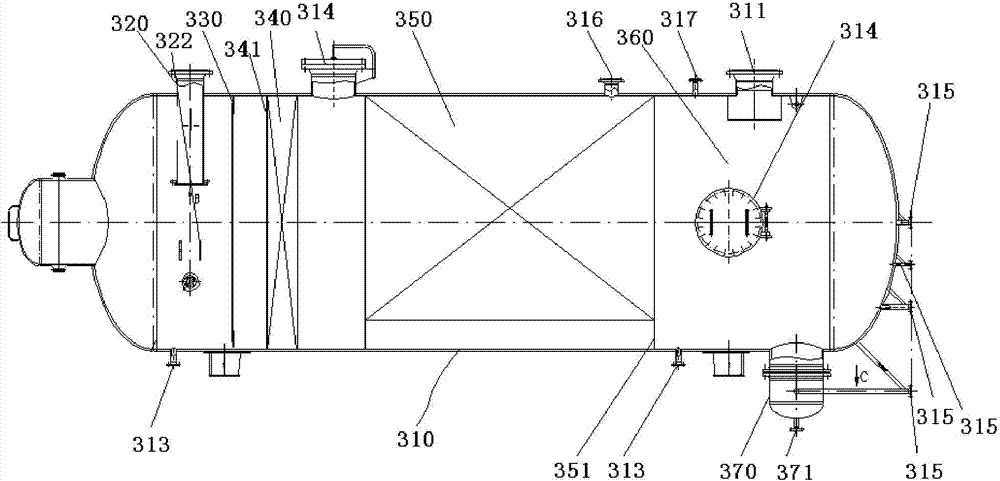

[0039] see figure 1 and figure 2As shown, the present invention discloses a liquid-phase vinyl chloride monomer dehydration system, including a phase separator 300 and an interface automatic control system 400 connected to the phase separator 300; The material inlet end 320 on one end of 310, the inlet piece 322 connected to the material inlet end 320, the rectifier 330 connected to the inlet piece 322, the fiber filler section 340 arranged behind the rectifier 330, the fiber filler section 340 arranged behind The baffle section 350, the settling section 360 arranged behind the baffle section 350, the small cylinder 370 arranged on the outer surface of the bottom of the cylinder 310, and the light phase outlet 311 arranged on the top of the cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com