Novel vacuum evaporator

A new type of vacuum evaporation technology, applied in the field of new vacuum evaporators, can solve the problems of scaling, easy scaling of waste water, corrosion of condensation tanks, etc., and achieve the effects of prolonging life, simple and convenient operation, and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

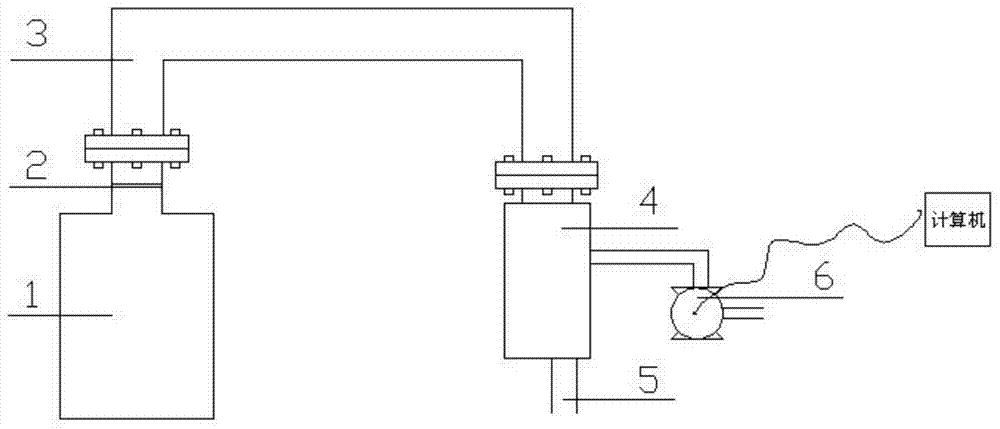

[0016] The evaporator 1 and the cover 3 are fixedly connected by a flange, and the polytetrafluoroethylene sealing ring is located at the flange connection between the evaporator 1 and the cover 3, and the evaporator 1 and the cover 3 are connected. The gasket makes the evaporator The sealing effect is better, and it also makes the whole process cleaner and safer, which effectively improves the work efficiency. The demister 2 is located under the upper flange of the evaporation tank, and is fixed on the evaporation tank by welding. The demister is in the shape of Disc-shaped, the steam can remove the entrained liquid foam through the demister, and only allow the gas to enter the cover 3 through the demister to enter the condenser, preventing the evaporating liquid from entering the condenser to cause fouling and corrosion of the condenser, maintaining the The cleanliness and safety of the equipment effectively protect the cover 3 and the condensation tank 4, prolonging the life...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com