Pellet composition containing diclofenac sodium and preparation method thereof

A technology of diclofenac sodium and its composition, which is applied in the field of capsules containing diclofenac sodium micropills composition and its preparation, can solve the problems of high price, narrow selection, and increased economic burden on patients, and achieve high roundness and low Stable and uniform effect of stimulation and release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]

[0034] Preparation of pellet core: Mix the prescribed amount of diclofenac sodium, microcrystalline cellulose and micropowder silica gel through a 60-mesh sieve, pour the mixed powder into a high-shear granulator and mix for 3 minutes, then set the speed of the stirring paddle 5rpm, cutting knife rotation speed 15rpm, add 3% povidone to prepare soft material. Put the soft material into the extrusion spheronizer, set the extrusion temperature to 8°C, the extrusion speed to 40rpm, and the spheronization speed to 1500rpm to prepare pellet cores. The obtained pellet cores were dried in an oven at 60°C, and when the water content was lower than 3%, they were sieved with a 24-mesh to 40-mesh sieve to obtain medium-sized pellets.

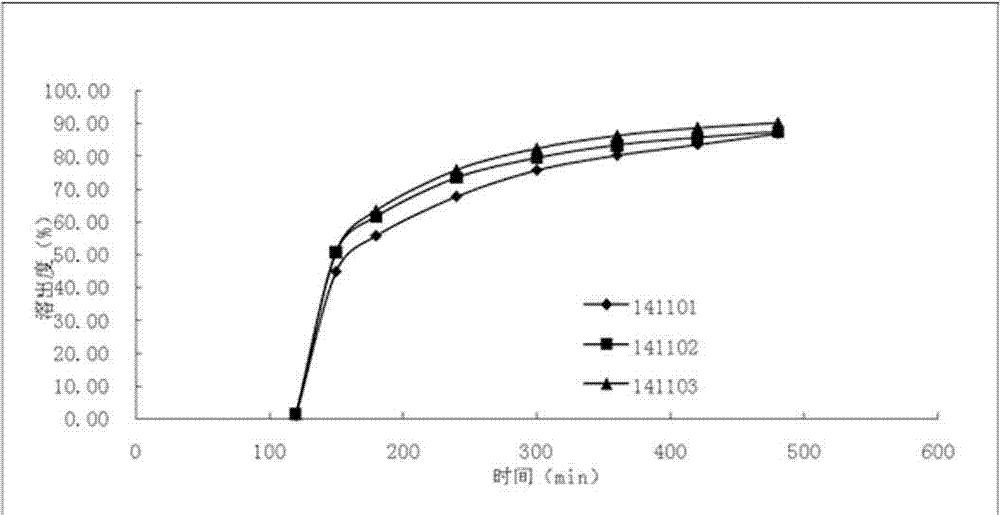

[0035] Preparation of enteric-coated pellets: Formulate the prescribed amount of enteric-coated material into a coating solution, use 60% ethanol to prepare, set the fluidized bed inlet air temperature to 55°C, spray pressure to 1.8bar, materi...

Embodiment 2

[0039]

[0040] Preparation of pellet core: Mix the prescribed amount of diclofenac sodium, microcrystalline cellulose and micropowder silica gel through a 60-mesh sieve, pour the mixed powder into a high-shear granulator and mix for 3 minutes, then set the speed of the stirring paddle 5rpm, the cutter speed is 15rpm, and 5% povidone is added to prepare the soft material. Put the soft material into the extrusion spheronizer, set the extrusion temperature to 8°C, the extrusion speed to 40rpm, and the spheronization speed to 1000rpm to prepare pellet cores. The obtained pellet cores were dried in an oven at 60°C, and when the water content was lower than 3%, they were sieved with a 24-mesh to 40-mesh sieve to obtain medium-sized pellets.

[0041] Preparation of enteric-coated pellets: Formulate the prescribed amount of enteric-coated material into a coating solution, use 95% ethanol to prepare, set the fluidized bed inlet air temperature to 35°C, spray pressure to 1.8bar, ma...

Embodiment 3

[0045]

[0046] Preparation of pellet core: Mix the prescribed amount of diclofenac sodium, microcrystalline cellulose 101, croscarmellose sodium and micropowder silica gel through an 80-mesh sieve, pour the mixed powder into a high-shear granulator and mix After mixing for 5 minutes, set the rotation speed of the stirring blade to 5 rpm, the rotation speed of the cutting knife to 25 rpm, and add 5% povidone to prepare a soft material. Put the soft material into the extrusion spheronizer, set the extrusion temperature to 8°C, the extrusion speed to 40rpm, and the spheronization speed to 1000rpm to prepare pellet cores. The obtained pellet cores were dried in an oven at 60°C, and when the water content was lower than 3%, they were sieved with a 24-mesh to 40-mesh sieve to obtain medium-sized pellets.

[0047] Preparation of enteric-coated pellets: Formulate the prescribed amount of enteric-coated material into a coating solution, use 95% ethanol to prepare, set the fluidize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com