Method for producing an LED module and LED module

A technology for LED modules and housings, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as enhanced strong reflection, color fluctuations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

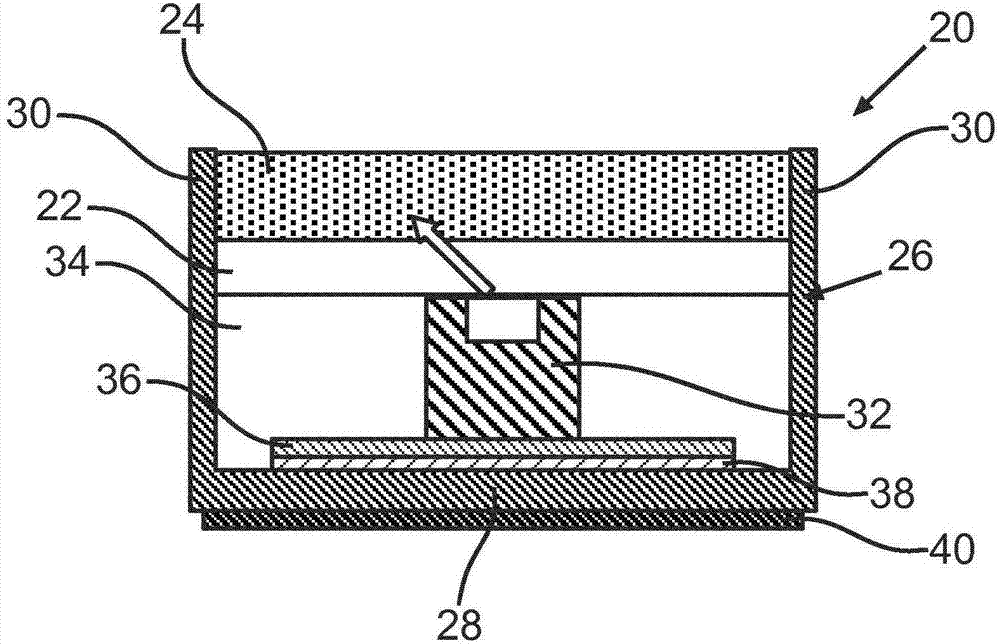

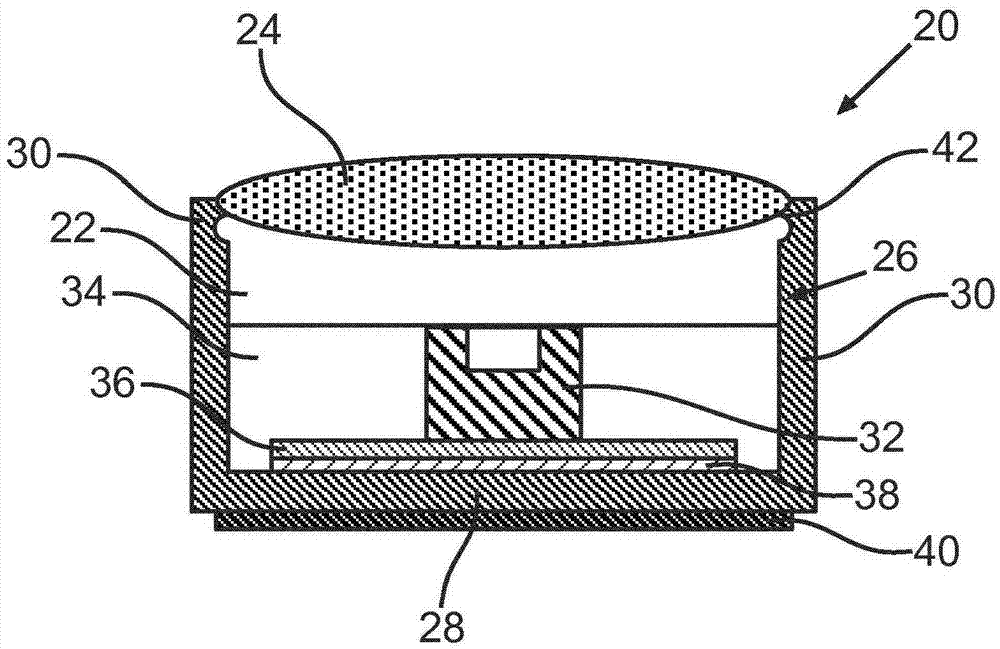

[0042] figure 2 A schematic diagram of an LED module 20 with a first base layer 22 and a scattering layer 24 of transparent design according to one embodiment of the invention is shown. The LED module 20 here comprises a housing 26 with a base side 28 and a boundary side 30 which delimits the LED module 20 to the outside. Depending on the design of the housing 26 , the boundary side 30 can include several regions, for example a front region, a rear region, and two lateral regions. The housing 26 can, for example, also be circular, rotationally symmetrical or groove-shaped. Preference is given here to an embodiment of the housing 26 which, as shown, has a U-shaped profile in cross section and extends in the direction of longitudinal extension perpendicular to the plane of the cross section shown. In the direction of longitudinal extension, a plurality of LEDs 32 are arranged linearly, in particular on a circuit board 36 which is arranged on the base side 28 of the housing 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com