Composite solar battery photovoltaic solder strip

A technology for solar cells and photovoltaic ribbons, applied in the fields of photovoltaic power generation, circuits, electrical components, etc., can solve the problems of reduced flexibility of the ribbons, damage to the battery cells, etc., to release thermal stress and mechanical stress, reduce dosage, and improve surface adaptation. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

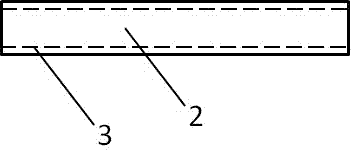

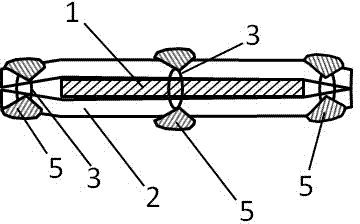

[0022] see Figure 1 to Figure 4 As shown, the composite solar cell photovoltaic welding ribbon of the present invention includes a longitudinally extending strip body, the strip body includes a conductive thread 1, a copper strip 2 and a sewing thread 3, the copper strip 2 is stitched by the sewing thread 3, and the copper foil strip surrounds the conductive Line 1. The conductive wire 1 is composed of conductive filaments arranged in parallel or twisted. The thickness of the copper strip 2 is 20 microns to 350 microns.

[0023] figure 1 and figure 2 The strip body shown in Example 1 includes a tin-coated layer 4 coated on the surface of the copper strip 2 . The cross-sectional direction of the belt body is sewn by sewing thread 3, along the axial direction of the belt bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com