Method for rapidly fixing micro-quake sensor underground

A microseismic sensor and sensor technology, applied in seismic signal transmission, seismic signal receiver, seismology for well logging, etc., can solve the problems of poor isolation of noise, cumbersome installation process, economic loss, etc. Achieve fast installation and removal, reduce the consumption of manpower and material resources, and save the amount of engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

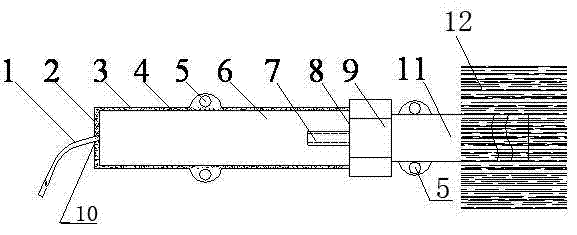

[0036] The present invention will be further described below in conjunction with the accompanying drawings: a method for quickly fixing a microseismic sensor downhole, characterized in that: through a device for quickly fixing a microseismic sensor downhole, referred to as the device, the microseismic sensor 6 and the anchor embedded in the rock mass The rod 11 is tightly connected to fix the microseismic sensor 6 at a predetermined monitoring position. The rock mass microseismic signal is transmitted to the microseismic sensor 6 through the anchor rod 11 and the device, and the microseismic sensor 6 connects the signal to the external computer system through the cable 1.

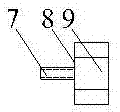

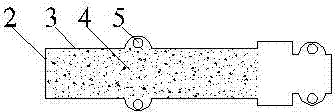

[0037] A device for quickly fixing a microseismic sensor in a well is composed of two parts: an outer cover and a connector. The outer cover is composed of a bottom plate 2, a cover body 3, an external sound wave insulating material 4 and a closed hole 5; It is composed of a fixed bolt 9; the protruding shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com