Hot forging pressing process water meter copper shell and manufacturing method thereof

A manufacturing method and hot forging technology are applied in the hot forging process water meter copper shell and its manufacturing field, which can solve the problems of fracture, easy generation of small pores in the shell wall, insufficient shell strength, etc. Smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

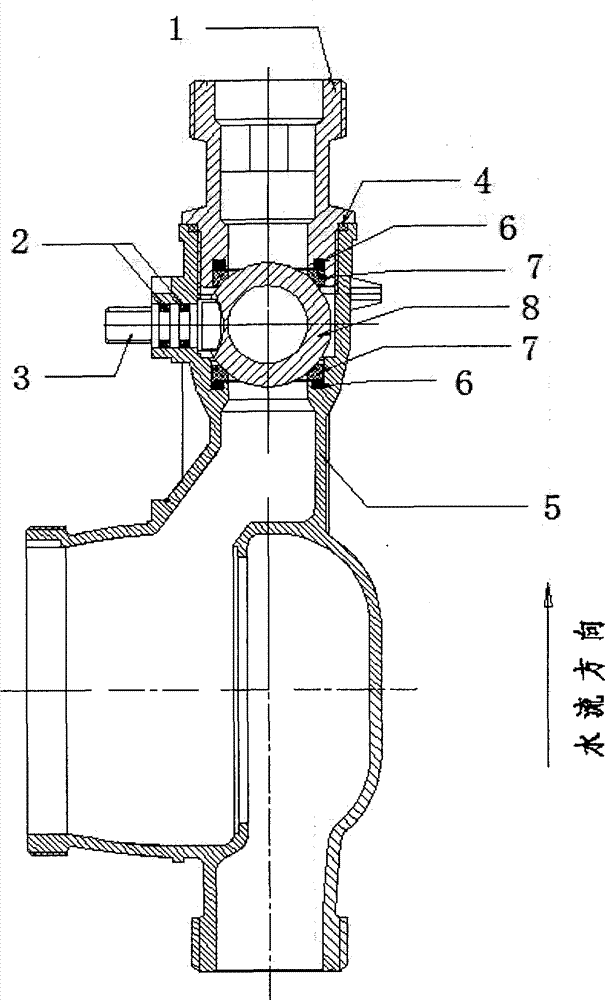

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0029] The hot forging process water meter copper shell of the present invention comprises a hot forging process water meter copper shell and a manufacturing method thereof, comprising the following steps:

[0030] S1: Cutting copper rods with a diameter of φ60 to 75MM and a weight of 1600 to 1900 grams;

[0031] S2: Rapidly heat the copper rod that has passed through S1 to between 700 and 800 degrees through the heating furnace equipment;

[0032] S3: Put the copper bar material obtained in S2 into the stamping equipment and the special water meter copper shell mold for hot forging and stamping;

[0033] S4: trimming the copper shell blank that has passed through S3;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com