Main girder structure system of double-layer bridge deck cable-stayed bridge

A cable-stayed bridge and main girder technology, applied in bridges, bridge forms, truss bridges, etc., can solve the problems of high steel consumption of superimposed truss girder, increased scale of main bridge, and low self-weight concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

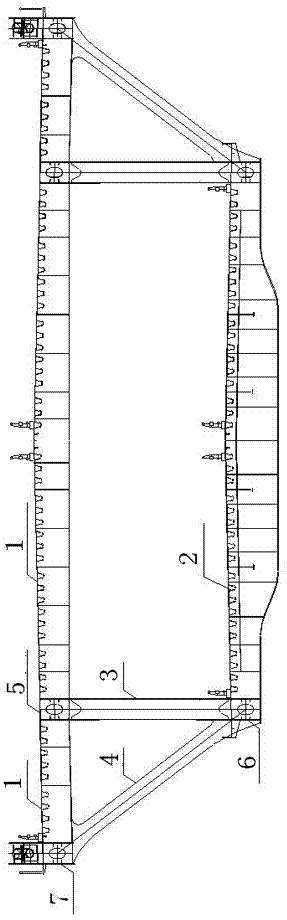

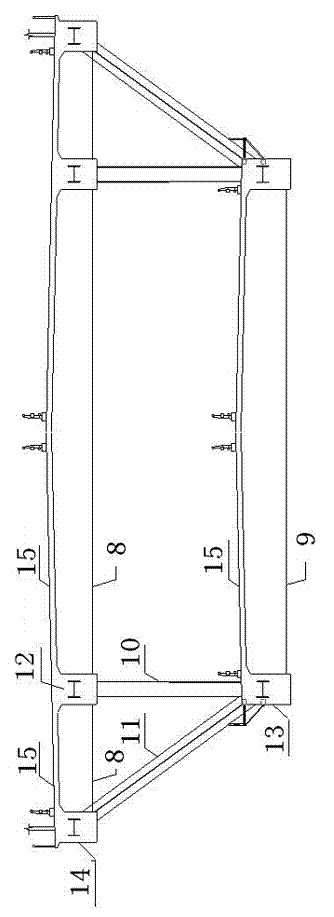

[0010] Attached below Figure 1~3 And embodiment the present invention is described further.

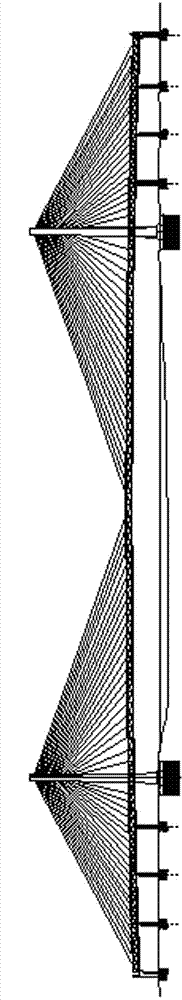

[0011] A bridge is a double-deck road cable-stayed bridge with a main span of 708 meters. The main girder adopts a plate-truss combined steel truss girder with a side span of 4×63 meters. The main girder adopts a composite truss structure system. (see attached Figure 1~3 ).

[0012] The mid-span main girder is composed of steel trusses and orthotropic steel deck systems. The chords of the steel trusses are completely welded to the steel bridge deck; the side-span main girders are composed of concrete-coated steel chords, steel webs, prestressed concrete beams, Concrete deck composition (see attached image 3 ).

[0013] as attached figure 2 As shown, the mid-span main girder of the double-deck road cable-stayed bridge includes an upper orthotropic steel deck system 1, a lower orthotropic steel deck system 2, a steel truss web member 3 and a steel truss diagonal member 4 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com