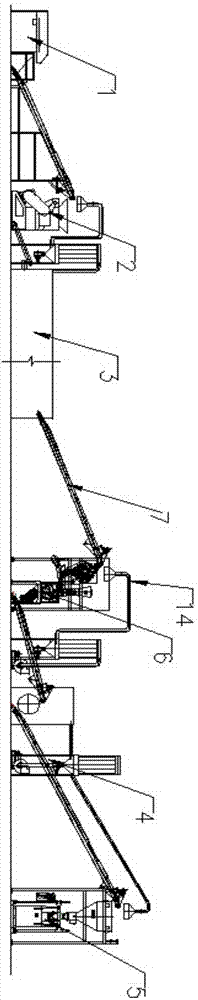

Process and production line for processing natural asphalt by virtue of aid method

A technology of natural asphalt and processing technology, which is applied in the processing of tar asphalt/petroleum asphalt/natural asphalt, processing tar asphalt/petroleum asphalt/natural asphalt by heating, curing/crushing processing tar asphalt/petroleum asphalt/natural asphalt, etc. It can solve problems such as unenvironmental protection, high cost and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

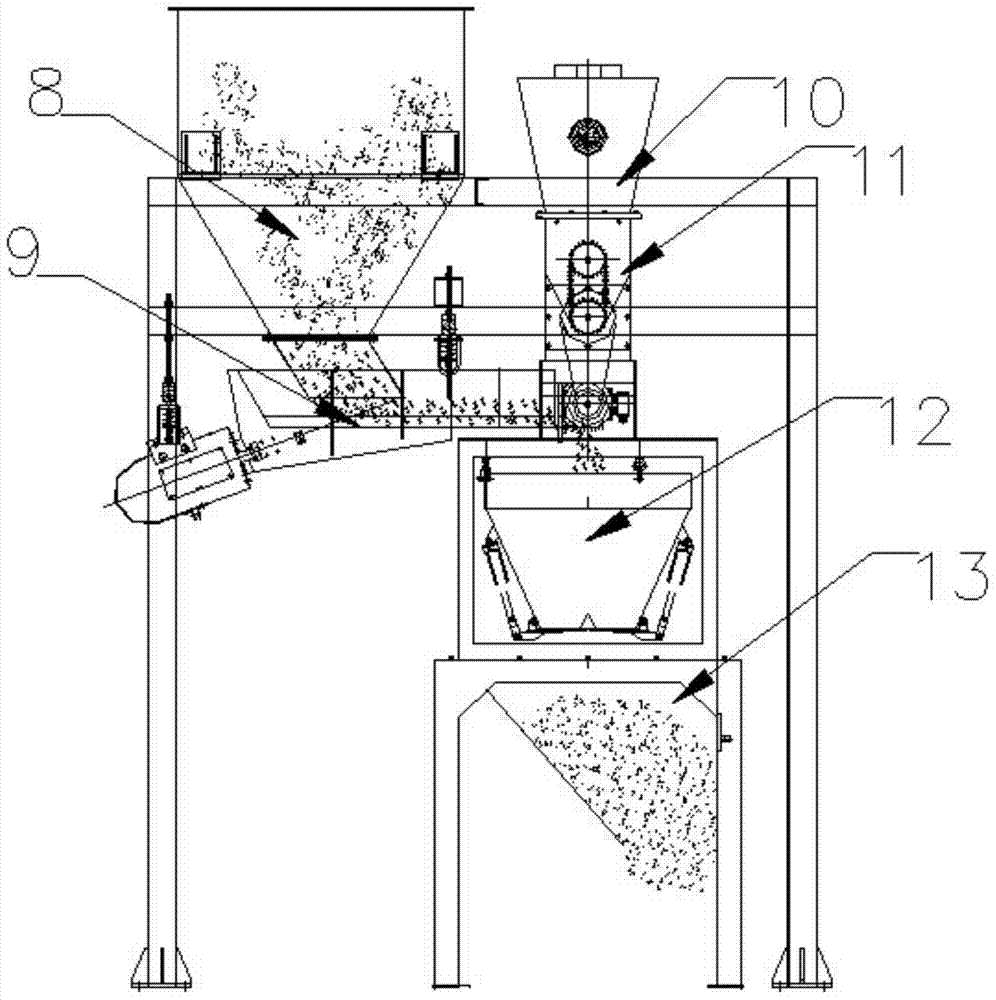

Method used

Image

Examples

Embodiment 1

[0037] Mix 100 parts of natural bituminous ore with 3 parts of light calcium carbonate and crush it into asphalt ore particles with a fineness of 1 cm; then pass through the surface drying tunnel at a speed of 7 meters per minute, the drying temperature is 20 degrees, and the The time is 8 minutes; then it is crushed by a fine crusher until the particle size of all particles is less than 4.75 mm and the particle size is not greater than 1.18 mm accounting for not less than 80% of the total particles; metered packaging.

Embodiment 2

[0039] The natural asphalt ore is crushed into asphalt ore particles with a fineness of 2 cm by a coarse crusher; 100 parts of asphalt ore particles are mixed with 30 parts of heavy calcium carbonate, and then passed through the surface drying tunnel at a speed of 6 meters per minute, and dried The temperature is 30 degrees, and the drying time is 7 minutes; then the bituminous ore particles are crushed by a fine crusher, until the particle size of all particles is less than 4.75 mm and the particle size is not larger than 1.18 mm. The amount of particles is not less than 80% of the total particles; Measured packaging.

Embodiment 3

[0041] The natural bituminous ore is broken into bituminous ore particles with a fineness of 3 cm by a coarse crusher; then it passes through the surface drying tunnel at a speed of 10 meters per minute, the drying temperature is 40 degrees, and the drying time is 6 minutes; Parts of bituminous ore particles correspond to 5 parts of quartz sand powder, and then the bituminous ore particles are crushed by a fine crusher until the particle size of all particles is less than 4.75 mm and the particle size is not greater than 1.18 mm. The amount of the total particles is not less than 80%; metered package.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com