Antibacterial, breathable and water-absorption silver-zinc acrylic ester foam material as well as preparation method and application of antibacterial, breathable and water-absorption silver-zinc acrylic ester foam material

A technology of water-absorbing acrylate and foam materials, applied in absorbent pads, medical science, bandages, etc., can solve problems such as insufficient air permeability, easy breeding of bacteria, and skin allergies, and achieve excellent antibacterial performance, good water absorption, and good air permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

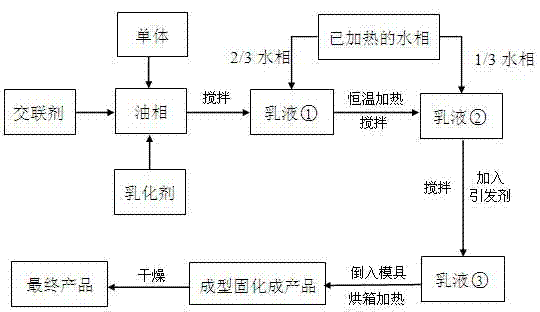

Image

Examples

Embodiment 1

[0051] S1. Prepare the oil phase system, weigh 7.2g of isooctyl acrylate, 0.8g of isooctyl methacrylate, 4.8g of ethylene glycol dimethacrylate, 0.4g of hexanediol diacrylate, and 1.6g of silver titanium Bacteriostatic particles A, Tween-80 1.2g, stir the oil phase evenly for use, wherein the mass ratio of isooctyl acrylate to isooctyl methacrylate is 9:1.

[0052] S2. Prepare the water phase system, weigh 0.096g of calcium chloride, add water to 480g to dissolve it, at this time, the mass fraction of the electrolyte is 0.02%, and wait for use; prepare the initiator phase, and weigh 1.71g of ammonium persulfate , add water to 10g to dissolve, set aside.

[0053] S3. Transfer 320 g of the prepared water phase into a 1000 ml three-necked flask, start stirring, raise the temperature to 75° C., and stir at a speed above 800 rpm, then add the uniformly stirred oil phase and 0.32 g of light calcium carbonate into the three-necked flask , before the emulsion becomes viscous, add 160...

Embodiment 2

[0056] S1. Prepare the oil phase system, weigh 7g of isooctyl acrylate, 1g of isooctyl methacrylate, 4.8g of ethylene glycol dimethacrylate, 0.4g of hexanediol diacrylate, and 1.6g of silver titanium antibacterial Particle A, Tween-80 1.2g, stir the oil phase evenly for use, wherein the mass ratio of isooctyl acrylate to isooctyl methacrylate is 7:1.

[0057] S2. Prepare the water phase system, weigh 0.096g of calcium chloride, add water to 480g to dissolve it, at this time, the mass fraction of the electrolyte is 0.02%, and wait for use; prepare the initiator phase, and weigh 1.71g of ammonium persulfate , add water to 10g to dissolve, set aside.

[0058] S3. Transfer 320 g of the prepared water phase into a 1000 ml three-necked flask, start stirring, raise the temperature to 75° C., and stir at a speed above 800 rpm, then add the uniformly stirred oil phase and 0.32 g of light calcium carbonate into the three-necked flask , before the emulsion becomes viscous, add 160g of t...

Embodiment 3

[0061] S1. Prepare the oil phase system, weigh 12g of isooctyl acrylate, 1.5g of isooctyl methacrylate, 0.4g of ethylene glycol dimethacrylate, 0.4g of hexanediol diacrylate, and 0.8g of silver titanium pH Bacteria particle A, Tween-80 0.8g, stir the oil phase evenly for use, wherein the mass ratio of isooctyl acrylate to isooctyl methacrylate is 8:1.

[0062] S2. Prepare the water phase system, weigh 0.096g of calcium chloride, add water to 480g to dissolve it, at this time, the mass fraction of the electrolyte is 0.02%, and wait for use; prepare the initiator phase, and weigh 1.71g of ammonium persulfate , add water to 10g to dissolve, set aside.

[0063] S3. Transfer 320 g of the prepared water phase into a 1000 ml three-necked flask, start stirring, raise the temperature to 75° C., and stir at a speed above 800 rpm, then add the uniformly stirred oil phase and 0.32 g of light calcium carbonate into the three-necked flask , before the emulsion becomes viscous, add 160g of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com