Rapid dehydration curing agent as well as preparation method and application thereof

A rapid dehydration and curing agent technology, which is applied in the field of newly repaired normal temperature asphalt surface layer and road maintenance and repair, can solve the problems of difficult curing and slow concrete dehydration, and achieve the effect of rapid moisture absorption and strong curing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1) Weigh 500g of mixed aggregate, 47.5g of asphalt mixed at room temperature, 17.5g of rapid dehydration curing agent, and 7.5g of water;

[0030] Step 2) Put the weighed mixed aggregate and fast dehydration curing agent into the mixing pot, stir for 15 seconds, and stir evenly;

[0031] Step 3) Put the weighed water into the mixing pot to moisten the aggregate;

[0032] Step 4) Add the weighed normal temperature mixed asphalt into the mixing pot, and stir for 60s;

[0033] Step 5) Put the ring-shaped test mold on the asphalt felt, mix the mixture that meets the required ratio, pour it into the test mold immediately, scrape it flat, and tamp it 75 times;

[0034] Step 6) After 45 minutes, the sample reaches the initial setting, and the sample is demoulded;

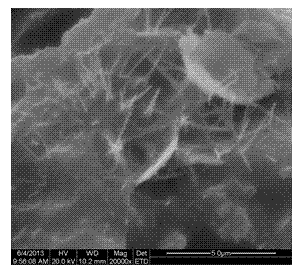

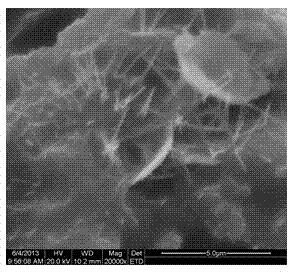

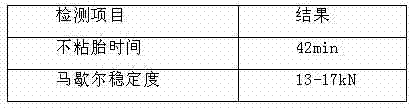

[0035] Step 7) Refer to figure 1 , figure 2 As shown, the detection performance is shown in Table 1.

[0036] Table 1

[0037]

[0038] Step 8) The performance is up to standard, mix the mixture accor...

Embodiment 2

[0042] Step 1) Weigh 500g of mixed aggregate, 50.5g of mixed asphalt at room temperature, 19.0g of rapid dehydration curing agent, and 7.5g of water;

[0043] Step 2) Put the weighed mixed aggregate and fast dehydration curing agent into the mixing pot, stir for 15 seconds, and stir evenly;

[0044] Step 3) Put the weighed water into the mixing pot to moisten the aggregate;

[0045] Step 4) Add the weighed normal temperature mixed asphalt into the mixing pot, and stir for 60 seconds;

[0046] Step 5) Put the ring-shaped test mold on the asphalt felt, mix the mixture that meets the required ratio, pour it into the test mold immediately, scrape it flat, and tamp it 75 times;

[0047] Step 6) After 45 minutes, the sample reaches the initial setting, and the sample is demoulded;

[0048] Step 7) Detection performance, see Table 2.

[0049] Table 2

[0050]

[0051] Step 8) The performance is up to standard, mix the mixture according to steps 1-4, and spread it with a paver;...

Embodiment 3

[0055] Step 1) Weigh 500g of mixed aggregate, 45.0g of mixed asphalt at room temperature, 15.0g of rapid dehydration curing agent, and 7.5g of water;

[0056] Step 2) Put the weighed mixed aggregate and fast dehydration curing agent into the mixing pot, stir for 15 seconds, and stir evenly;

[0057] Step 3) Put the weighed water into the mixing pot to moisten the aggregate;

[0058] Step 4) Add the weighed normal temperature mixed asphalt into the mixing pot, and stir for 60s;

[0059] Step 5) Put the ring-shaped test mold on the asphalt felt, mix the mixture that meets the required ratio, pour it into the test mold immediately, scrape it flat, and tamp it 75 times;

[0060] Step 6) After 45 minutes, the sample reaches the initial setting, and the sample is demoulded;

[0061] Step 7) Detection performance, see Table 3.

[0062] table 3

[0063]

[0064] Step 8) The performance is up to standard, mix the mixture according to steps 1-4, and spread it with a paver;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com