Floating disc type oil sucking device for oil-containing sewage tank

A technology of oily sewage and floating discs, which is applied in the direction of grease/oily substance/floating matter removal devices, water/sludge/sewage treatment, water pollutants, etc., and can solve the problems of inability to effectively remove oil layers, difficulty in accurately controlling distance, and oil absorption efficiency low cost, low cost, easy installation and disassembly, and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

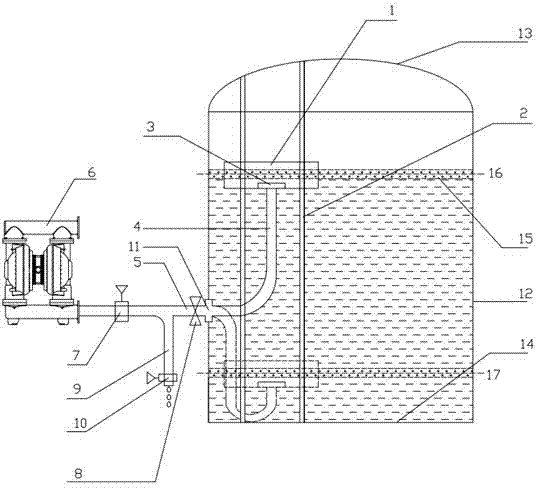

[0026] Such as figure 1 As shown, the standard suction lift of the air diaphragm pump 6 is 6.5m, and the geometric center of the pump suction port 11 is located at 1 / 3 of the height of the oily sewage tank 12 .

[0027] When the height of the oil-water interface 15 is in the state of the high liquid level 16, the shut-off valve 8 is opened. And, close the stop valve 7, open the pipe valve 10, and use the overflow method to drain the oil, so that the oil layer is driven by gravity to flow through the external jumper 9 and be discharged out of the tank.

[0028] When the oil reservoir at the oil-water interface 15 is substantially emptied, and the discharged liquid is mostly water, the shut-off valve 8 is closed to terminate this oil suction operation.

Embodiment 2

[0030] Such as figure 1 As shown, the standard suction lift of the air diaphragm pump 6 is 7.5m, and the geometric center of the pump suction port 11 is located at 1 / 3 of the height of the oily sewage tank 12 .

[0031] When the height of the oil-water interface 15 is in the state of the low liquid level 17, the shut-off valve 8 is opened. And, open the shut-off valve 7, close the pipe valve 10, turn on the air diaphragm pump 6, and adopt the method of vacuuming, so that the oil layer flows through the oil discharge pipeline 5 and is discharged out of the tank.

[0032] When the oil reservoir at the oil-water interface 15 is substantially emptied, and the discharged liquid is mostly water, the shut-off valve 8 is closed to terminate this oil suction operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com