Apparatus and method for producing magnesium sulfate

A magnesium sulfate and sulfuric acid-containing technology, applied in the direction of magnesium sulfate, separation methods, chemical instruments and methods, etc., can solve the problems of poor quality, low evaporation and concentration efficiency, and large steam consumption, so as to reduce dust and impurity content, reduce Desulfurization operation cost, effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

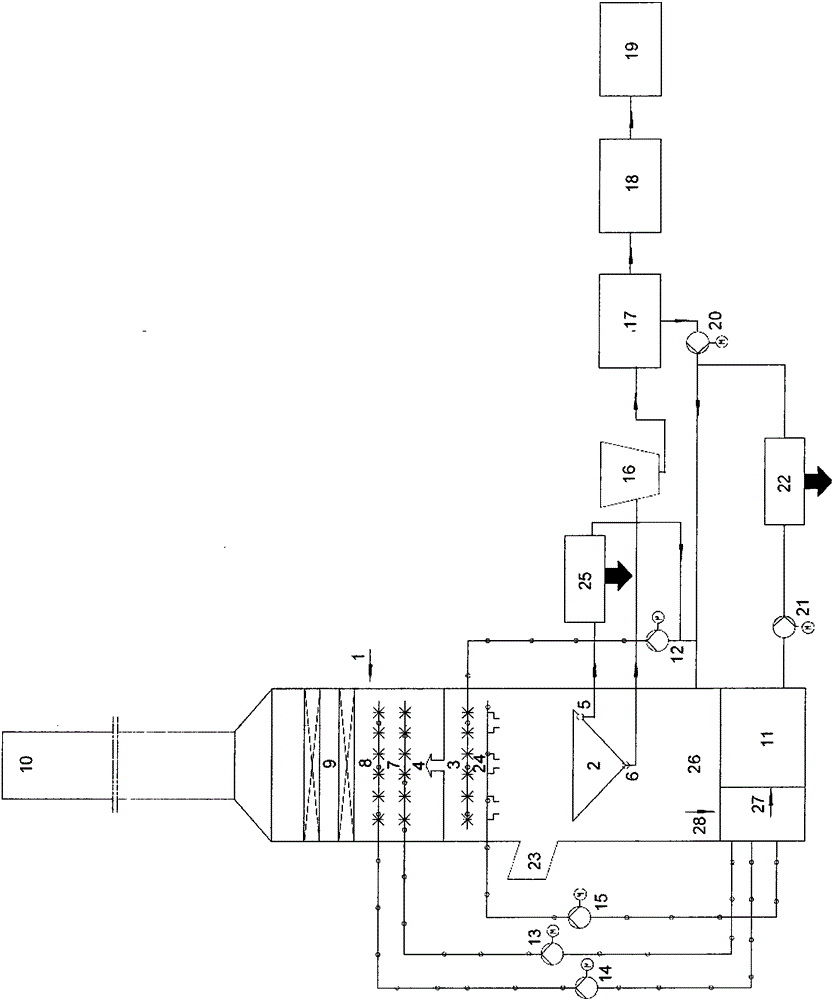

[0058] use figure 1 A specific embodiment of described device producing magnesium sulfate, described method comprises the steps:

[0059] a. The flue gas enters the desulfurization tower 1 from the flue gas inlet 23 of the desulfurization tower 1, enters the evaporation concentration spray layer 3 after passing through the emergency cooling layer 24, and enters the secondary SO 2 Absorption spray layer 7 and tertiary SO 2 The absorption spray layer 8 performs desulfurization absorption reaction, and finally enters the demister 9 for dehydration and demisting, and then directly discharges through the top chimney flue gas outlet 10;

[0060] b. From secondary SO 2 Absorption spray layer 7 and tertiary SO 2 The mixed solution after absorbing sulfur dioxide from the absorbing spray layer 8 enters the slurry circulation tank 11 through the accumulator 4;

[0061] c. The absorption liquid pumped out from the slurry circulation pool 11 is discharged into the first filter 22 throu...

Embodiment 1

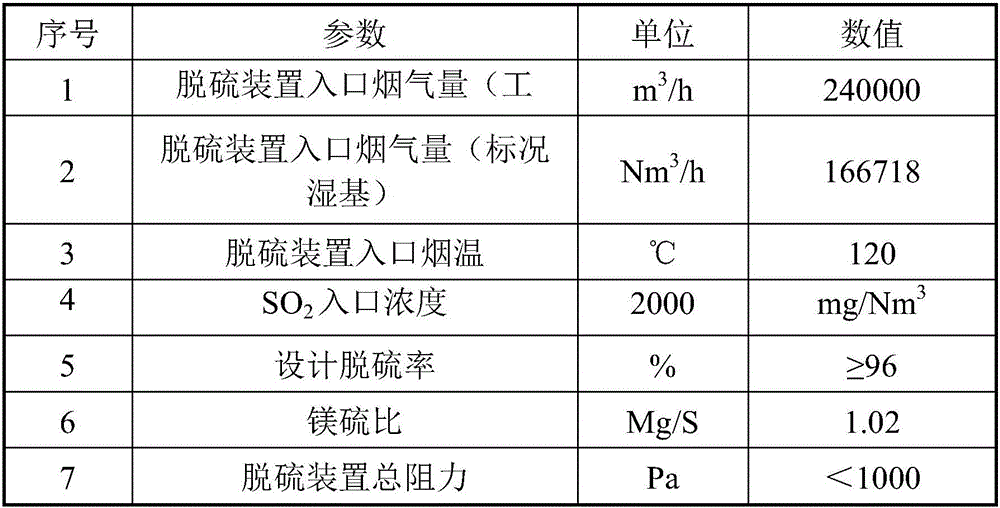

[0066] Example 1 Sintering machine flue gas desulfurization project

[0067] Step 1: Add industrial tap water to magnesium oxide powder to make magnesium hydroxide slurry, and send it to desulfurization tower 1.

[0068] Step 2: Let the sintering machine flue gas (with an oxygen content of 13vt%) with a flow rate of 2.5-3.5m / s and a temperature of 110-180°C enter the desulfurization tower 1 from the flue gas inlet 23 of the desulfurization tower, and transfer the slurry at the bottom of the desulfurization tower The pH value of the circulation pool 11 is controlled between 5.5-7.

[0069] Step 3: Control the pH value of the evaporative concentration slurry pool 26 between 4.5-6.

[0070] Step 4: Pass the secondary SO 2 Absorption circulation pump 13, three-stage SO 2 The absorption circulation pump 14 sends the slurry to the secondary SO 2 Absorption spray layer 7, three-stage SO 2 The absorption spray layer 8, after the absorption reaction, the slurry falls into the ac...

Embodiment 2

[0084] Example 2 Coal-fired boiler flue gas desulfurization project

[0085] The implementation steps of embodiment 2 are exactly the same as embodiment 1 except that the flue gas used is coal-fired boiler flue gas (oxygen content is adjusted to 13vt%).

[0086] For the coal-fired boiler flue gas desulfurization project in Example 2, its operating parameters, emissions and by-product quality are shown in Table 4-5 below.

[0087] Table 4 Working condition parameter list of 200t / h coal-fired boiler flue gas desulfurization project

[0088] serial number project quantity unit 1 Flue gas volume at the inlet of the desulfurization system (working condition) 365000 m 3 / h

[0089] Table 5 Emissions and magnesium sulfate output of coal-fired boiler flue gas desulfurization project

[0090] serial number project quantity unit 1 Flue gas volume at the outlet of the desulfurization unit (working condition) 386085 m 3 / h

[0091] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com