Automatic Floor Cleaner for Belt Conveyors

A belt conveyor, automatic cleaning technology, applied in the direction of conveyor objects, cleaning devices, transportation and packaging, etc., can solve the problems of time-consuming, laborious, dangerous, material waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

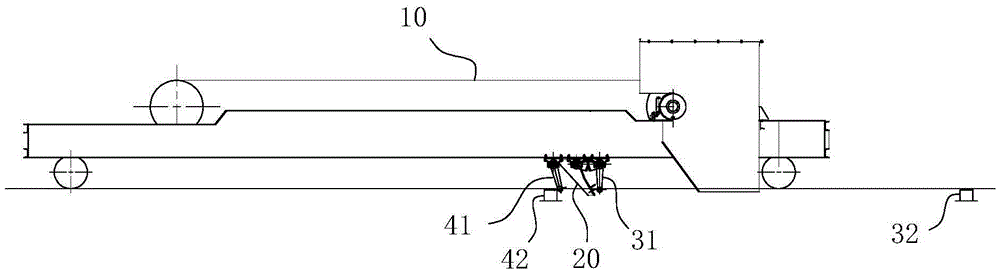

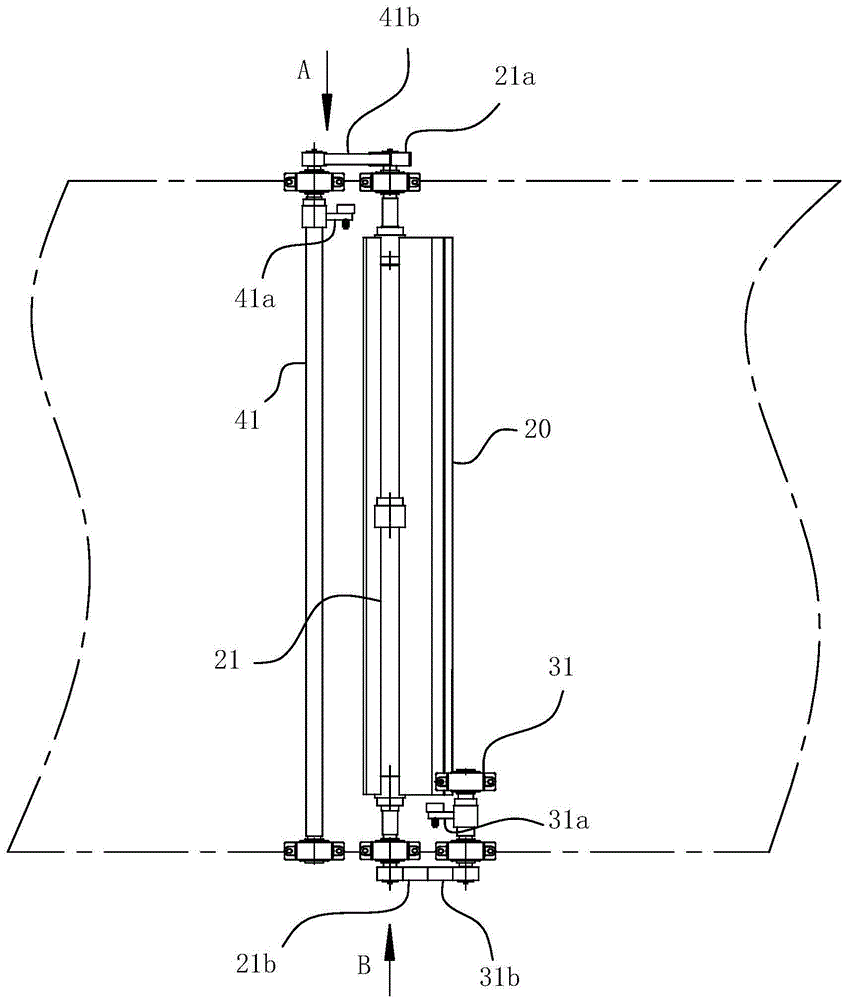

[0038] For ease of understanding, combined here Figure 1-10 The specific implementation structure and work flow of the present invention are described as follows:

[0039] The concrete structure of the present invention is as Figure 1-10 As shown, the specified action limiting function of the front scraper 20 is realized mainly by the front scraper lifting assembly and the front scraper reset assembly with different functions. The solid line arrows in the figure are the direction of action of the trolley 10 , and the dotted line arrows are the direction of the lifting and reset action of the front scraper 20 .

[0040] The specific structure of the present invention includes a walking trolley 10 as a reciprocating power source, three axle sleeves parallel to each other and on the same horizontal line are arranged under the frame of the walking trolley 10, and a rotating shaft and a rotating shaft 21 are correspondingly rotated and sleeved in the axle sleeves. An inclined p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com