Part neck cold heading pattern cutting punching mold

A stamping die and neck technology, applied in the field of cold heading cut flower stamping die for parts neck, can solve the problems of inability to meet the special requirements of cutting lace of parts, the stability needs to be improved, the bottom die is lack of fastening, etc. The effect of fast speed and avoiding horizontal displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

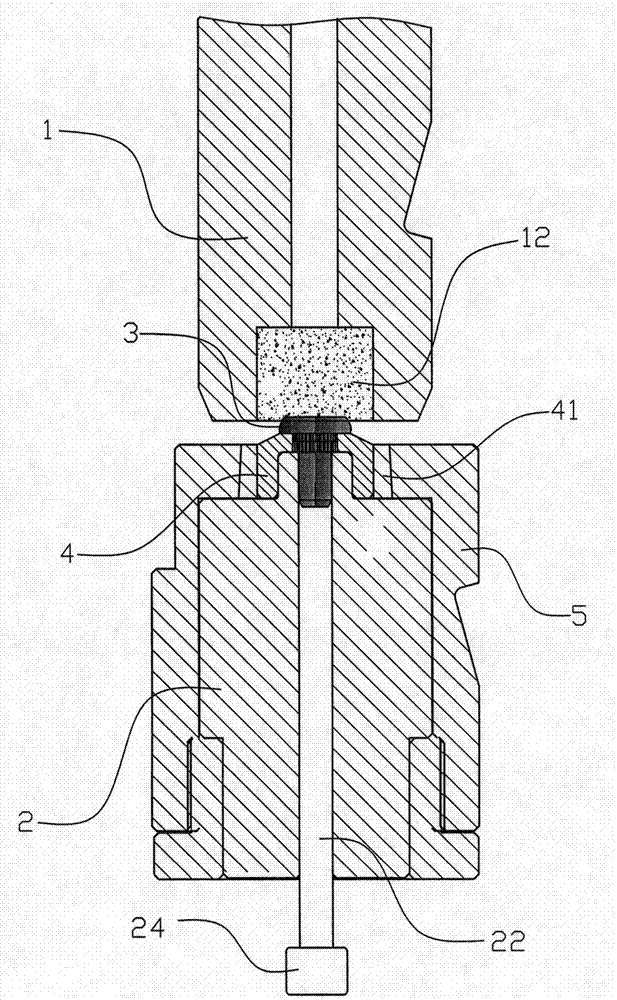

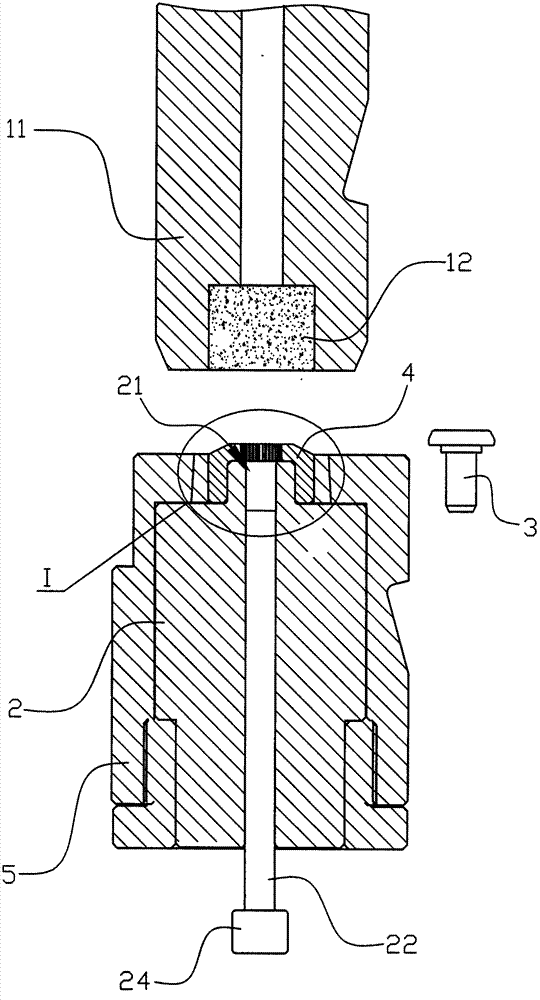

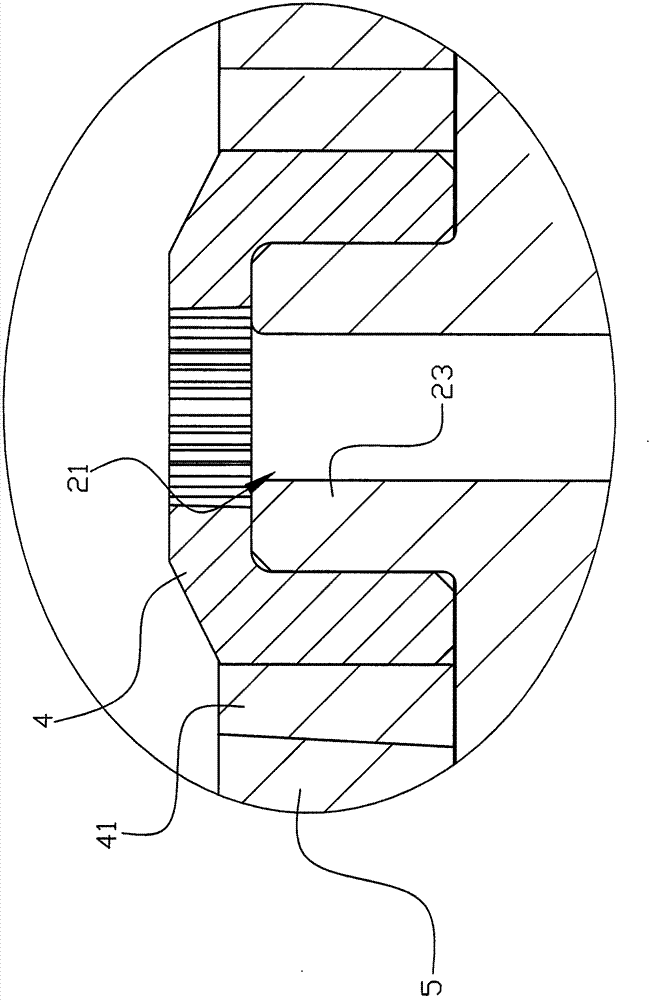

[0015] Such as Figure 1 to Figure 3 As shown, the part neck cold heading cutting pattern stamping die of this embodiment includes an upper die 1 and a lower die, the upper die 1 can move up and down relative to the lower die through a driving device, and the upper die 1 includes an upper die shell 11 1. The stamping block 12 embedded in the bottom of the upper mold shell 11, the lower mold cavity 21 that can place the processed parts is provided in the lower mold, and the lower mold cavity 21 is vertically provided with the processing parts 3 from The through rod 22 ejected in the cavity 21 of the lower die, the through rod 22 can slide up and down through the through hole of the die to extend out of the bottom of the die, and the outer lower die of the cavity 21 of the die is provided with a processing The neck trimming die 4 of the part 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com