Recovery method of gold

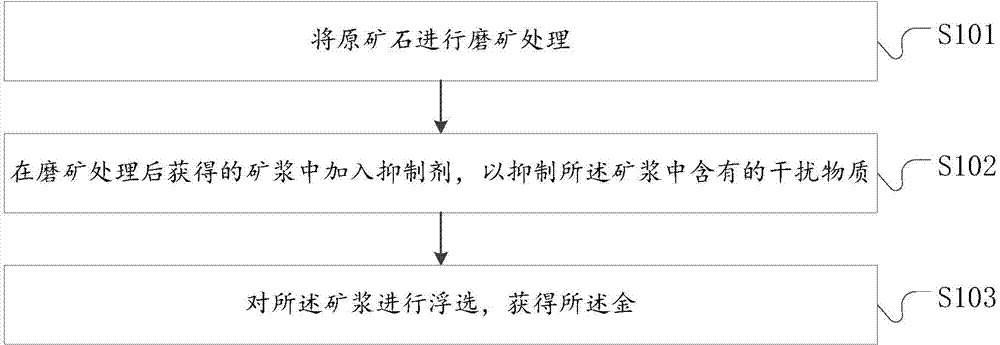

A recovery method and technology of gold ore, applied in the field of recovery, can solve the problems of Carlin-type gold ore flotation without obvious effect, difficult to meet industrial production requirements, low gold concentrate grade and recovery rate, etc., and achieve stable separation index , improve grade, sorting index and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0039]A Carlin-type gold ore, the raw ore contains 3.60g / t gold and 1.59% carbon, when the grinding is at -0.074mm and the percentage is 95%:

[0040] Carboxymethyl cellulose (CMC), sodium silicate and sodium carbonate are used as inhibitors, and three roughing procedures are used, the first roughing is followed by selection, the second roughing and the third roughing After merging, it is selected and finally combined with the concentrate obtained in the first roughing to obtain gold.

[0041] The amount of carboxymethyl cellulose (CMC) in the first roughing selection is 900g / t 原矿石 , Sodium silicate dosage 1800g / t 原矿石 , Sodium carbonate dosage 1500g / t 原矿石 ;

[0042] The dosage of carboxymethyl cellulose (CMC) in the second roughing is 100g / t 原矿石 ;

[0043] No inhibitor was added for the third roughing.

[0044] Gold concentrate with a gold grade of 24.61g / t and a gold recovery rate of 80.42% can be obtained by flotation. The gold grade of the gold concentrate obtained b...

example 2

[0046] A certain Carlin-type gold ore contains 3.81g / t of gold and 1.05% of carbon. When the grinding is at -0.074mm and the percentage is 93%, carboxymethyl cellulose (CMC) and sodium carbonate are used as inhibitors. Two roughing processes are adopted, the first roughing and then separate selection, the second roughing and then separate selection, and finally the concentrate is combined.

[0047] The amount of carboxymethyl cellulose (CMC) in the first rough selection is 1000g / t 原矿石 , Sodium carbonate dosage 2000g / t 原矿石 ; The dosage of carboxymethyl cellulose (CMC) in the second rough selection is 100g / t 原矿石 .

[0048] Gold concentrate with gold grade of 24.85g / t and gold recovery rate of 81.15% can be obtained by flotation. The gold grade of the gold concentrate obtained by the conventional flotation method is 17.00g / t~18.50g / t, and the gold recovery rate is 45.00%~62.74%.

example 3

[0050] A Carlin-type gold ore, the raw ore contains 3.55g / t gold and 1.25% carbon, and when the grinding is at -0.074mm and accounts for 95% of the percentage, carboxymethyl cellulose (CMC) is used as an inhibitor.

[0051] Three roughing processes are adopted, the first roughing is selected separately, the second roughing and the third roughing are combined and then selected, and the concentrate is finally combined. The amount of carboxymethyl cellulose (CMC) in the first rough selection is 800g / t 原矿石 ; The second rough selection of carboxymethyl cellulose (CMC) consumption 120g / t 原矿石 ; No inhibitor was added for the third roughing. Gold concentrate with gold grade of 24.12g / t and gold recovery rate of 80.86% can be obtained by flotation. The gold grade of the gold concentrate obtained by the conventional flotation method is 16.40g / t~17.80g / t, and the gold recovery rate is 40.60%~65.30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com