Anti-accumulation powder grinder

A pulverizer and powder accumulating technology, which is applied in the field of pharmaceutical pulverizers, can solve the problems of affecting operation efficiency, affecting pulverization quality, and difficulty in pulverization, and achieves the effects of compact structure, improved pulverization quality, and avoiding pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

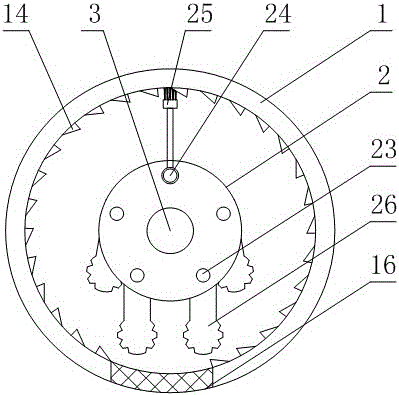

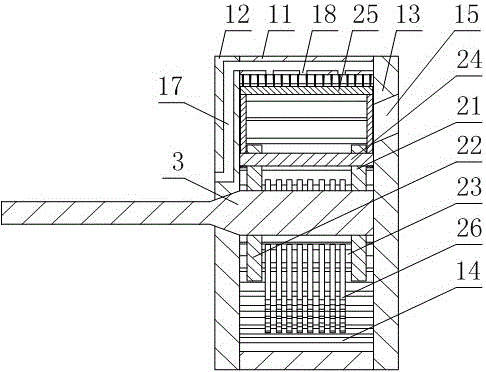

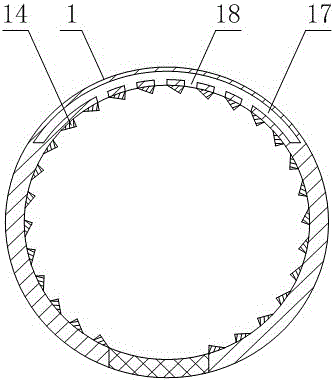

[0018] Such as Figure 1 to Figure 3 As shown, the anti-powder pulverizer includes a sealed pulverizing shell 1, a hammer frame 2, and a drive shaft 3. A plurality of racks 14 are arranged on the inner wall of the pulverizing shell 1, and one end of the drive shaft 3 passes through the The rear wall of the crushing shell 1 is set in the crushing shell 1, the hammer frame 2 is connected to the transmission shaft 3 and set in the crushing shell 1, and the hammer frame 2 is provided with a hammer fixing column 23 and the hairbrush fixing column 24, the hammer blade fixing column 23 is connected with a plurality of hammer blades 26 that can rotate along the axis of the hammer blade fixing column 23, and the hairbrush fixing column 24 is fixedly connected with a hair brush for preventing the rack 14 from accumulating powder. brush 25, the crushing shell 1 is provided with an air duct 17 in the area between its outer wall and the inner wall, and the inner wall of the crushing shell ...

Embodiment 2

[0021] This embodiment makes the following further limitations on the basis of Embodiment 1: the hammer frame 2 includes a front fixed plate 21 and a rear fixed plate 22, the two ends of the hammer fixed column 23 and the brush fixed column Both ends of 24 are connected with front fixed disk 21 and rear fixed disk 22 respectively. In this embodiment, in order to avoid the mutual influence between the hammer piece 26 and the brush handle during the crushing process, the hammer piece 26 can be arranged in the area between the front fixed disk 21 and the rear fixed disk 22, and the hairbrush handle can be arranged on the front fixed disk. Both sides of the disc 21 and the rear fixed disc 22.

Embodiment 3

[0023] In this embodiment, the following further limitations are made on the basis of Embodiment 2: the crushing shell 1 includes a cylinder 11 with openings at both front and rear ends; The rear cover 12 and the front cover 13 are fixedly connected to the front end of the cylinder body 11 and close the front end opening of the cylinder body 11 . In this embodiment, a rack 14 can be provided on the inner wall of the barrel 11 , the transmission shaft 3 can be installed inside the barrel 11 through the rear cover 12 , and the hammer holder 2 is also arranged inside the barrel 11 . In order to make the hammer 26 better cooperate with the rack 14 , the front fixed disk 21 can be arranged at the front opening of the cylinder 11 , and the rear fixed disk 22 can be arranged at the rear opening of the cylinder 11 . At this time, in order to ensure the feasibility of the rotation of the front fixed plate 21 and the rear fixed plate 22, the front cover 13 can be formed by the convexity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com