Granular flour cold-pressing system

A cold processing and flour technology, applied in application, grain processing, grain milling, etc., can solve the problems of uneven flour particles, damage to flour nutrients, and high processing temperature, achieve uniform flour particles, improve production efficiency, and facilitate reprocessing. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

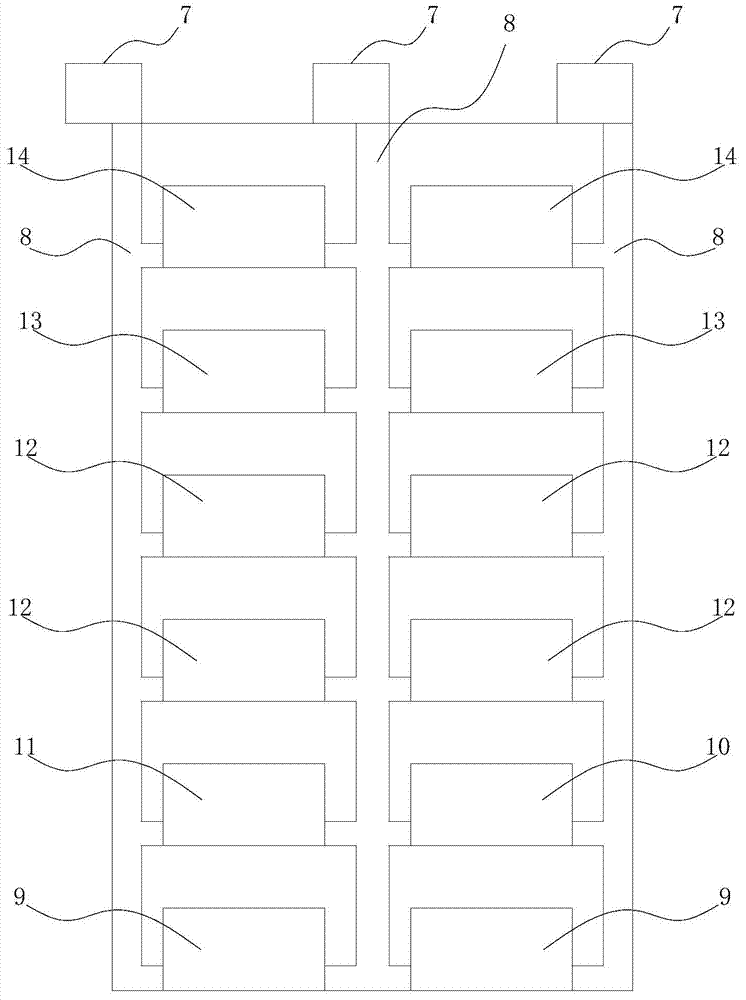

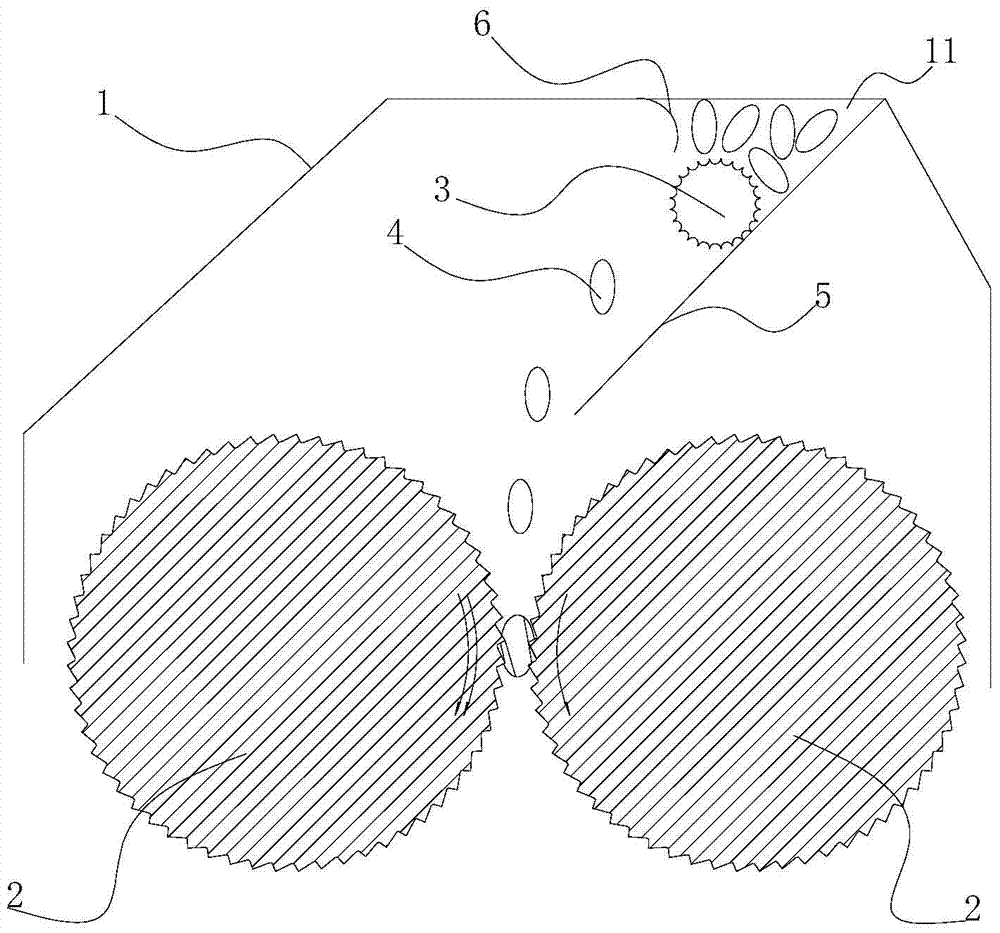

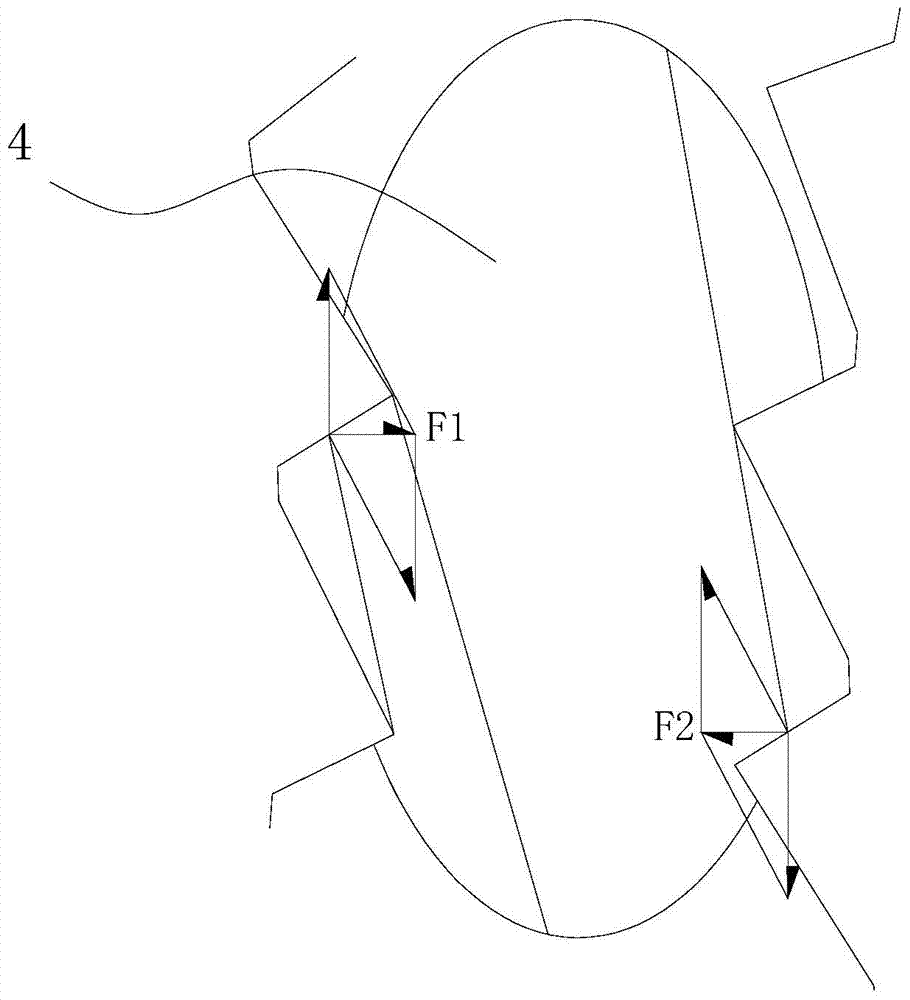

[0020] see figure 1 , a schematic diagram of the structure of a granular flour cold processing system. In actual production, it will be more complicated than the schematic diagram. For example, the layout of the pipeline 8 will be more complicated, but the working principle is the same. It consists of a processing workshop with multiple floors. In this embodiment, there are six floors, and the pipelines 8 used to transport wheat grains are connected between the floors, and each floor is provided with one or more processing equipment involved in the flour processing process, and the pipelines 8 are pumped. The machine control lifts the wheat grains to the top of the floor, and the pipeline 8 is also connected to the corresponding processing equipment in each floor. The wheat grains are processed layer by layer along the pipeline from the top floor of the floor. The processing workshop is also equipped with a temperature and humidity control device to control the temperature of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com