a temperature control mechanism

A technology of temperature control mechanism and temperature control switch, which is applied in the direction of using electric means for temperature control, heating device, water boiling appliance, etc. The effect of low cost, reliable control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

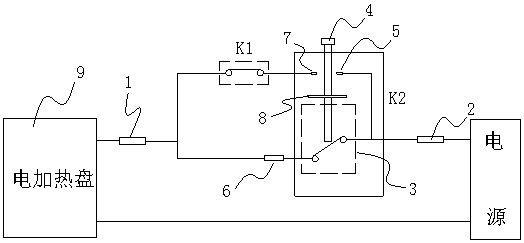

[0019] As shown in the figure, the temperature control mechanism of this embodiment includes a first terminal 1, a second terminal 2, a sudden temperature control switch K1 and a steam temperature control switch K2. When the temperature control switch K1 is lower than the operating temperature Connected, and disconnected when it is higher than the reset temperature, the reset temperature is higher than the action temperature; the steam temperature control switch K2 includes a main body 3 and a tappet 4, and the tappet 4 is movably installed on the shell of the main body 3 , the main body 3 is provided with an input terminal 5 and an output terminal 6, and the main body 3 pops up the tappet 4 when the temperature is higher than a predetermined temperature so as to disconnect the input terminal 5 and the output terminal 6; the shell of the main body 3 The body is also provided with a thermal insulation terminal 7, the thermal insulation terminal 7 and the input terminal 5 are fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com