Sleeve-retractable type automatic opener-mutgun

A telescopic and automatic technology, used in furnaces, lighting and heating equipment, furnace components, etc., can solve problems such as poor safety, harsh working environment, and labor-intensive workers, achieve high reliability, reduce manual operations, and save work. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

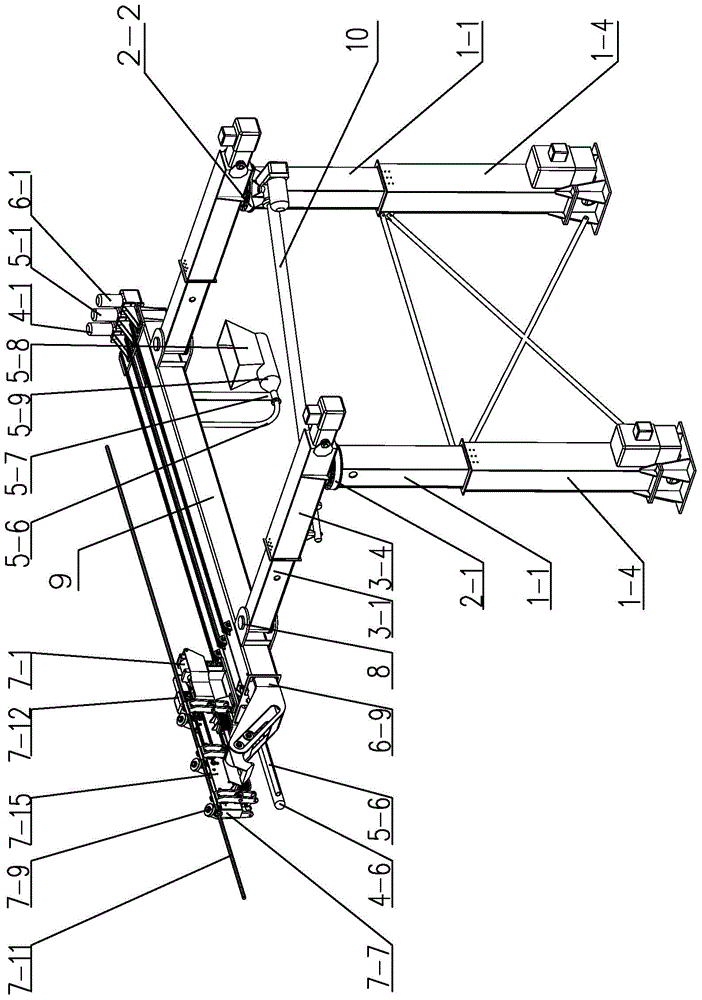

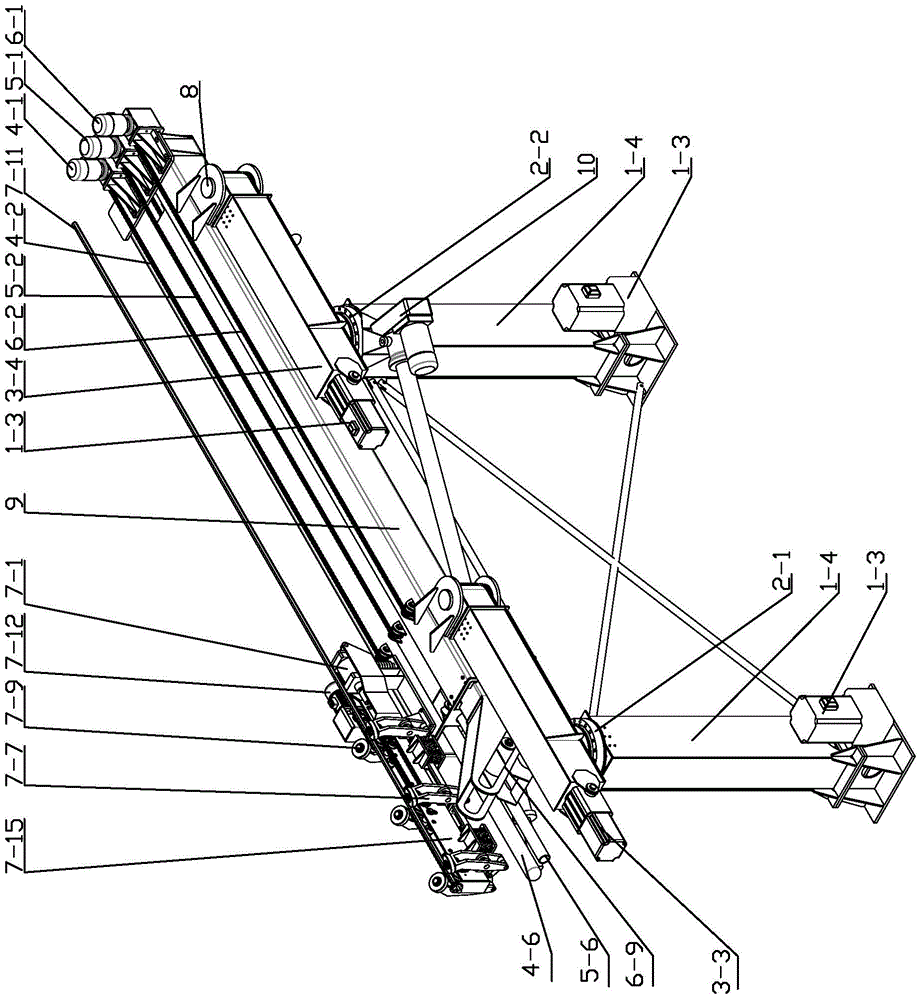

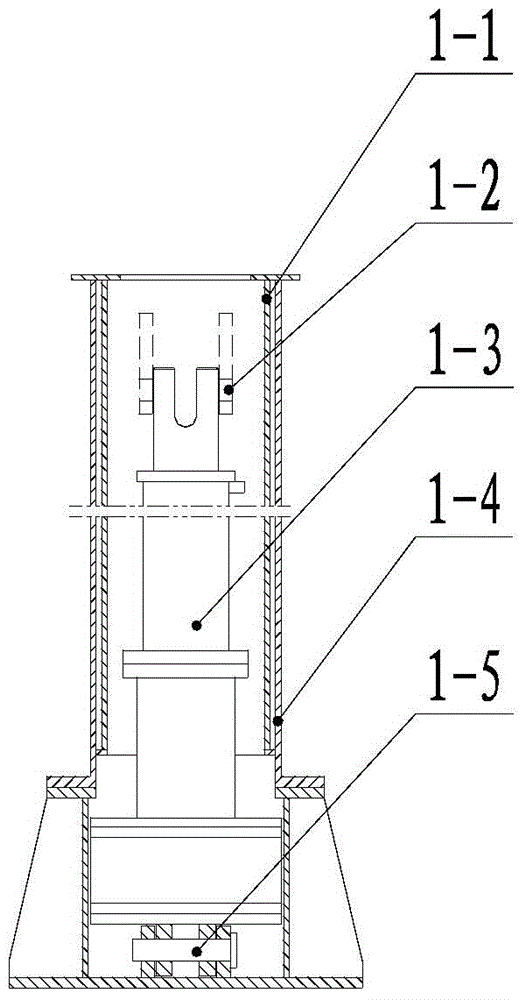

[0024] A sleeve telescopic automatic eye opening machine is characterized in that: the lower parts of the two slewing supports 2-1, 2-2 are respectively fastened to the upper ends of the two vertical telescopic arms 1 fixed on the ground. The tail portions of the two horizontal telescopic arms 3 are respectively fastened to the tops of the slewing bearings 2-1, 2-2 and the front ends are connected to the horizontal working platform 9 through pin shafts 8 . The working platform 9 has three parallel steel rectangular cross-section passages, which are hinged with the horizontal inner sleeve 3-4 through the pin shaft 8. The burn-through mechanism 4, the hole blocking mechanism 5, and the slag removing mechanism 6 are respectively arranged inside the three rectangular cross-section channels of the working platform 9. The slag removing mechanism 6 is near the horizontal telescopic arm 3, and the hole blocking mechanism 5 is in the middle. Arm 3 is the burn through mechanism 4 . And...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com