On-site dynamic balance method of vertical water pump

A technology for on-site dynamic balancing and water pumps, applied in non-variable pumps, components of pumping devices for elastic fluids, pumps, etc., can solve problems such as satisfactory level, low sensitivity to aggravation, and reduced amplitude of unmeasured points , to achieve the effect of improving the success rate, enriching the processing methods, and improving the efficiency of solving vibration faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

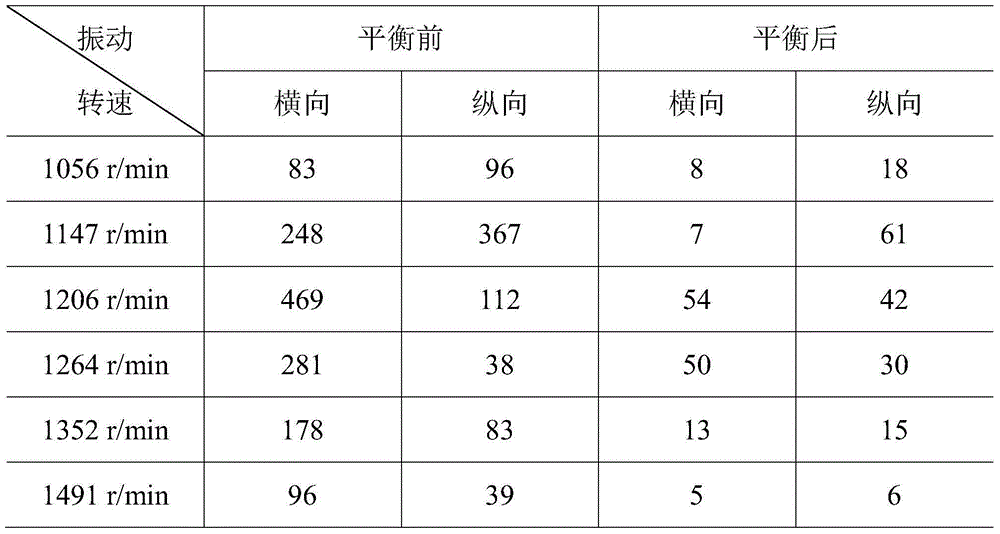

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] The purpose of the present invention is to further enrich the on-site dynamic balance processing means of vertical water pumps, improve the success rate of solving the vibration problems of vertical water pumps through on-site dynamic balance, greatly improve the efficiency of solving vibration failures, and ensure the safe operation of equipment to reduce losses for enterprises.

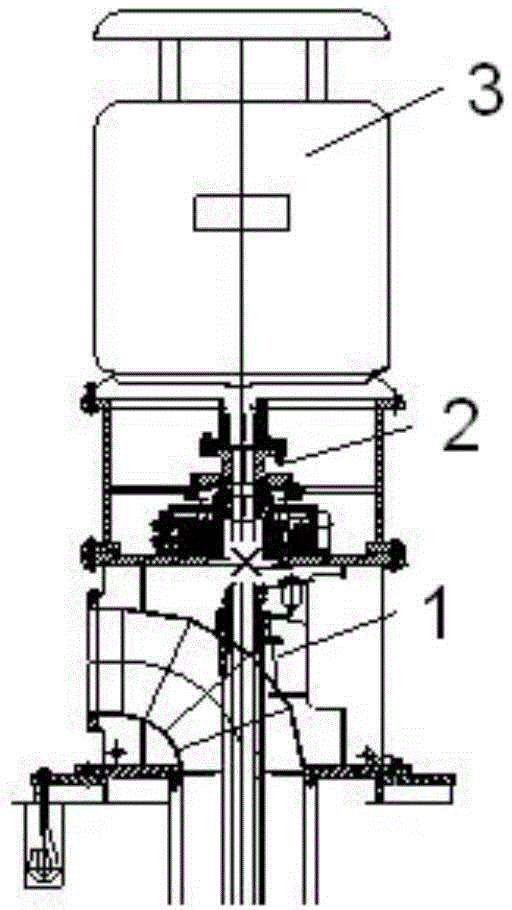

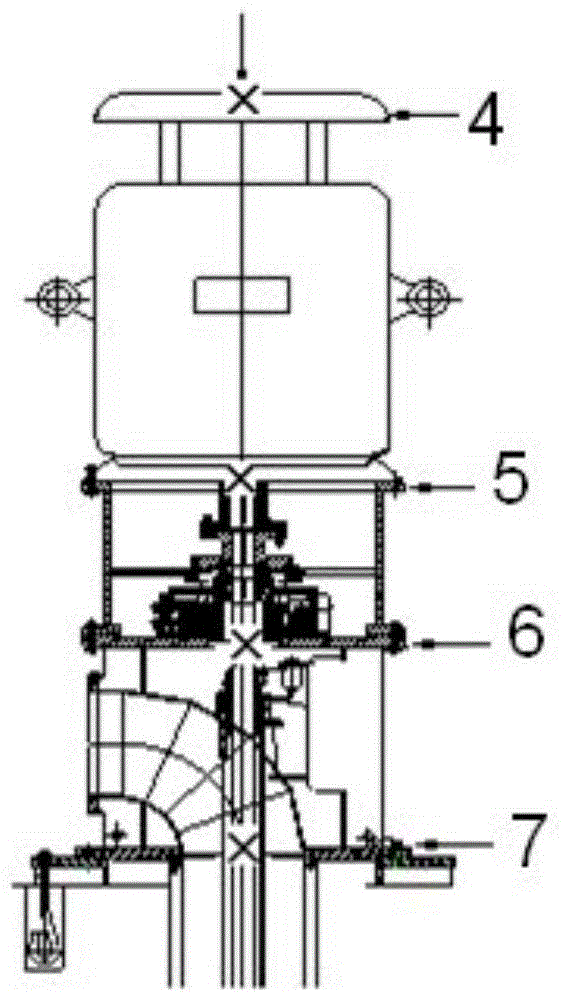

[0027] The field dynamic balancing method of vertical water pump of the present invention, see figure 1 , the vertical water pump includes a motor 3 and a water pump 1 connected together by a coupling 2; including the following steps:

[0028] Existing vertical water pump top motor top fan outside has exposed shaft end, under the condition of not dismantling the motor, measure the size of the exposed journal, process a roulette and drill and tap to install the balance screw,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com