Method of using loading force to measure rod pumped well annular space working fluid level and work condition diagnosis method

A technology for pumping well and dynamic liquid level, which is applied in the measurement of the liquid level position of the pumping well in the oil field and the field of oil production in the oil field. Problems such as the position of the force zero point of the power map, to achieve the effects of reliable and timely energy saving, efficiency improvement, accuracy improvement, and less test parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0046] Specific embodiments one, this embodiment is described a kind of process of measuring the method for pumping well annulus fluid level with load force is:

[0047] During the normal working process of the pumping unit, the wellhead suspension point load force of the pumping well is collected in real time at high speed, and the data collection speed is greater than or equal to 20 times per second, and the time when the crank of the pumping unit reaches the top dead center of the corresponding pumping unit and the time when it is lowered are determined. dead moment

[0048] Step 1. When the working condition parameters need to be measured, the coefficient correction is performed first:

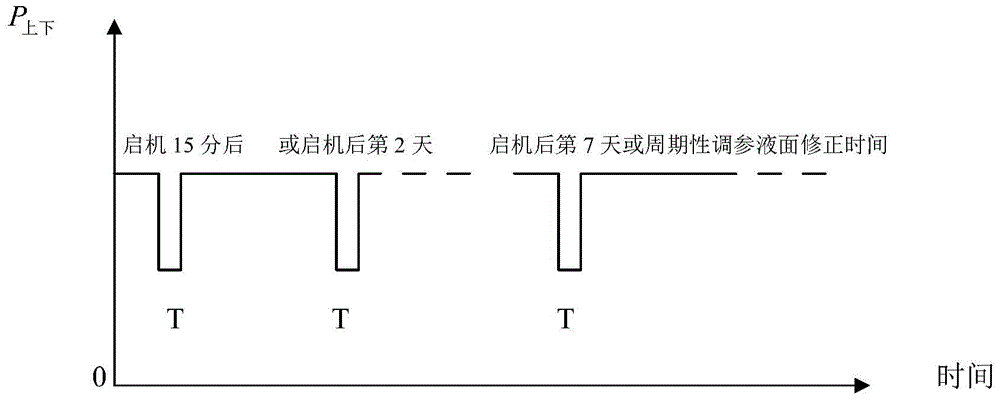

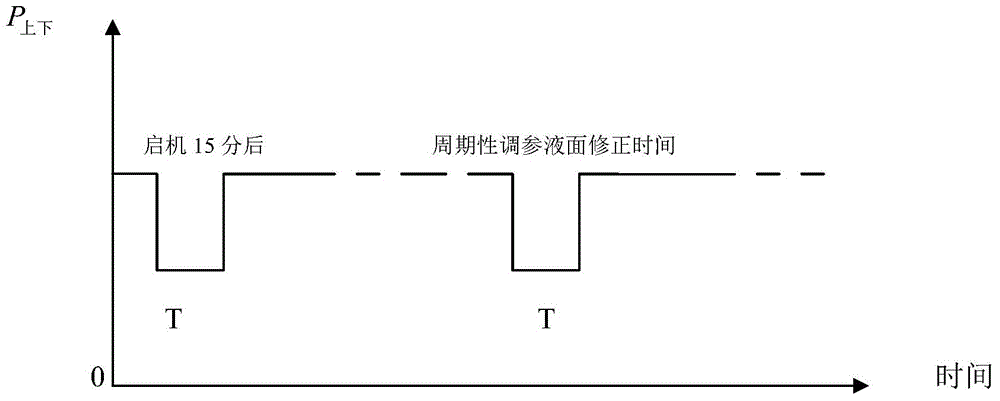

[0049] Adjust the parameters of the pumping well, specifically to control the stroke frequency of the pumping well from the normal operation N to the N after the parameter adjustment 1 , N 1 ≠N and continue to run for a time T, and then return to the stroke times N of normal operation ag...

specific Embodiment approach 2

[0069] Specific embodiment 2. This embodiment is a further limitation of the method for measuring the dynamic liquid level in the annulus of the pumping well with the load force described in the first specific embodiment. In this embodiment, the dynamic liquid level HY of the annular space is obtained. The method is based on the formula:

[0070] HY=(P 上下 -K) / F p

[0071] Obtain the dynamic liquid level HY of the annular space, where: F p Indicates the cross-sectional area of the pumping plunger of the pumping well.

[0072] In the prior art, the method of obtaining the dynamic liquid level in the annular space is based on the mathematical model formula HY=P 上下 / F p get. In this embodiment, when measuring the dynamic liquid level in the annular space, the difference f p ×HY×γ 密 g is related to the weight of the dynamic liquid surface in the annular space, through the change of the actual load force P during the parameter adjustment process 上下 To establish this varia...

specific Embodiment approach 3

[0074] Specific Embodiment 3. This embodiment is a further limitation of the method for measuring the annular dynamic fluid level of the pumping well with the load force described in the specific embodiment 2. In this embodiment, it also includes calculating and obtaining the annular dynamic fluid level. In the step of surface acceleration data a, the obtained annulus dynamic liquid level is corrected by using the formula HY=HY / (1+a) according to the velocity data a to obtain the final annulus dynamic liquid level HY.

[0075] In this embodiment, in the process of measuring the annular dynamic liquid level, the step of measuring the annular space dynamic liquid surface acceleration a is added, and the obtained annular space dynamic liquid level HY is corrected by the acceleration a, thereby eliminating the The influence of the acceleration on the measurement result makes the measurement result closer to the actual value.

[0076] The acceleration a can be based on the formula ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com