Infrared thermal wave based non-destructive testing system for wind turbine blades

A technology of wind power generators and infrared thermal waves, which is applied to rotorcraft, motor vehicles, aircraft parts, etc., can solve the problems of increasing the operating cost of wind turbines, lengthening the blade size, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

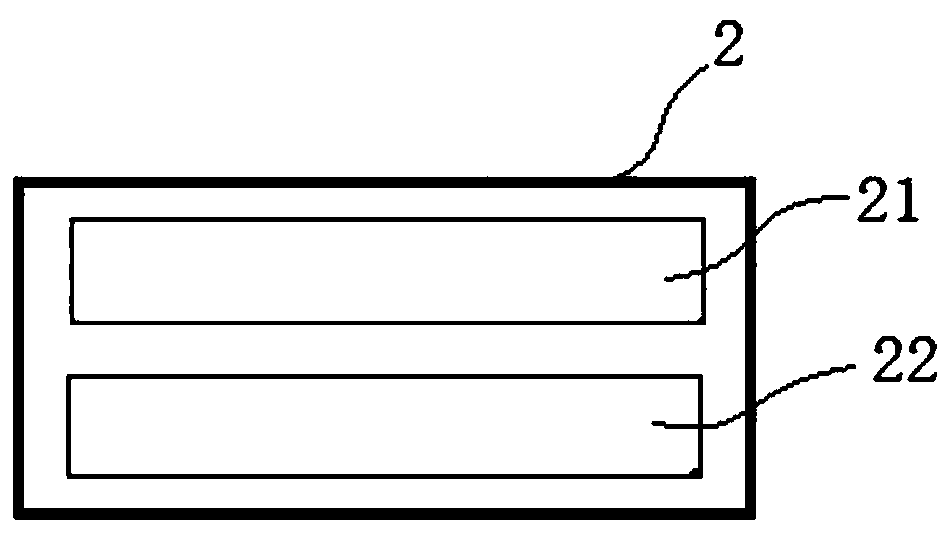

[0027] see figure 1 , figure 2 , image 3 , a non-destructive testing system for wind turbine blades based on infrared thermal waves provided by an embodiment of the present invention, such as figure 1 , figure 2 , image 3 As shown, the system may include a remote-controlled aircraft 1, an infrared thermal wave detection component 2 and a control component 3; the infrared thermal wave detection component 2 is connected to the remote-controlled aircraft 1; the remote-controlled aircraft 1 and the infrared thermal wave detection The components 2 are communicably connected with the control component 3 respectively; specifically, the remote control aircraft and the infrared thermal wave detection component are respectively communicably connected with the control component through a low-frequency wireless microwave signal transmission component.

[0028] The remote-controlled aircraft 1 is used to receive the flight control instruction sent by the control component, so as to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com