Composite material substation structure

A composite material and substation technology, which is applied in the field of composite substation structure, can solve the problems of poor lightning protection and earthquake resistance, large frame height and width, and large occupied area, so as to reduce the size of electrical layout and reduce the occupied area , the effect of long operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

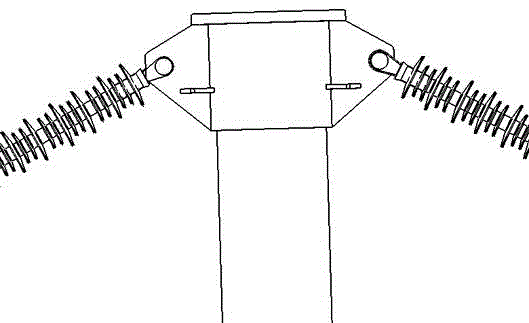

[0024] Embodiment one: if Figure 1 to Figure 7 , Figure 10 As shown, the composite material substation frame provided by the embodiment of the present invention, the main frame structure includes a composite material pipe member herringbone column 1, end support 2, beam 6, ground wire column 3, diagonal stay rod 5, and wire hanging pipe clamp 7, Hanging line pipe clamp 7 comprises two semicircular hoops, and the two ends are respectively connected by hinged bolts 10, wherein one end of one piece is integrally or separately suspended with an extended hanging line plate 11.

[0025] The herringbone column 1 includes the top connector of the herringbone column and the column body of the herringbone column. The ground wire column interface and the beam interface are respectively connected to the column body of the herringbone column through the top connector of the herringbone column. The top connector of the herringbone column is A trapezoidal structure, the trapezoidal struct...

Embodiment 2

[0028] Embodiment two: see in conjunction with Figure 8 to Figure 9 As shown, the beam 6 of the embodiment of the present invention is replaced by a composite material lattice beam, and the structure of the connector at the top of the herringbone column is changed to be suitable for the installation of the frame beam, forming the second embodiment of the present invention. The implementation manners of the embodiments are the same and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com