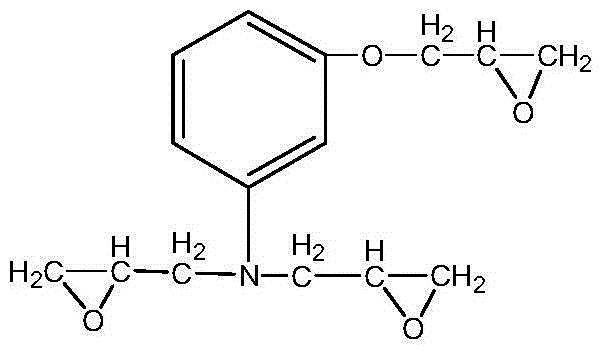

Preparation method of triglycidyl-meta-aminophenol epoxy resin

A technology of triglycidol and aminophenol, applied in the direction of organic chemistry, can solve the problems of exceeding the stoichiometric amount and impossible to achieve complete cyclization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Fill epichlorohydrin 2944g and benzyldiethylammonium chloride catalyst 108g in the 5000mL four-neck round-bottomed flask that is equipped with stirrer, thermometer, nitrogen inlet pipe, dropping funnel, condensing tube and oil-water separator, in Stirring began to heat up, at the same time add m-aminophenol 432g, m-aminophenol was added dropwise in 5 times, the interval between each drop was 25min, after the dropwise addition of m-aminophenol was completed, reacted at 45°C for 6.5 hr, then add 480g of sodium hydroxide at 53°C / 0.065MPa under vacuum pressure, maintain the ring closure reaction for 2.5hr, then release the vacuum, evaporate epichlorohydrin, add 1800mL toluene to the reaction solution to extract triglycidyl-m-amino Phenol epoxy resin, after 3 times of water washing and delamination, get the oil phase, evaporate toluene to obtain reddish-brown liquid triglycidyl-m-aminophenol epoxy resin product, this resin has a viscosity (measured at 25°C) of 7500mPa S, The...

Embodiment 2

[0024] In addition to adding 3312 g of epichlorohydrin and 130 g of benzyltriethylammonium bromide in the addition reaction stage of step (1), the reaction temperature is 50 ° C, and the reaction time is 7 hr. Sodium 130g, 50 ℃ of temperature of reaction, tightness of vacuum 0.07MPa, outside the reaction time 2hr, other prescription and operating steps are all with embodiment 1, and the triglycidyl-m-aminophenol epoxy resin product that obtains has viscosity (25 ℃ measures ) 8000mPa S, epoxy equivalent 9.4eq / Kg; Based on 100 parts by weight of the above-mentioned triglycidyl-m-aminophenol epoxy resin product and 160 parts by weight of methyl endomethine tetrahydrophthalic anhydride Uniformly mixed and solidified according to the conditions of Example 1, the performance index of the sample is: Tg241 ° C, impact strength 20KJ / m 2 , Bending strength 190MPa, tensile strength 70MPa.

Embodiment 3

[0026] In addition to adding 2576 g of epichlorohydrin and 86 g of benzyltrimethylammonium chloride in the addition reaction stage of step (1), the reaction temperature is 45 ° C, and the reaction time is 6 hours. Sodium 512g, temperature of reaction 47 ℃, vacuum tightness 0.06MPa, outside reaction 3hr, other prescription and operating steps are all with embodiment 1, the triglycidyl-m-aminophenol epoxy resin product that obtains has viscosity (25 ℃ measures ) 7000mPa S, epoxy equivalent 9.0eq / Kg; Based on 100 parts by weight of the above-mentioned triglycidyl-m-aminophenol epoxy resin product and 140 parts by weight of methyl endomethine tetrahydrophthalic anhydride Uniformly mixed and solidified according to the conditions of Example 1, the performance index of the sample is: Tg241 ° C, impact strength 16KJ / m 2 , Bending strength 180MPa, tensile strength 50MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com