Elevator damping device with adaptability

A damping device and adaptable technology, applied in transportation and packaging, shock absorbers, mechanical equipment, etc., can solve the problems of passenger danger, inability to use elastic coefficient springs, complex structure, etc., to improve comfort and reliability, The effect of smooth damping force and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

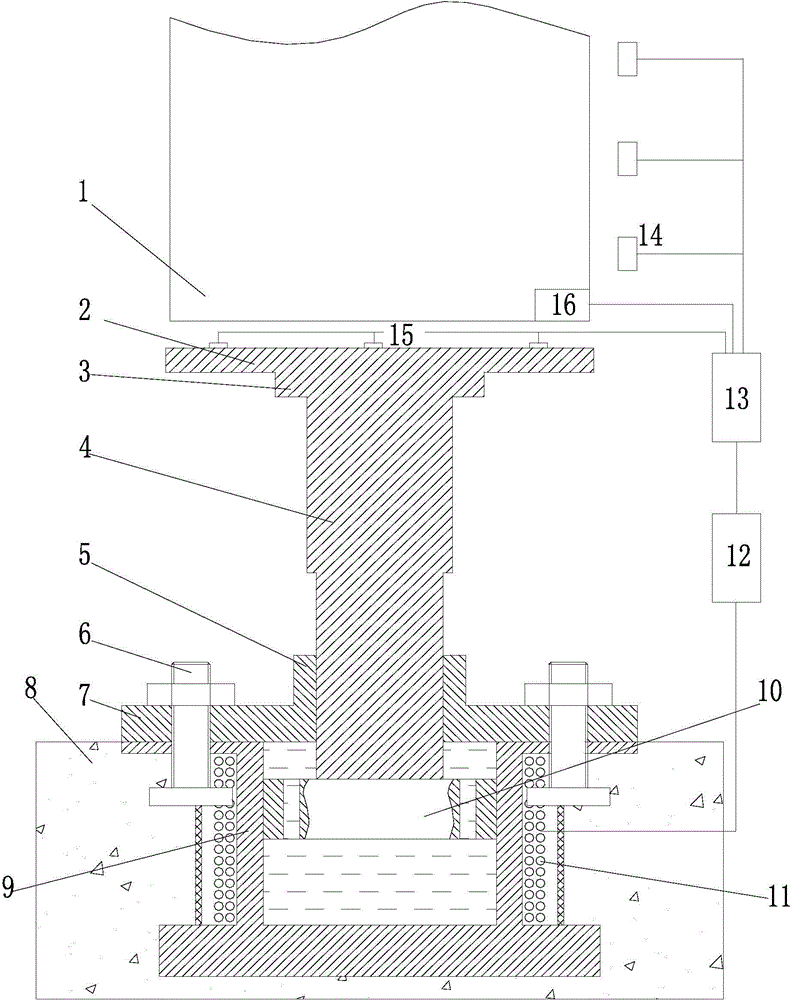

[0025] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure: the elevator of this embodiment has an adaptive damping device, including a magnetorheological damping body and a control system;

[0026] The control system includes:

[0027] The electromagnetic coil 11 is used to provide an electromagnetic field for the magnetorheological damping body;

[0028] A power supply unit 12, configured to provide power for the electromagnetic coil;

[0029] The falling parameter detection unit is used to detect the falling parameter of the elevator car body 1;

[0030] The central processing unit 13 is configured to receive the data signal of the drop parameter detection unit and issue a power supply command to the power supply unit according to the signal.

[0031] The elevator casing 1 will have different speeds and inertias according to different heights and loads during the fall process, so for the buffer device, it is necessary to provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com