A connection method between the front riser, the main beam and the keel flat beam and the vehicle frame thereof

A connection method and riser technology, which can be used in bicycle racks, bicycle accessories, transportation and packaging, etc., can solve the problems of large welding workload and difficult to bear heavy loads, and can increase the area, avoid thermal deformation, and reduce welding seams. effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

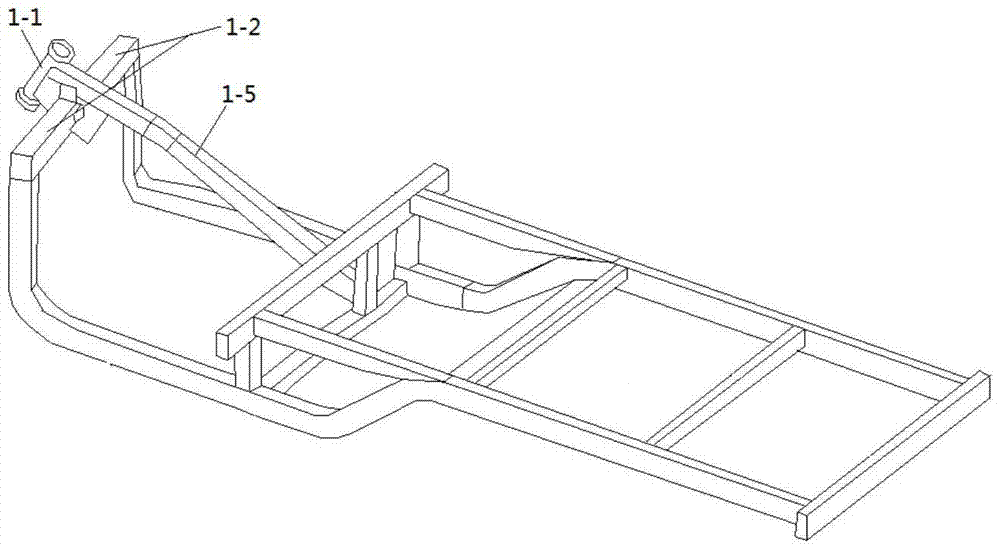

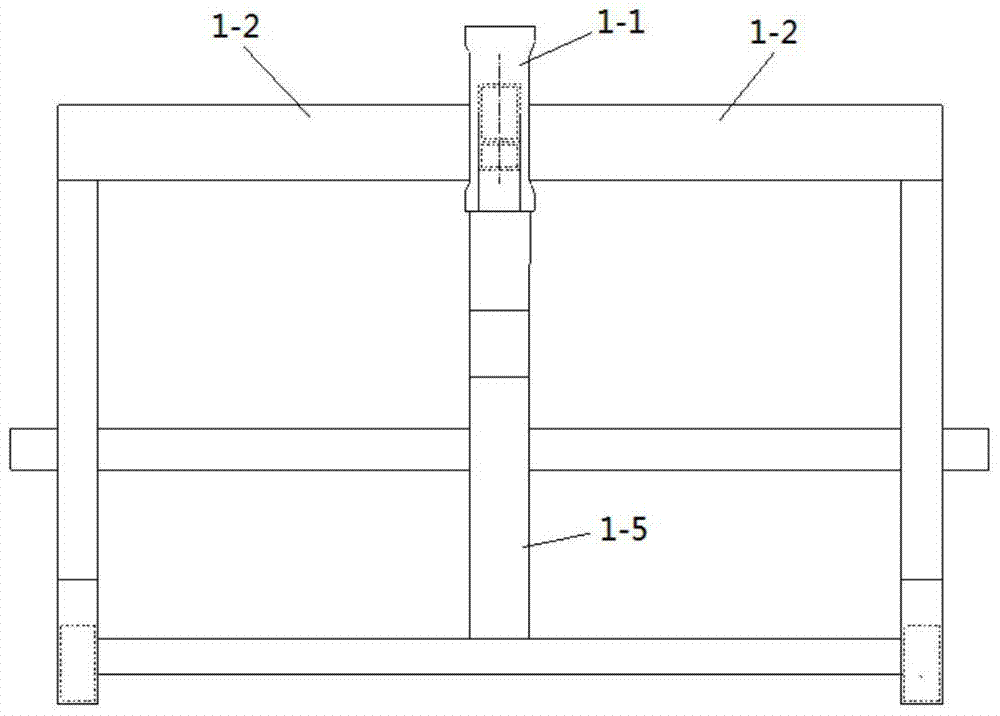

[0029] Without loss of generality, Figure 5-7 As shown, the present invention provides a connection method between the front riser, the main girder and the keel flat girder. The method is divided into the following steps:

[0030] Make a triangular prism connector 1, the triangular prism at least includes two bottom surfaces and one side surface required to form a straight triangular prism, the number of triangular prism connectors 1 is two, respectively the first connector a and the second connector b, The bottom surface of the triangular prism connector 1 is a right triangle, the height of the triangular prism connector 1 matches the width of the cross-section of the keel flat beam 2, and the lengths of the two sides of the right triangle are 20-40cm. Part 1 is made of iron or steel;

[0031] The front end of the main girder 5 is fastened to the side of the headstock riser 4 by welding;

[0032] After attaching the midpoint of the upper end surface of the keel flat beam 6...

Embodiment 2

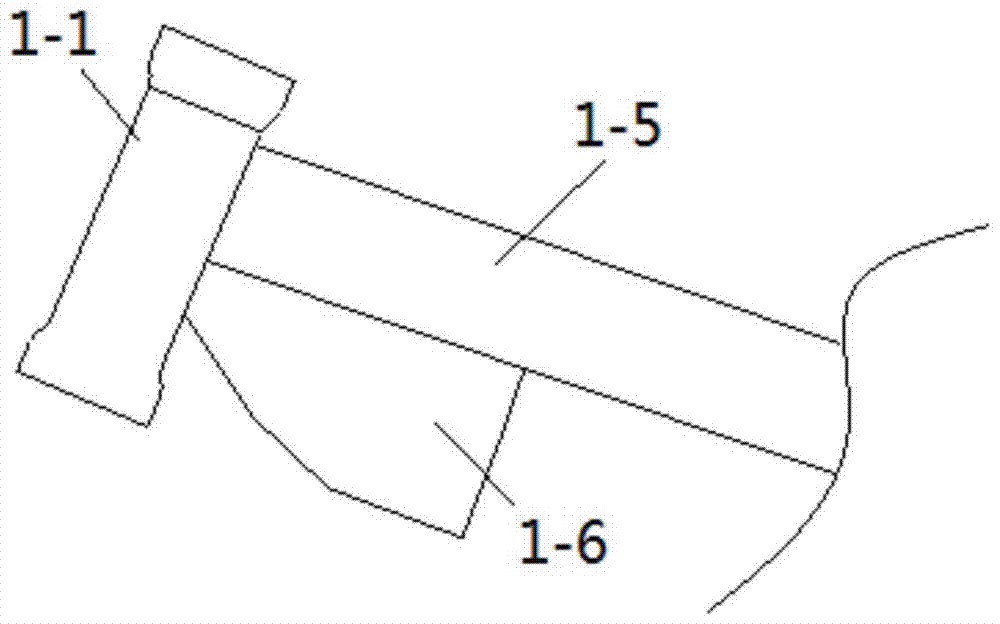

[0037] further, Figure 8 As shown, in this embodiment, on the basis of Embodiment 1, the lower end surface of the front end part of the main beam is welded with a height compensation tube 3 with a rectangular section parallel to the main beam; The lower end surface of 3 is fastened and connected by welding; one side of the first connecting piece a and the second connecting piece b are fastened and connected with the side of the main beam and / or the side of the height compensation pipe 3 by welding. In this embodiment, One side of the first connecting piece a and the second connecting piece b are fastened to the side of the main girder and the side of the height compensation pipe 3 by welding.

Embodiment 3

[0039] In this embodiment, on the basis of the above-mentioned embodiments, the triangular prism connector 1 is punched after being cut from a steel plate. The specific structure is as follows Figure 9 and Figure 10 shown.

[0040] Further, in a preferred technical solution of this embodiment, the triangular prism connector 1 includes three surfaces, and the side connecting the two bottom surfaces of the right triangular prism is the side passing through the hypotenuse of the right triangle; this technical solution is to meet the welding needs, Furthermore, the connection at the joint is made tighter, and a plane expansion suitable for the connection is made on one side of the right triangle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com