Special fixture for clamping frame artifacts

A special fixture and frame technology, applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve the problems of low qualified rate of finished products, affecting the accuracy of processing, pressure loss of frame workpieces, etc., to achieve simple structure and avoid channeling The effect of moving and improving the machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

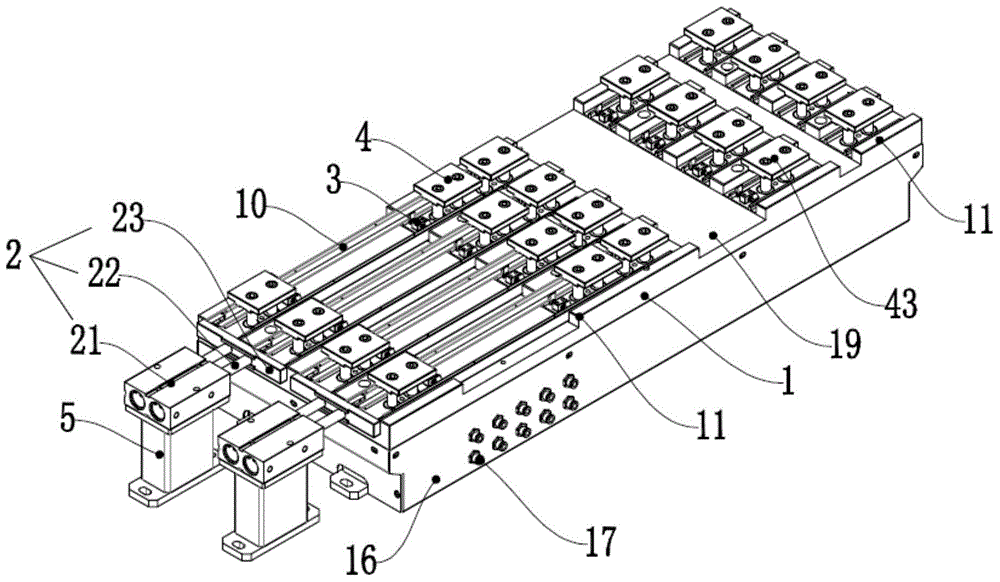

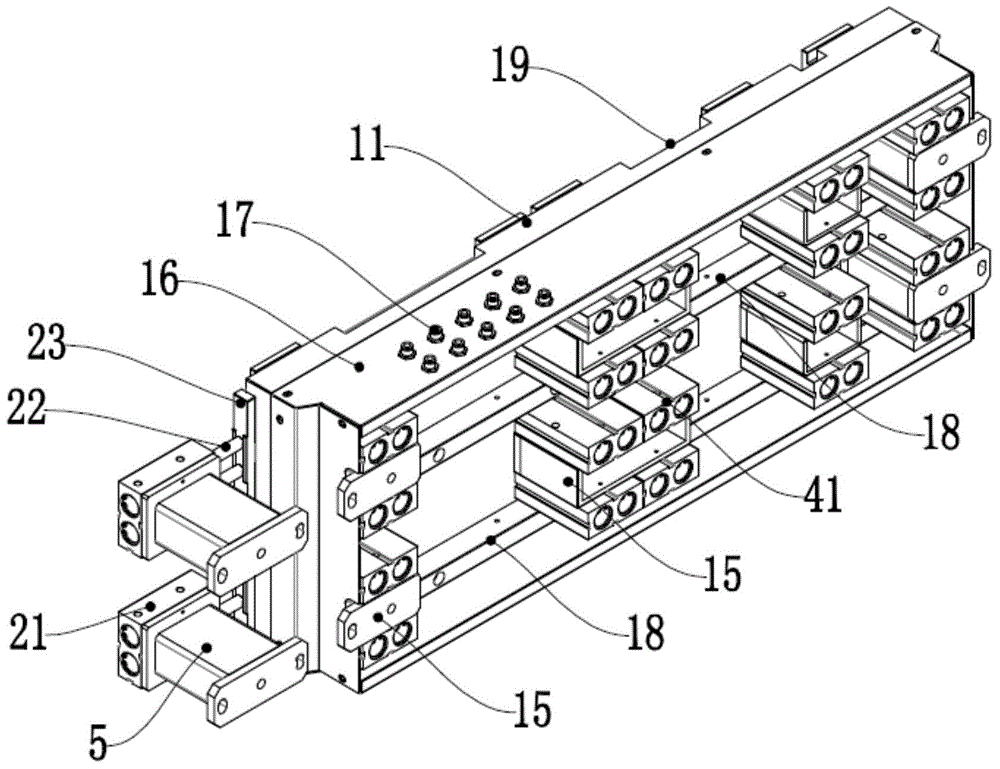

[0028] A special fixture for clamping frame workpieces, including a bottom plate 1 and a plurality of Z-direction positioning devices 4;

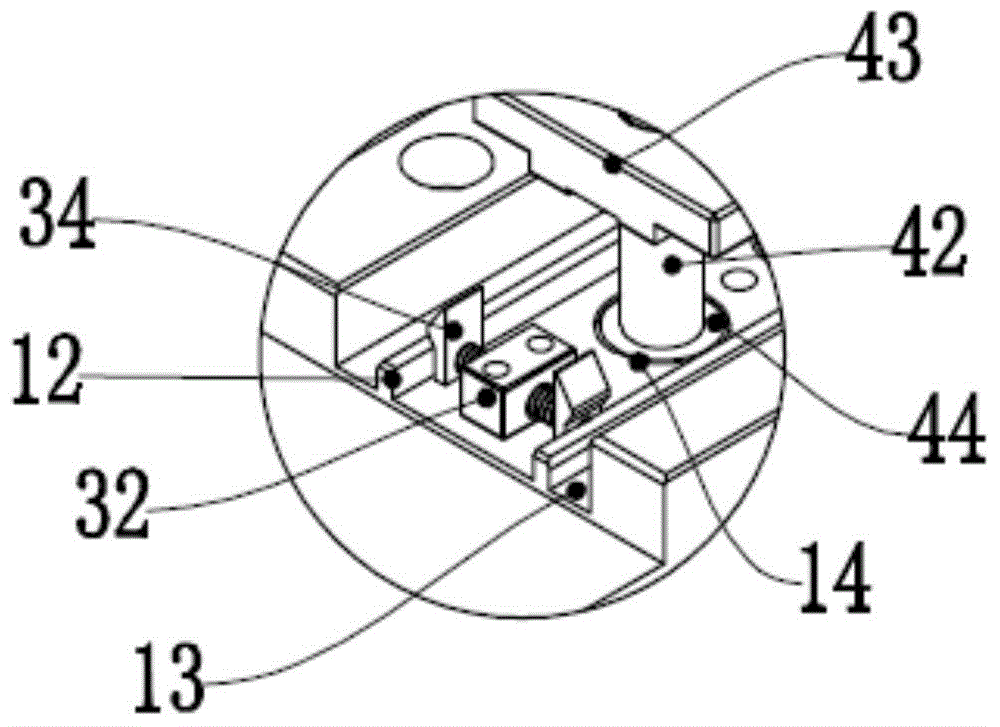

[0029] A row or more than one row of segmented clamping grooves 11 is horizontally arranged on the working table of the base plate 1, and the frame workpieces 10 are respectively placed on both sides of the grooves in the lateral direction of the clamping grooves 11. , the Z-direction positioning devices 4 are respectively arranged in the clamping groove 11 along the transverse midline position of the clamping groove 11;

[0030] The Z-direction positioning device 4 includes a Z-direction clamping cylinder 41, and the Z-direction clamping cylinder 41 is installed vertically on the bottom of the bottom plate 1 and is located below the groove surface of the clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com