Metal hammering machining tool applied to robotic arm

A processing tool and six-axis robotic arm technology, which is applied in the field of texture processing of metal materials by CNC processing tools, can solve the problems of high cost, high equipment, inflexibility, etc., and achieve the effect of low cost, simple structure, and texture processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

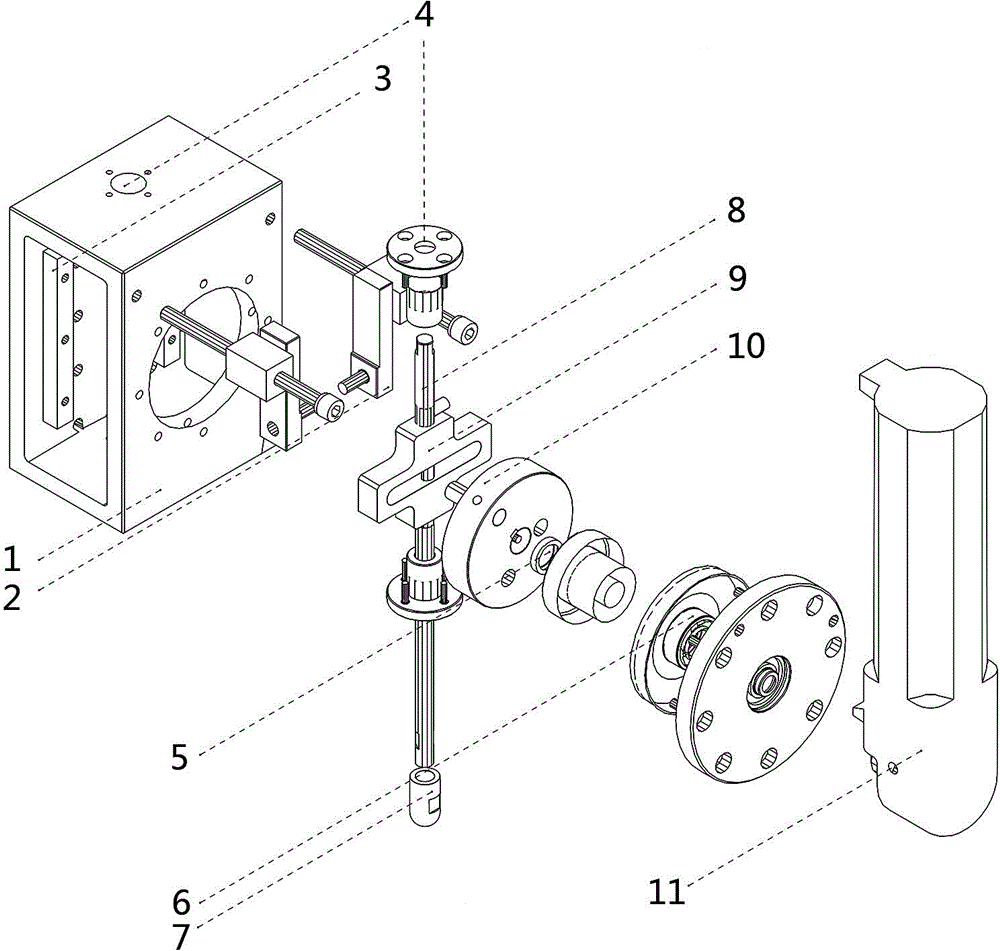

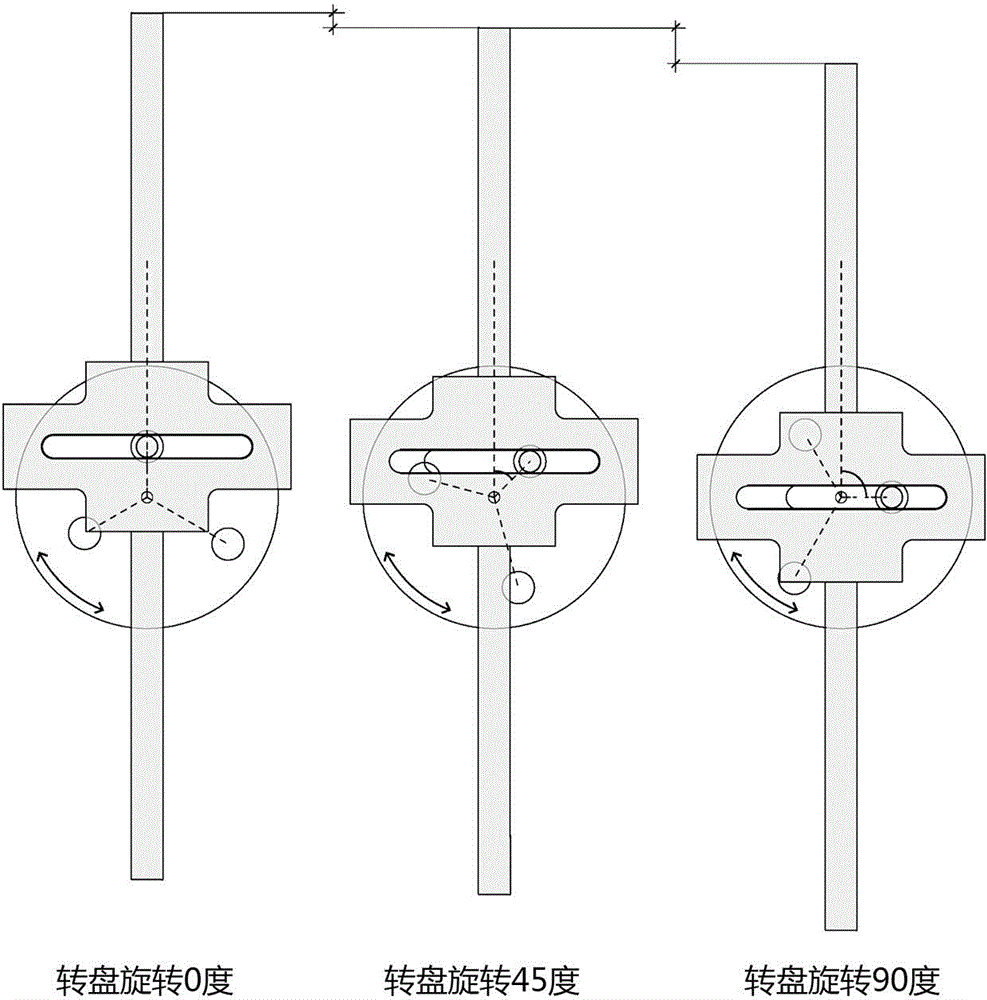

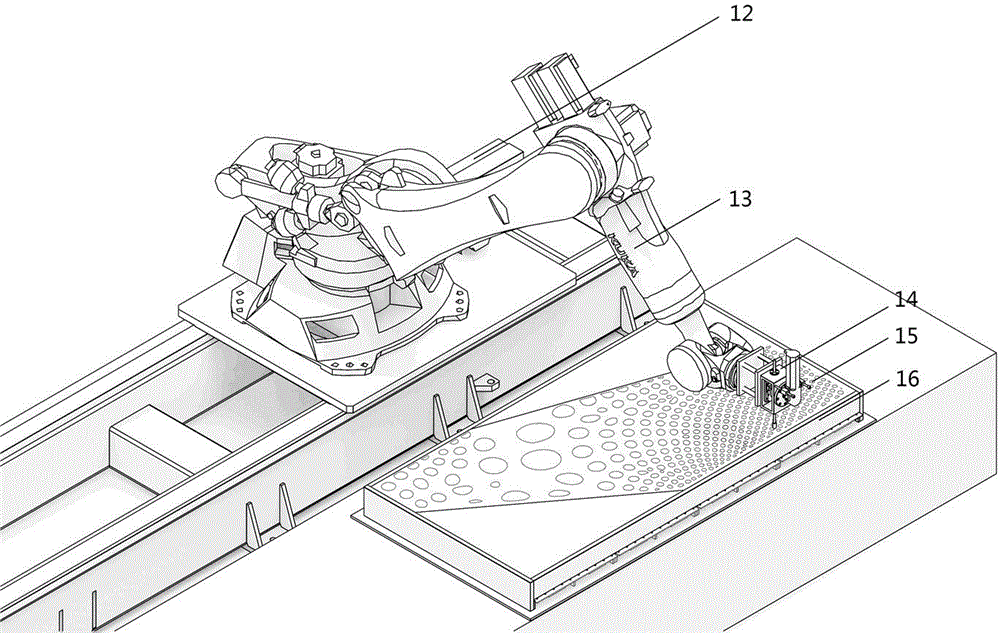

[0016] according to Figure 1-Figure 3 As shown, the present invention is composed of an aluminum alloy bracket 1, an aluminum alloy clamp 2, a hammering head and a DC motor 11. The aluminum alloy bracket 1 is custom-processed from aluminum alloy, with screw holes reserved on both sides, one side is used to connect the KUKA six-axis robotic arm 13, and the other side is used to connect the DC motor 11, and the top and bottom of the aluminum alloy bracket 1 are perforated , are respectively used to install the linear bearing 4; the inner wall of the aluminum alloy bracket 1 is close to the side of the KUKA six-axis mechanical arm, and the metal spacer 3 made of two metal blocks is used to fix the position of the Scotch yoke 9 . The aluminum alloy clamp 2 is composed of two aluminum alloy blocks, two resin pads and two silk shafts, the resin pads are worn on the wire shafts and fixed by nuts, and the wire shafts are then fixed on the aluminum alloy bracket 1 by nuts; The alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com