A precision CNC machine tool that automatically realizes parts turning around to complete their double-sided processing

A double-sided processing and precision numerical control technology, which is applied in the direction of automatic lathes/semi-automatic lathes, metal processing equipment, metal processing machinery parts, etc., can solve the problems of time-consuming and labor-intensive labor for operators, reduce the processing accuracy of parts, and increase production costs. Achieve the effects of saving process flow time, improving machining accuracy, and utilizing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

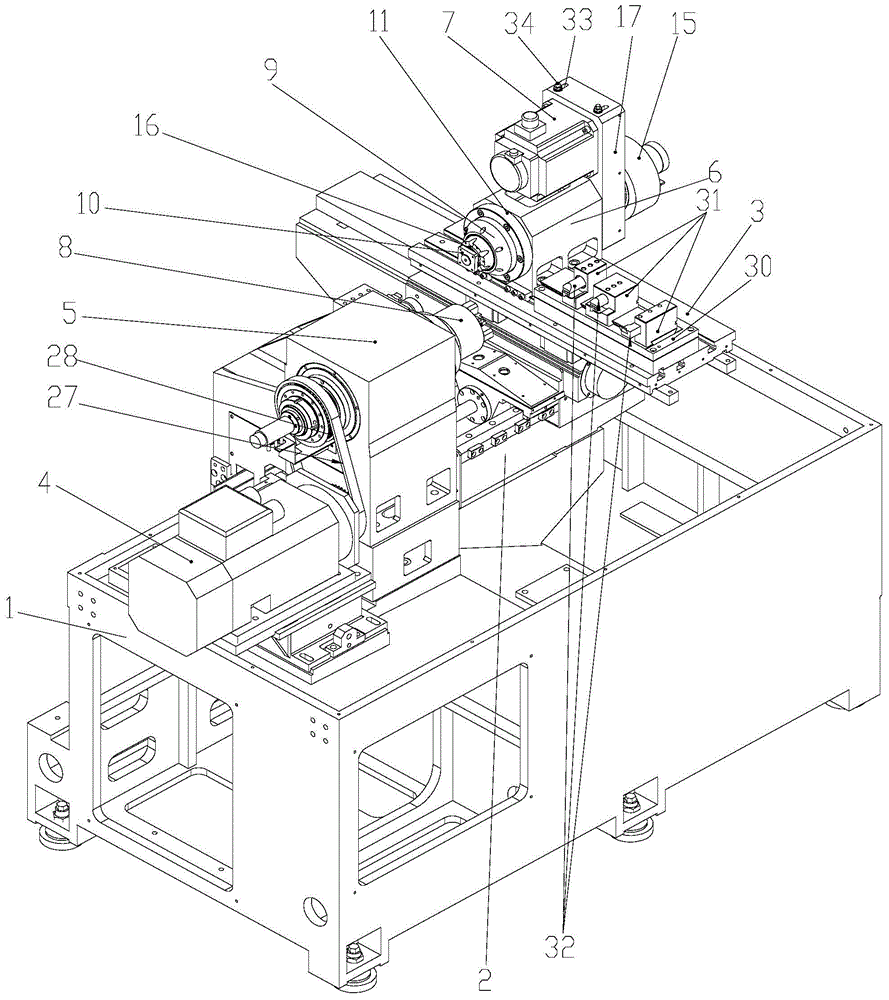

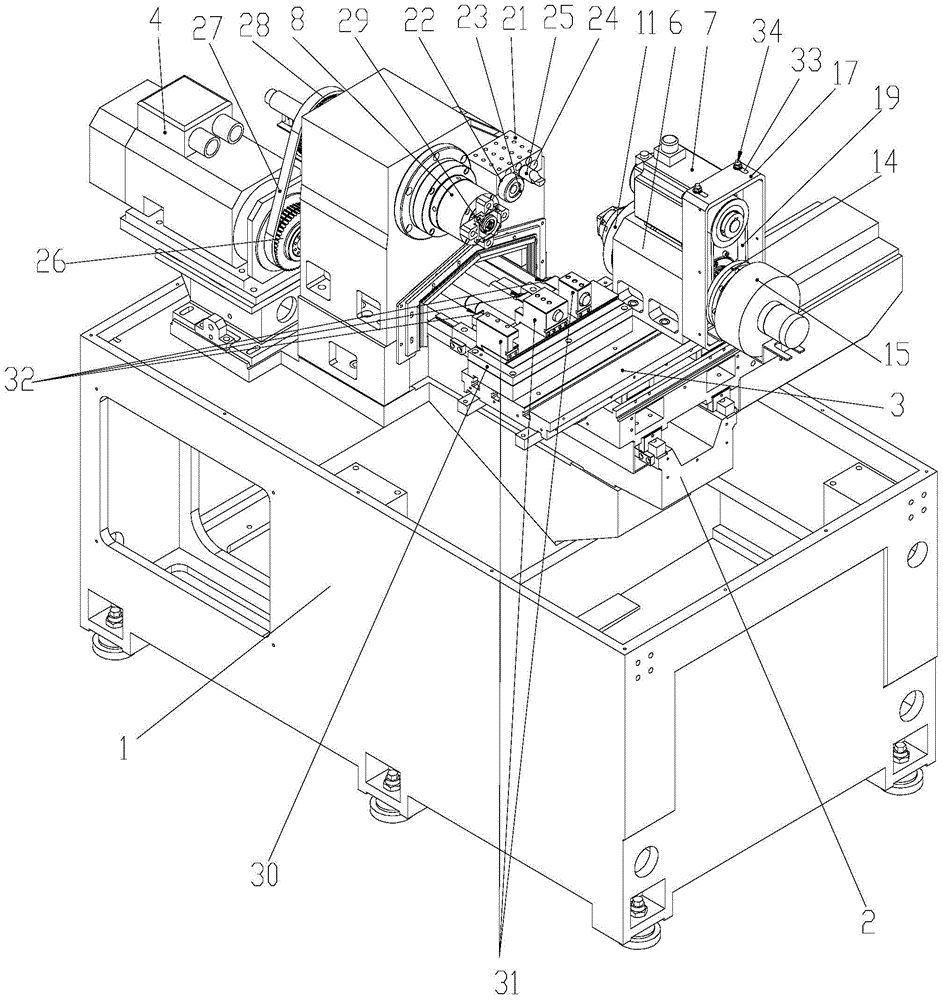

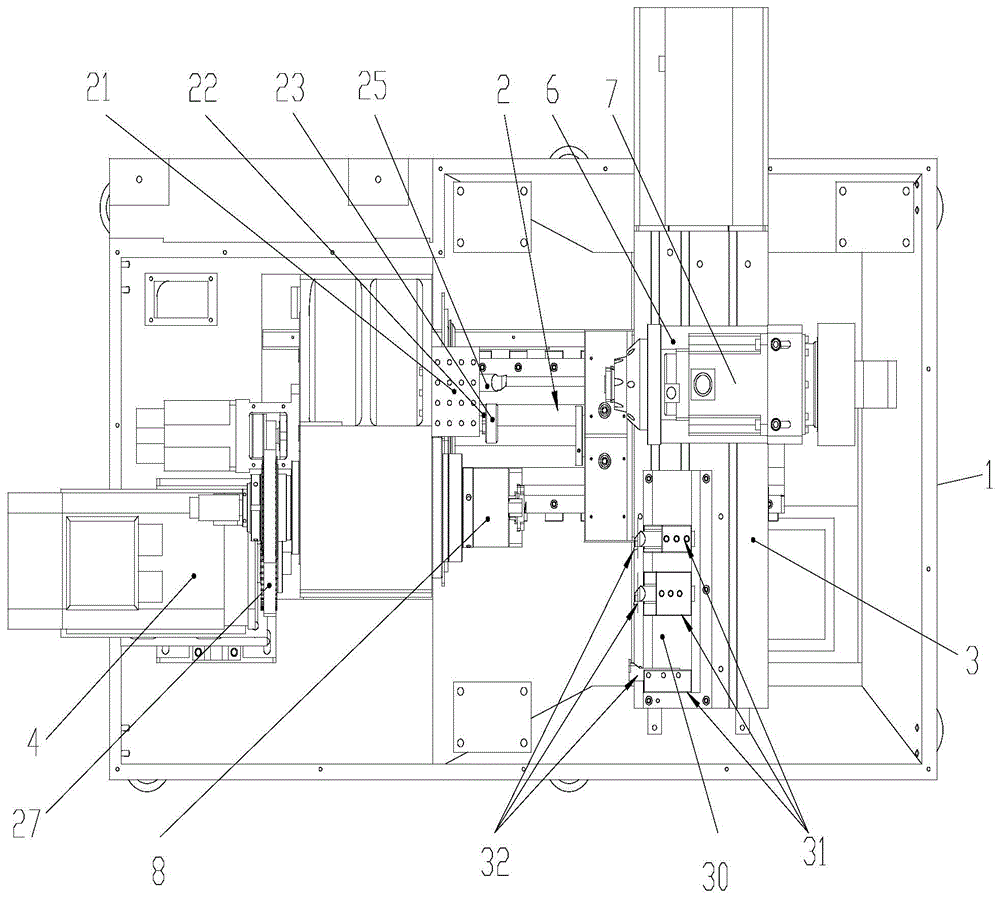

[0020] Attached below Figure 1-5 An embodiment of the present invention is described.

[0021] A precision numerical control machine tool that automatically realizes parts turning around to complete its double-sided processing has a bed 1, and a spindle system is provided on the upper side of the bed 1, and the spindle system includes a servo motor 4, a headstock 5 and a spindle 8. The main shaft 8 is supported in the main shaft box 5 through bearings. The output shaft of the servo motor 4 is provided with a main shaft driving pulley 26. The main shaft driving pulley 26 drives the main shaft passive pulley 28 arranged at one end of the main shaft 8 through the main shaft belt 27. The other end of the main shaft 8 is provided with a chuck 29 for clamping the workpiece 10; wherein, the main shaft belt 27 may preferably be a synchronous toothed belt. The other side of the upper end of the bed 1 is provided with a cross-shaped saddle 2 that slides in the Z direction. The upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com