Induction heating positioning device

A positioning device and induction heating technology, applied in induction heating and other directions, can solve problems such as affecting molding quality, high labor intensity of operators, affecting heating quality, etc., and achieve the effect of ensuring quality consistency, low production cost, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

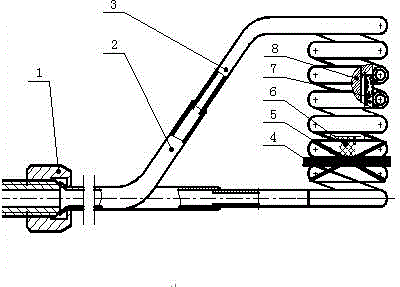

[0020] An induction heating positioning device according to the present invention, its structure mainly includes: sealing nut 1, support arm 2, induction coil 3, asbestos board 4, asbestos rope 5, adjustment block 6, quartz tube 7, blank 8, In the induction heating device of the present invention, the bending extension at the upper end of the induction coil 3 is connected to the support arm 2, and the other end of the support arm 2 is connected to the induction heating device through the sealing nut 1. The axial direction of the induction coil 3 is vertical, and at the lower end of the induction coil 3 Pad an asbestos board 4 or a non-metallic material that can withstand 1200°C, bind it with an asbestos rope 5, put the quartz tube 7 into the heating tube, and when heating the blank 8, select an appropriate adjustment block 6 according to the length of the blank 8 to It is advisable that blank 8 can be conveniently held with tweezers after putting into blank 8 . The outer diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com