Energy-saving conveniently controlled motor control circuit

A technology for controlling circuits and motors, applied in the direction of AC motor control, control systems, electrical components, etc., can solve the problems of unbalanced vibration faults, insufficient control, insufficient energy saving, etc., and achieve low cost, convenient and safe control, convenient control and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

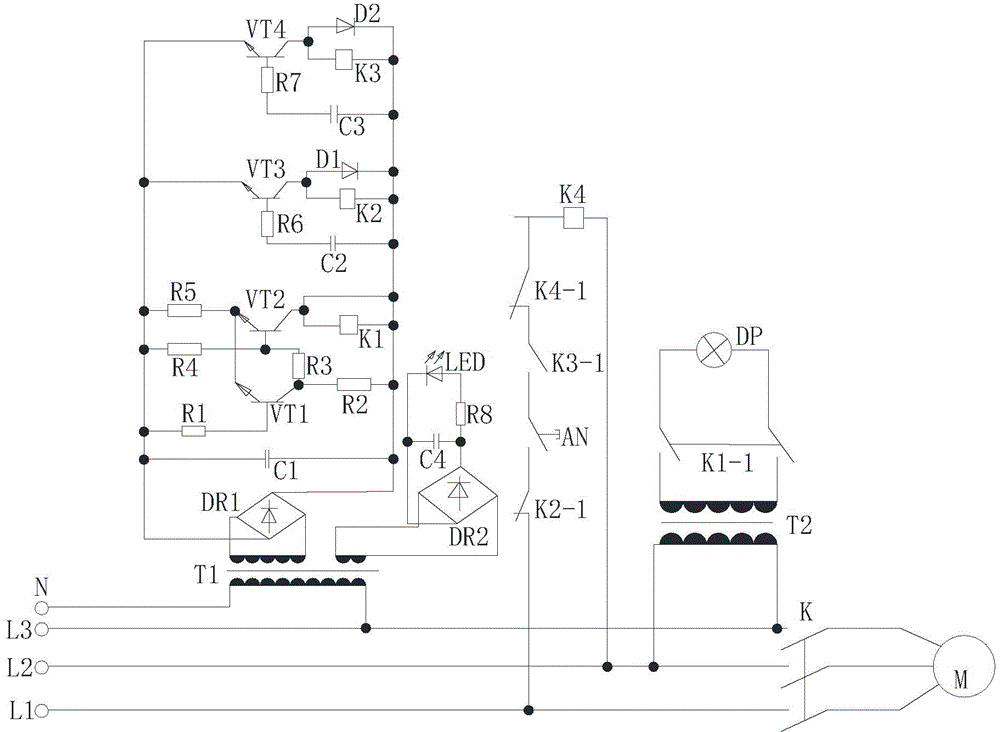

[0010] like figure 1 Shown: the present invention includes a first transformer T1, a second transformer T2, a triple switch K, a button switch AN, a first resistor R1 to a seventh resistor R7, a first relay K1 to a fourth relay K4, a first capacitor C1 to a second capacitor Four capacitors C4, the first triode VT1 to the fourth triode VT4, the first diode D1, the second diode D2, the light emitting diode LED, the first rectifier DR1, the second rectifier DR2 and the bulb DP, textile The three terminals of the motor M of the machine are connected to the three terminals of the three-phase power supply through the triple switch K, and the two ends of the primary side of the second transformer T2 are respectively connected to the second terminal L2 and the third terminal L3 of the three-phase power supply, and the second transformer T2 The two ends of the stage are connected i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com