Structure for measuring iron loss of motor stator core

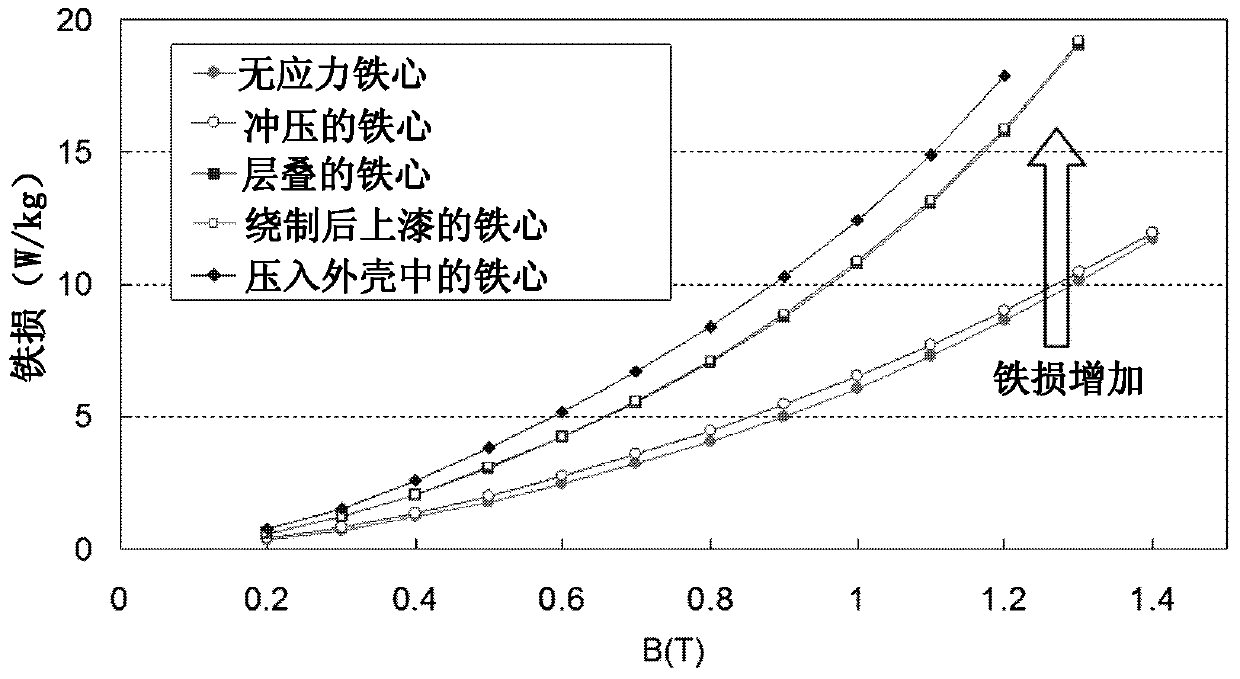

A motor stator and stator core technology, applied in the direction of measuring electrical variables, measuring current/voltage, measuring devices, etc., can solve the problems of measurement accuracy reduction, measurement magnetic field strength error, etc., to improve measurement accuracy, improve efficiency, and reduce iron loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

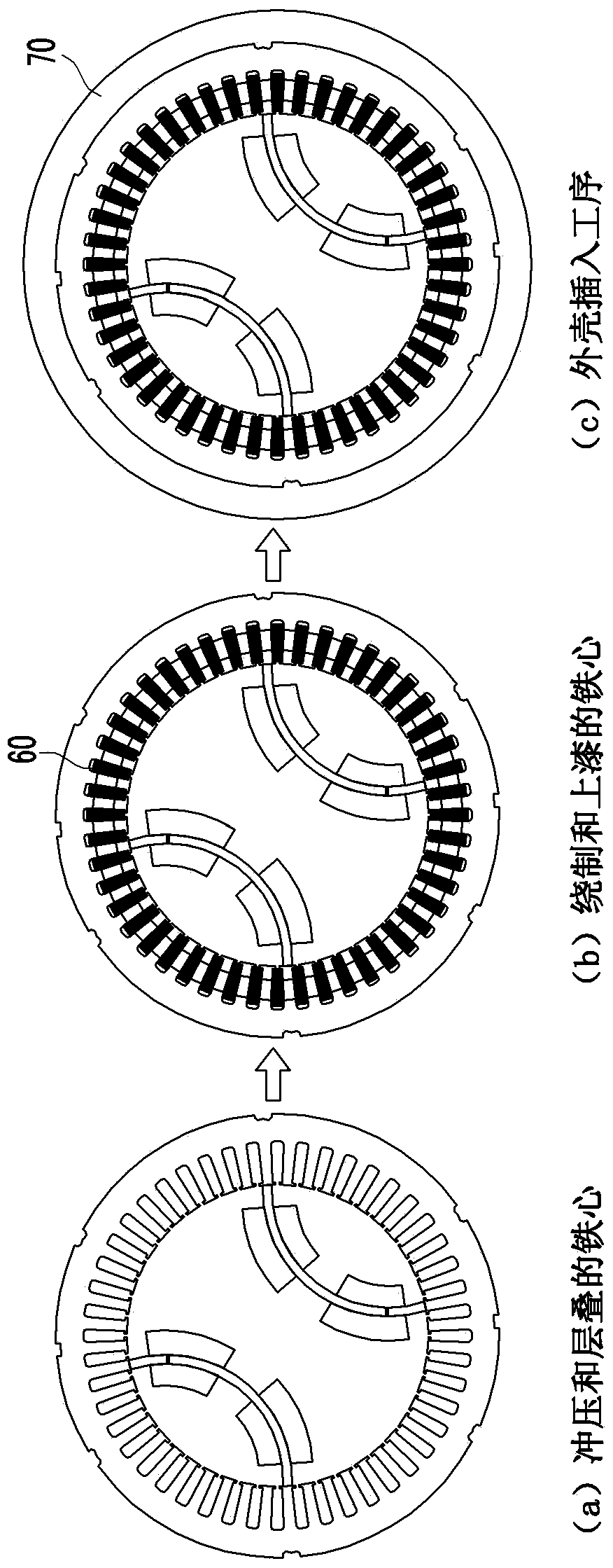

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, the present invention will be described more fully with reference to the accompanying drawings so that those skilled in the art can implement exemplary embodiments of the invention.

[0053] refer to Figure 7 , the structure for measuring iron loss of a motor stator core according to an exemplary embodiment of the present disclosure may include a C-shaped auxiliary core 100 substantially in the shape of a letter 'C'. The C-shaped auxiliary core 100 may have a substantially uniform width in the longitudinal direction. The fixing protrusions 102 may protrude from both end surfaces of the C-shaped auxiliary core 100 in the longitudinal direction and extend longitudinally. The fixing protrusion 102 may protrude from the centers of both end surfaces of the C-shaped auxiliary core 100 in the width direction. The fixing protrusion 102 has a square shape, but may have other shapes as long as it is inserted and fixed in a slot between stator teeth described below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com