Transformer substation outer shell with fireproof electromagnetic shielding plastic

An electromagnetic shielding and substation technology, applied in the field of substations, can solve the problems of easy corrosion and rust, heat dissipation and flammability, and metal shell conduction, and achieve good electromagnetic shielding effect, excellent combustion resistance, and enhanced connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific diagrams.

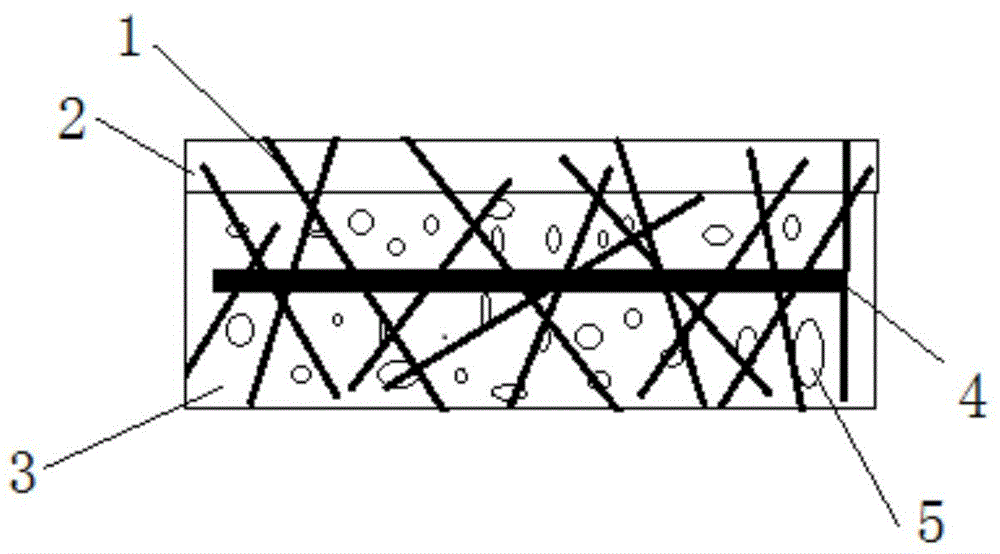

[0032] refer to figure 1 , the substation shell using fireproof electromagnetic shielding plastics, including a plastic matrix 3, embedded in the plastic matrix 3 is a conductive fiber layer 4, the conductive fiber layer 4 is a fiber layer made of conductive fibers, and embedded in the plastic matrix 3 is a particle size ≤ 3mm perlite particles 5, a refractory mica layer 2 is provided on the outside of the plastic matrix 3; the substation shell using fireproof electromagnetic shielding plastics also includes a three-dimensional network structure 1 made of mineral ropes, and the three-dimensional network structure 1 runs through the Plastic base 3 and refractory mica sheet 2. The conductive fiber layer 4 of the present invention constitutes an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com