Falling prevention structure of panel type wiring terminal strip

A technology of terminal block and anti-drop structure, which is applied in the direction of connection, conductive connection, electrical components, etc., can solve the problems of poor wire locking, easy wiring and wrong wiring efficiency, etc., so as to ensure the wiring accuracy and improve the wiring efficiency. , to avoid the effect of short circuit electric shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

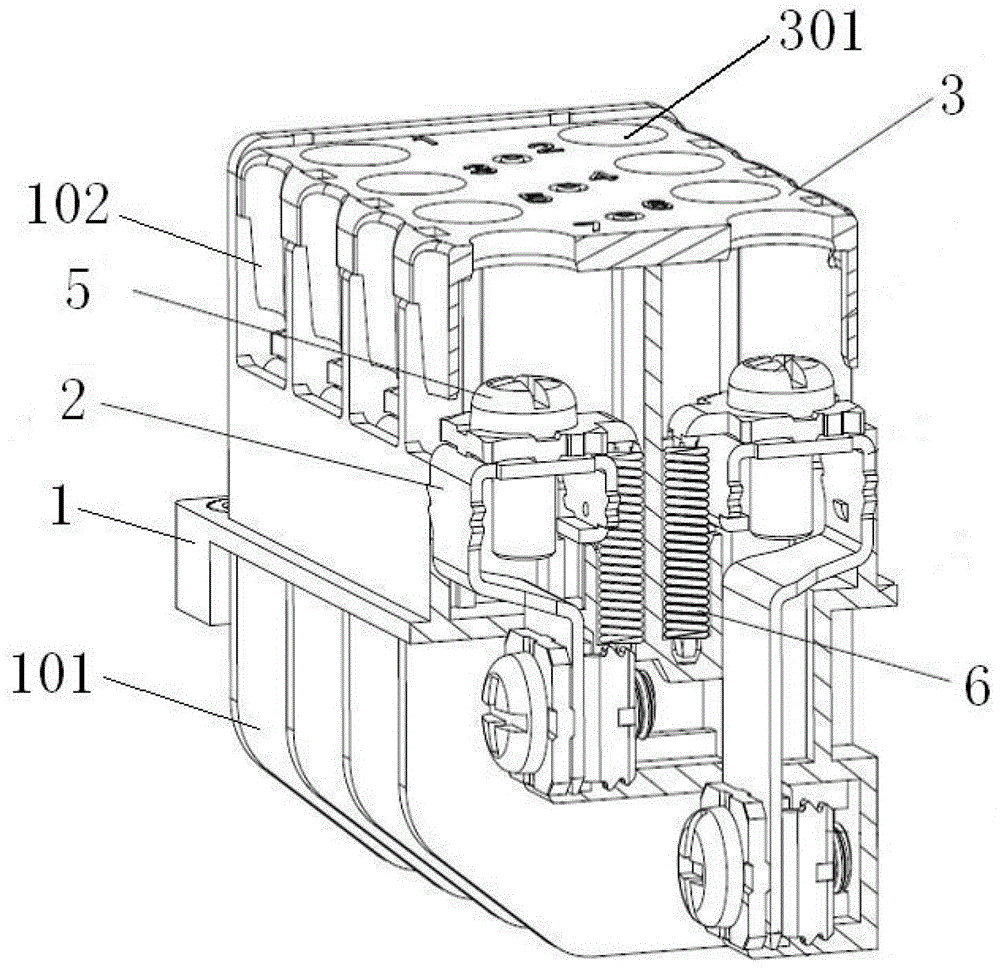

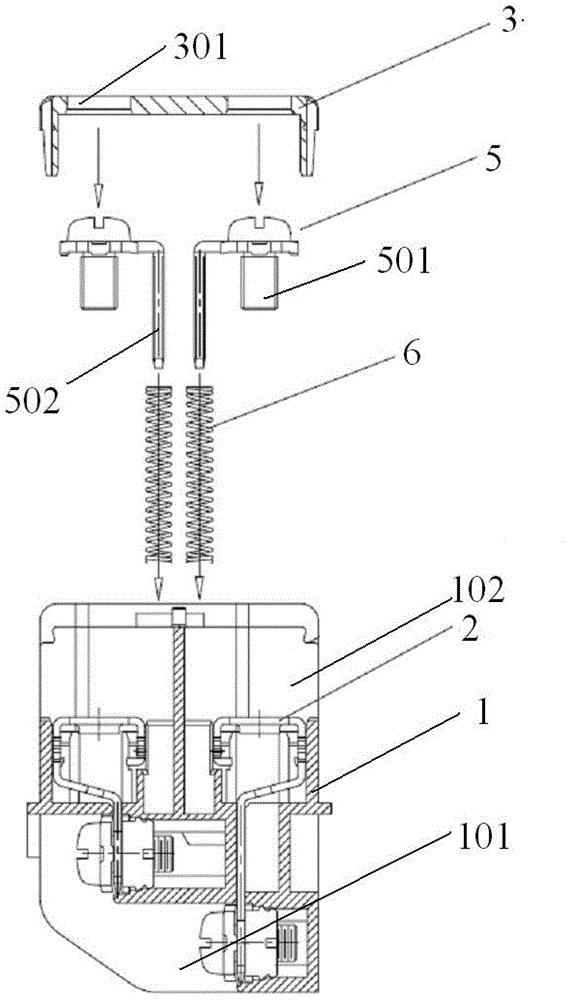

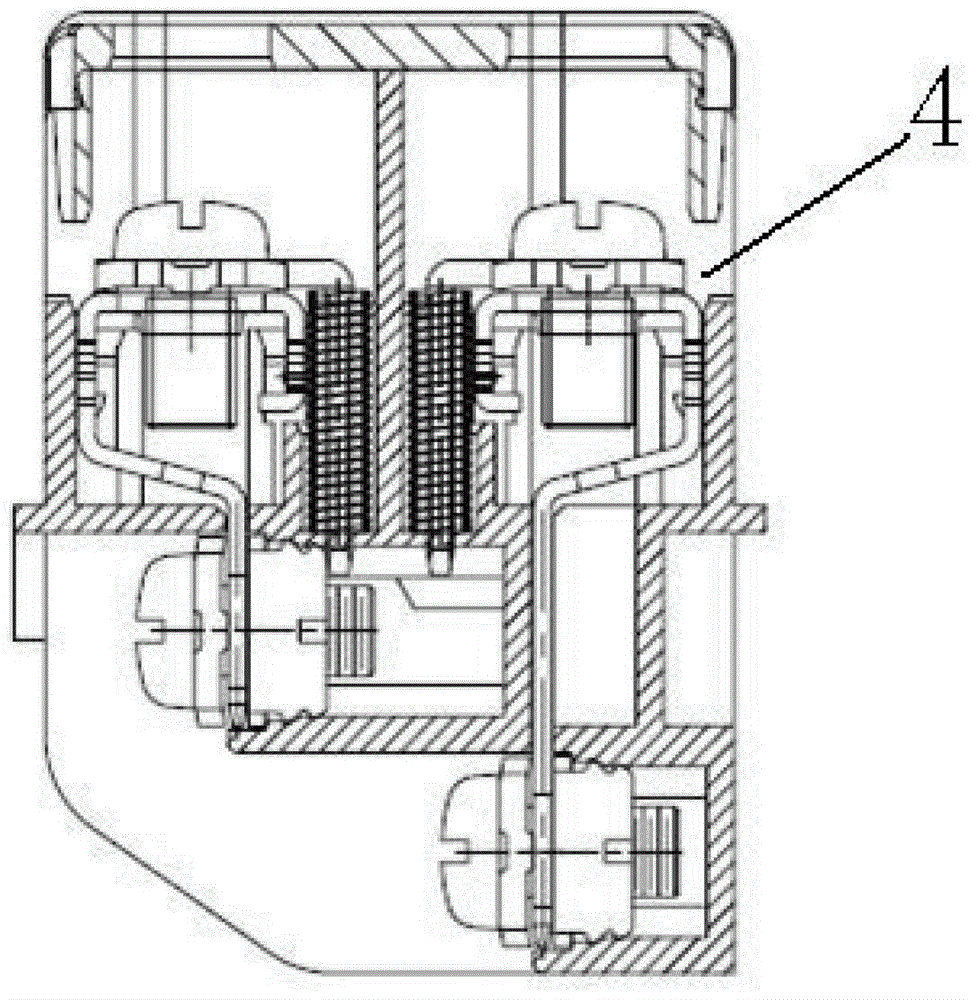

[0025] combine Figure 1 to Figure 6 The present invention is described in further detail.

[0026] An anti-detachment structure for a panel-type terminal block, comprising an insulated terminal block body 1, on which at least one internal connection groove 101 and at least one external connection groove 102 arranged opposite to each other are opened, wherein the external connection The slots 102 are arranged in two rows facing upwards and are mirror-symmetrical. The inner wiring slots 101 and the outer wiring slots 102 are arranged opposite to each other and the openings are facing downwards.

[0027] Each pair of inner and outer wiring grooves 101 and 102 disposed opposite to each other is positioned with a conductive sheet 2 pierced therein, and the conductive sheet 2 can be set in a shape that is easy to communicate with wires of other equipment. In this embodiment, the conductive sheet 2 is set as a hook-shaped structure with a handle. The lower end of the conductive she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com