Pull ring for bus

A technology for buses and pull rings, which is applied to vehicle parts, special positions of vehicles, transportation and packaging, etc. It can solve problems such as easy to miss cleaning dead corners, incomplete disinfection, and difficulty in removing pull rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

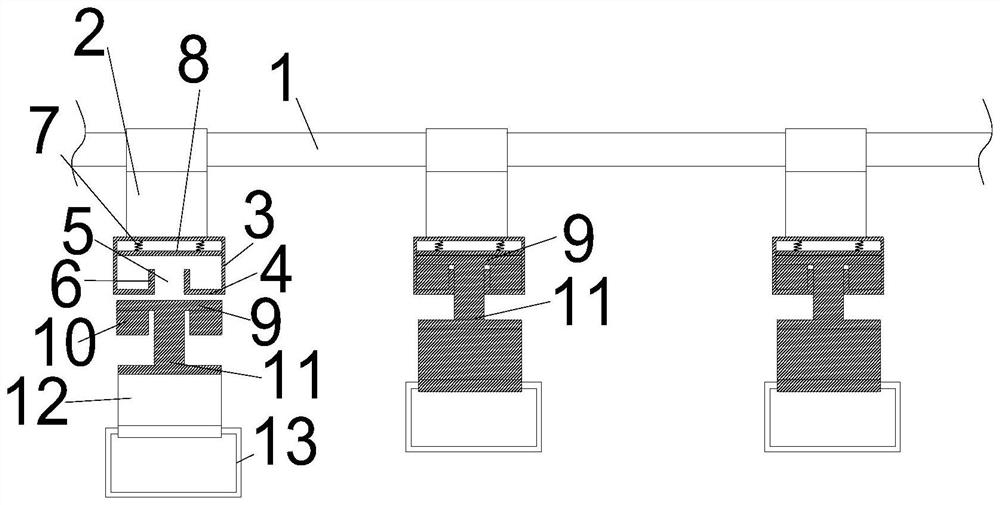

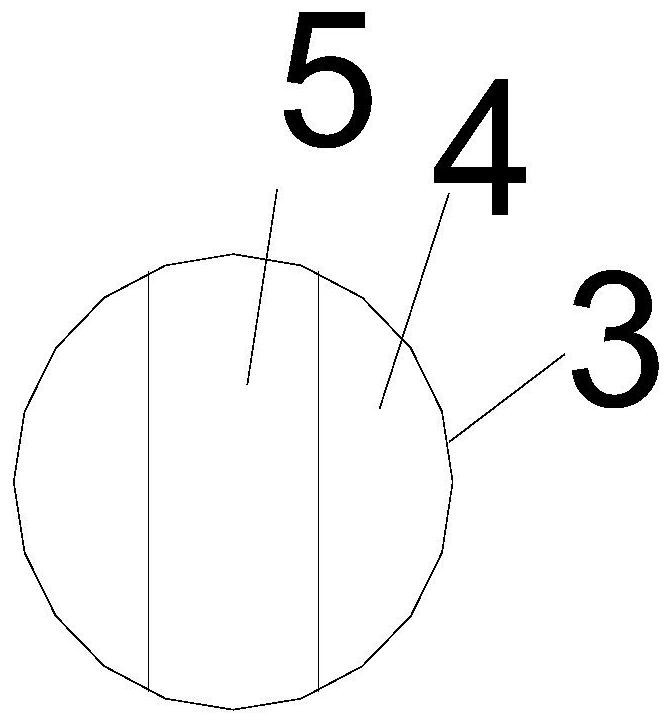

[0017] Such as Figure 1-2 The shown pull ring for a bus includes a plurality of first fixing straps 2 fixed on a transverse fixing rod 1. The bottom of the first fixing strap 2 is fixed with a cylindrical card shell 3, and the bottom of the card shell 3 is convexly formed with two Opposite to the cover plate 4, an insertion seam 5 is formed between the two cover plates 4, and the cover plate 4 is fixed with a card plate 6 inside the card housing 3; the top of the card housing 3 is connected with a top plate 8 through an elastic structure 7; A cross bar 9 is installed in the seam 5, the two ends of the cross bar 9 are protrudingly formed with clamp blocks 10 that are matched with the clamping plate 6, the middle of the cross bar 9 is connected with a T-shaped bar 11, and the T-shaped bar 11 is connected with a second fixing belt 12. The second fixing band 12 is connected to the pull ring body 13.

[0018] The elastic structure 7 is a spring.

[0019] The first fixing band 2 is em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com