LED epitaxial structure and method achieving high luminous energy density output

An epitaxial structure and density technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as sacrificing efficiency and increasing driving current, achieving good flexibility, high energy conversion efficiency, and improving optical control factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

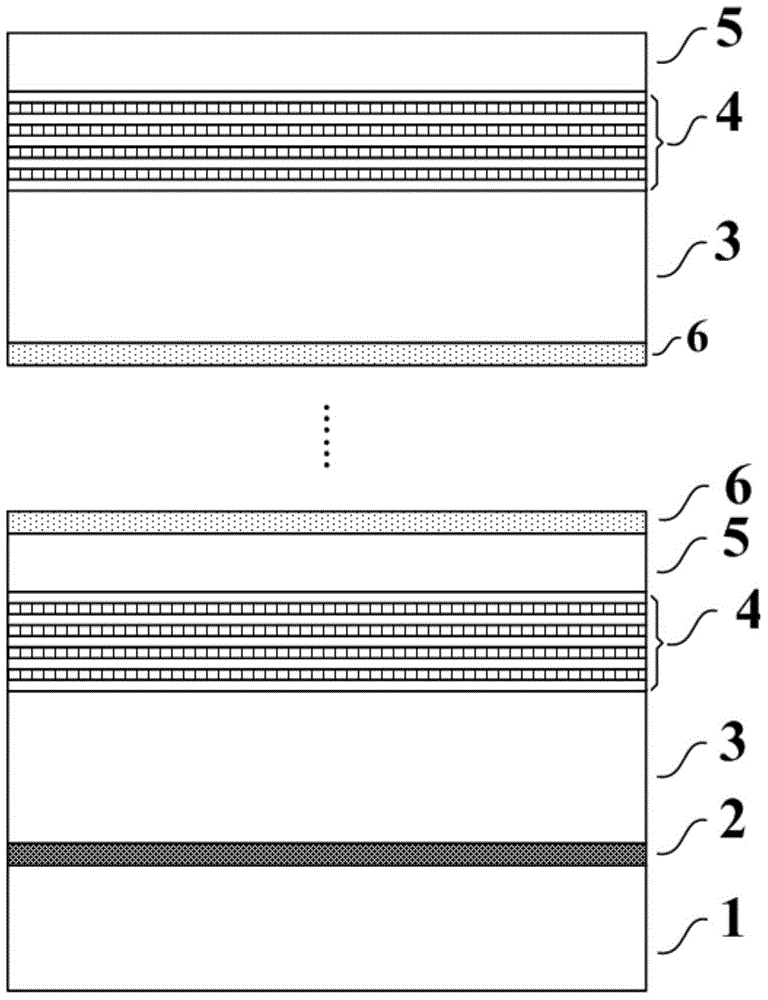

[0047] Such as figure 1 As shown, it is a schematic cross-sectional view of an LED epitaxial structure with high luminous energy density output according to Embodiment 1 of the present invention, including a substrate layer 1, a buffer layer 2, a tunnel node 6 and two groups of LED basic structural units arranged in sequence; The first group of LED basic structural units are respectively composed of n-type layer 3, p-type layer 5 and light-emitting layer 4, the light-emitting layer 4 is located between n-type layer 3 and p-type layer 5; the second group of LED basic structural units are respectively composed of The n-type layer 3 , the p-type layer 5 and the light-emitting layer 4 are formed, and the light-emitting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com