Gas supply device and method for cooling static sucker

A technology of electrostatic chuck and gas supply device, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc. It can solve problems such as leakage, changes in reaction conditions, inconsistent effects between the center and edge areas of the substrate 30, and achieve good temperature distribution. Effect, small fluctuation, effect of ensuring heat transfer and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

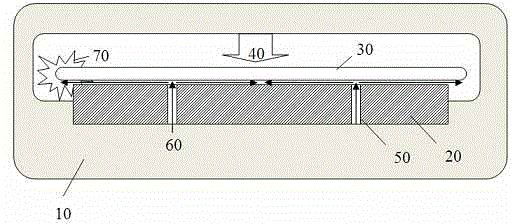

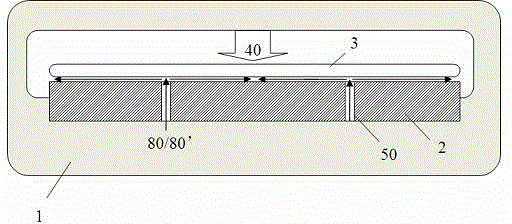

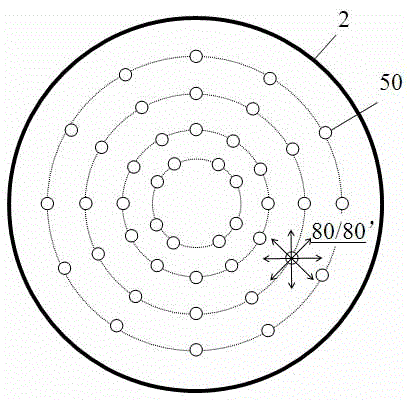

[0040] like figure 2 , Figure 4As shown, the bottom of the vacuum processing chamber 1 is provided with an electrostatic chuck 2 with a diameter equal to or greater than that of the substrate 3 for fixing and supporting the substrate 3 placed thereon. The first process gas 40 is introduced into the vacuum processing chamber 1 from above to perform etching or other processing on the surface of the substrate 3 . One path of second process gas 80 or 80' replaces or partially replaces helium as cooling gas, and transports it to the gap between the back surface of the substrate 3 and the top surface of the electrostatic chuck 2 through the corresponding gas channel opened in the electrostatic chuck 2, and Sheet 3 undergoes heat transfer cooling. Use a gas with the same or very close composition as the first process gas 40 as the second process gas 80 or 80', thereby effectively avoiding the problem of changing the reaction conditions at the edge of the substrate 3 due to the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com