Automatic arrangement and linkage design method of unit rail section of railway seamless line

A technology of seamless lines and design methods, applied in computing, special data processing applications, instruments, etc., can solve problems such as inability to rearrange unit rail sections, prone to errors, and restrict work efficiency, so as to improve design efficiency and The quality of the results, the obvious promotion and application value, and the effect of improving the design means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

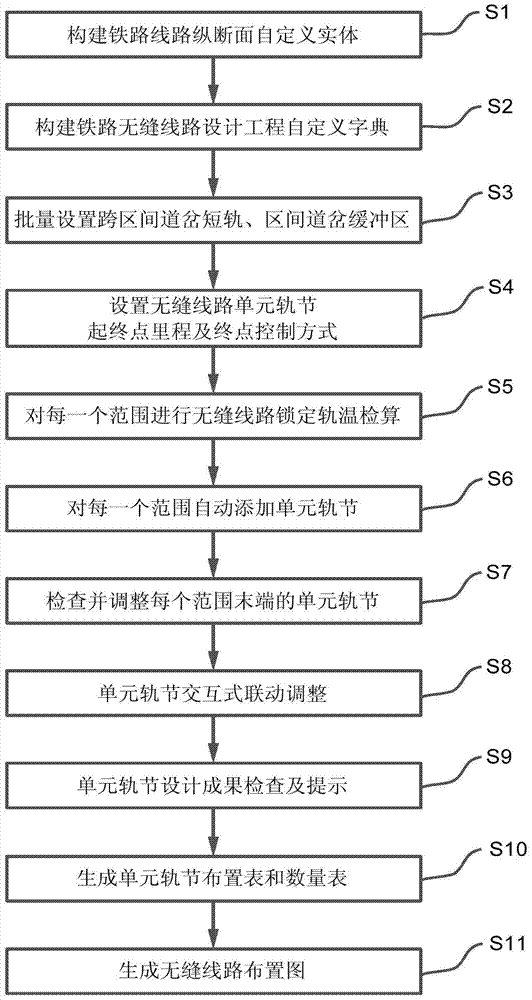

[0032] The specific technical solutions of the present invention are described with reference to the accompanying drawings. Depend on figure 1 As shown in the flow chart of the present invention, the steps of the automatic layout and linkage design method for railway seamless track unit rail sections include: constructing a self-defined entity for the longitudinal section of a railway line, constructing a custom dictionary for railway seamless line design engineering, batch Set the short track of the cross-section turnout and the buffer zone of the section turnout to form multiple ranges for the unit rail section design, set the starting and ending mileage and end point control mode of the seamless line unit rail section, and lock the track temperature for each range Check calculation, automatically add unit rail sections for each range, check and adjust unit rail sections at the end of each range, interactive linkage adjustment of unit rail sections, check and prompt unit rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com