Filter-dryer

A filter dryer and filter technology, applied in the direction of progressive dryers, dryers, drying gas arrangement, etc., can solve the problems of increased risk of material pollution, difficulty in guaranteeing material recovery rate, inconvenient operation, etc., and achieve saving Human, material and equipment investment, reducing the risk of pollution, and reducing the effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

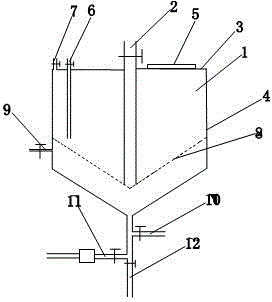

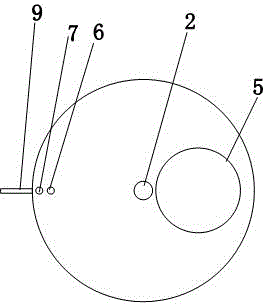

[0018] As shown in the figure, a filter dryer described in this embodiment includes a body 1 and a suction pipe 2, the body 1 includes a body cover 3 and a body 4; the bottom of the suction pipe 2 is V-shaped, and is connected to the support frame There is a certain gap between them. The body cover 3 includes a manhole 5, a feed pipe 6 and an exhaust pipe 7; The bottom of the fuselage 4 and the support frame 8 are V-shaped and parallel to each other. A drain valve is installed on the drain pipe 11 .

[0019] Lay a suitable filter cloth on the support frame 8 and fix it, then open the feeding valve of the feeding pipe 6, enter the material through the feeding pipe 6, close the pumping pipe 2, feeding pipe 6, exhaust after feeding the material Pipe 7, steam pipe 9, the valve of the emptying pipe 12 and the drain pipe 11, open the valve of the vacuum pipe 10 and start vacuuming, the water in the material will be sucked out through the filter cloth, so as to realize the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com