Double-air-inlet range hood and control method thereof

A range hood and air inlet technology is applied in the field of kitchen appliances, which can solve the problems that the air inlets cannot be isolated from each other, the suction force is not maximum, and cannot be coordinated, and achieves the effects of simple structure, convenient processing and assembly, and reasonable shape and installation structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described:

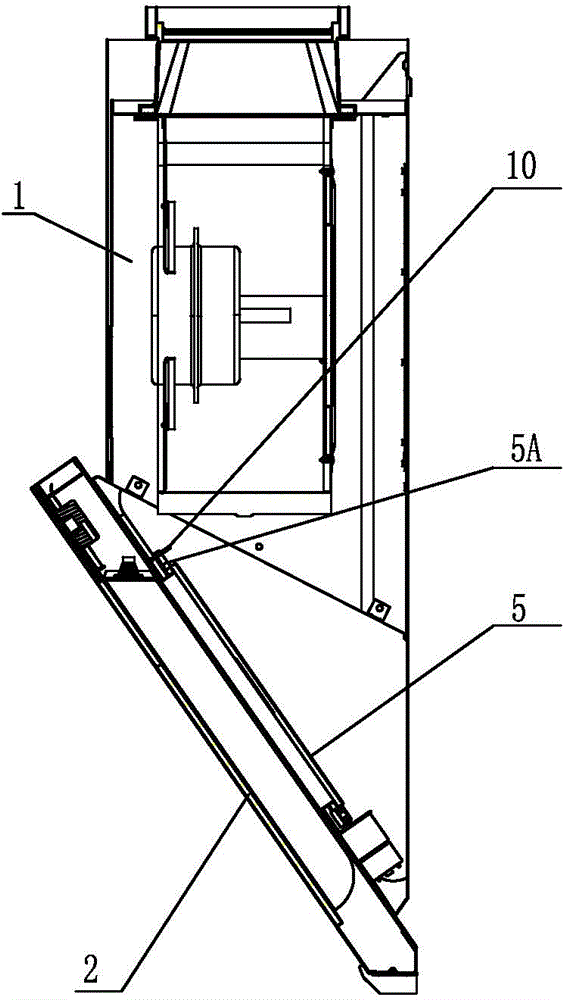

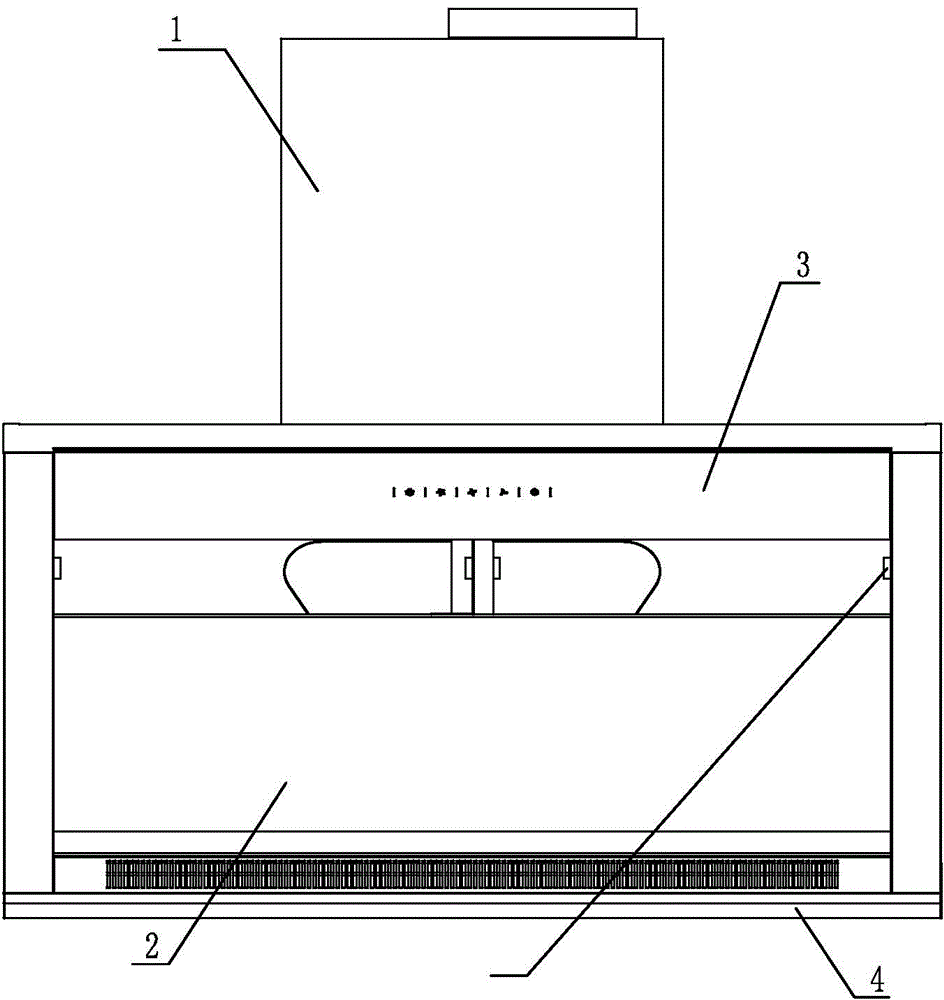

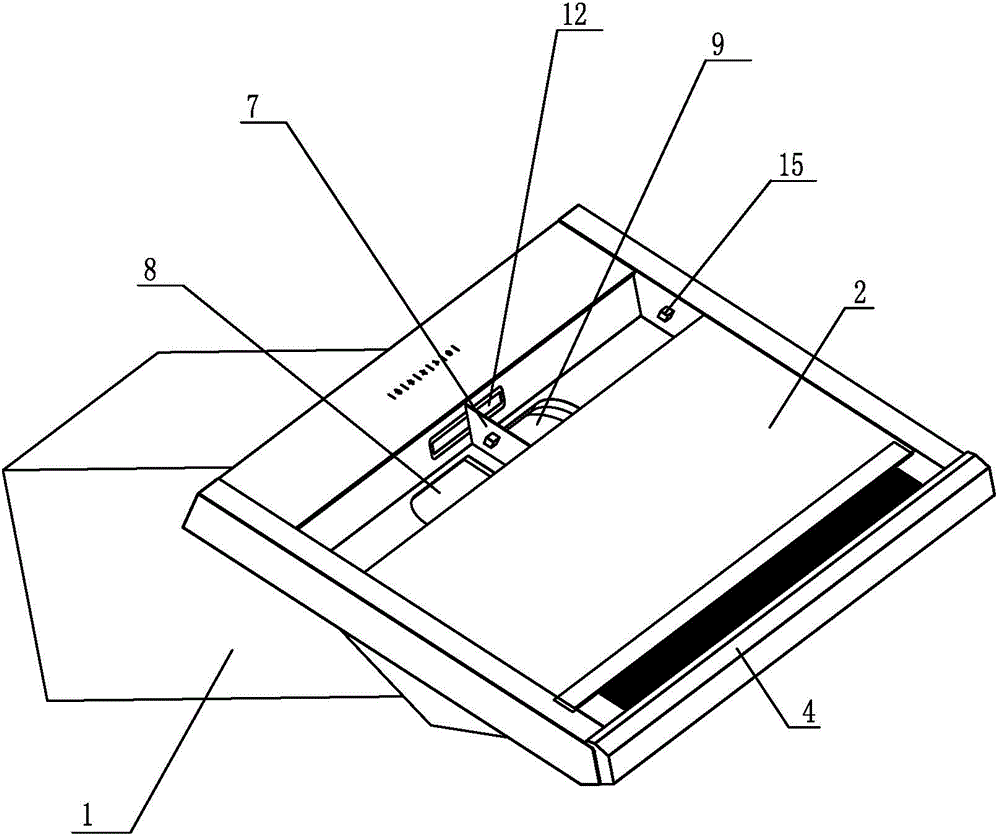

[0025] Refer to attached Figure 1 to Figure 6 As shown, the range hood with double air inlets of the present invention includes a box body 1, an air deflector 2 and a switch panel 3, the inside of the air deflector 2 has a smoke collection chamber 11, and there is a space between the switch panel 3 and the air deflector 2 The smoke collecting cavity communicates with the outside. The bottom plate of the smoke collecting cavity is provided with symmetrically arranged left air inlets 8 and right air inlets 9. A separating plate 7 extending from the air deflector to the bottom plate of the smoke collecting cavity is arranged between the two air inlets. The back of the bottom plate of the smoke collecting cavity is hinged with an air inlet sealing plate 5, which is adapted to the shape of the left air inlet 8 and the right air inlet 9, and the air inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com