Sealing Mechanism And Sealing Method

A sealing mechanism and sealing technology, applied in chemical instruments and methods, separation methods, engine sealing, etc., can solve problems such as processing tolerances, and achieve the effect of reducing installation burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

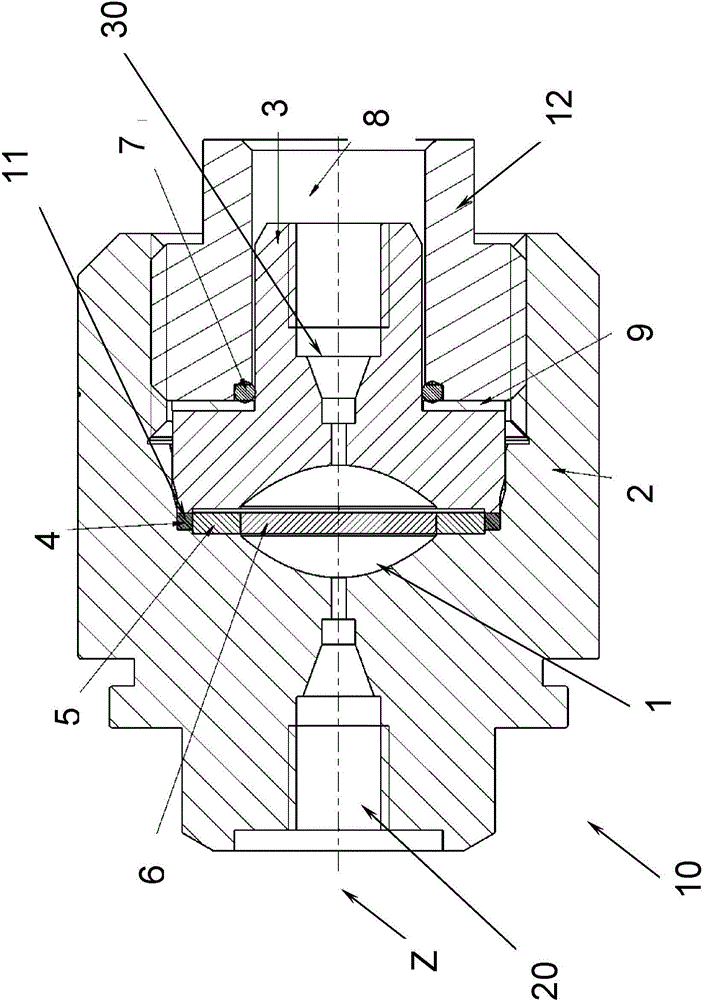

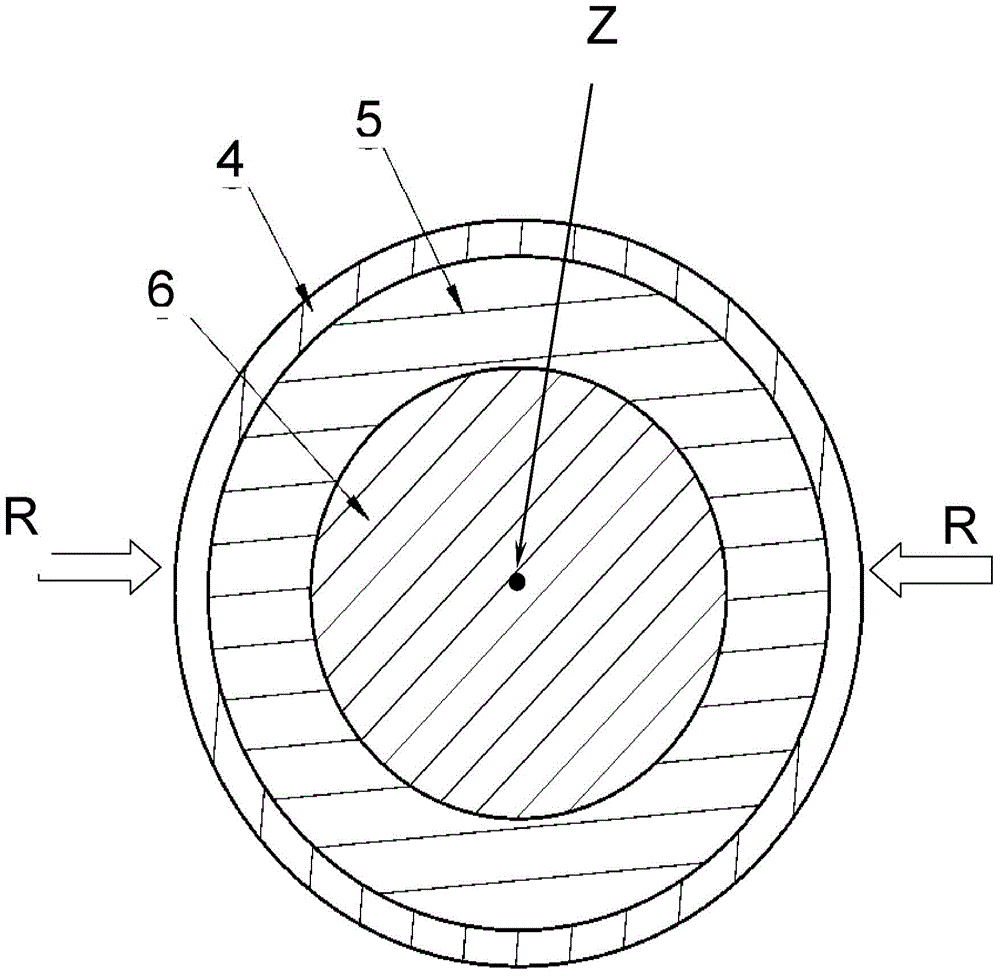

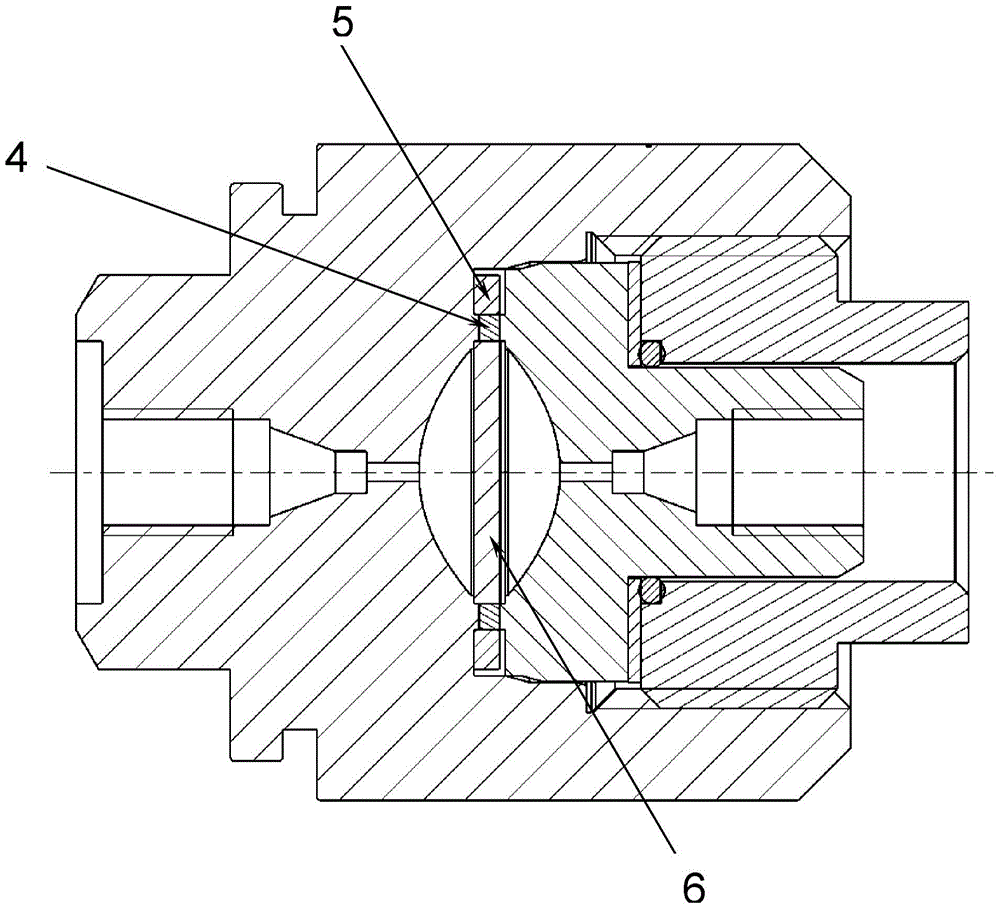

[0022] figure 1 A connection from HPLC technology is shown, which allows the accommodation of a replaceable frit 6 and is designed for working pressures above 100 MPa. The illustrated sealing device 10 comprises a housing 2 which is substantially rotationally symmetrical about the Z-axis. The pressing member 3 can enter the housing through the open end of the housing 2 along the Z axis. The screw-in part 12, which applies force to the pressing part 3 from the rear side, can be screwed into the housing 2 along the Z direction for this purpose, whereby the pressing part 3 can be inserted into the housing 2 (in the figure 1 from right to left) or firmly clamped in it. The housing 2 or the pressing part 3 has communicating channels 20 or 30 , from which a medium can be introduced under high pressure into the interior 1 formed by the housing 2 or the pressing part 3 or can be discharged. The medium is now guided through the disk-shaped frit 6 arranged coaxially to the Z-axis in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com