Eyelet

A technology for corns and eye buttons, applied in the field of eyelets, can solve the problems of inferior use, falling off of eyelets, not fully eliminating fabric breakage, etc., to achieve the effects of weight reduction, installation burden reduction, and product unit price reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below, refer to Figure 1 to Figure 5 The one-piece type eyelet of the present invention will be described in detail.

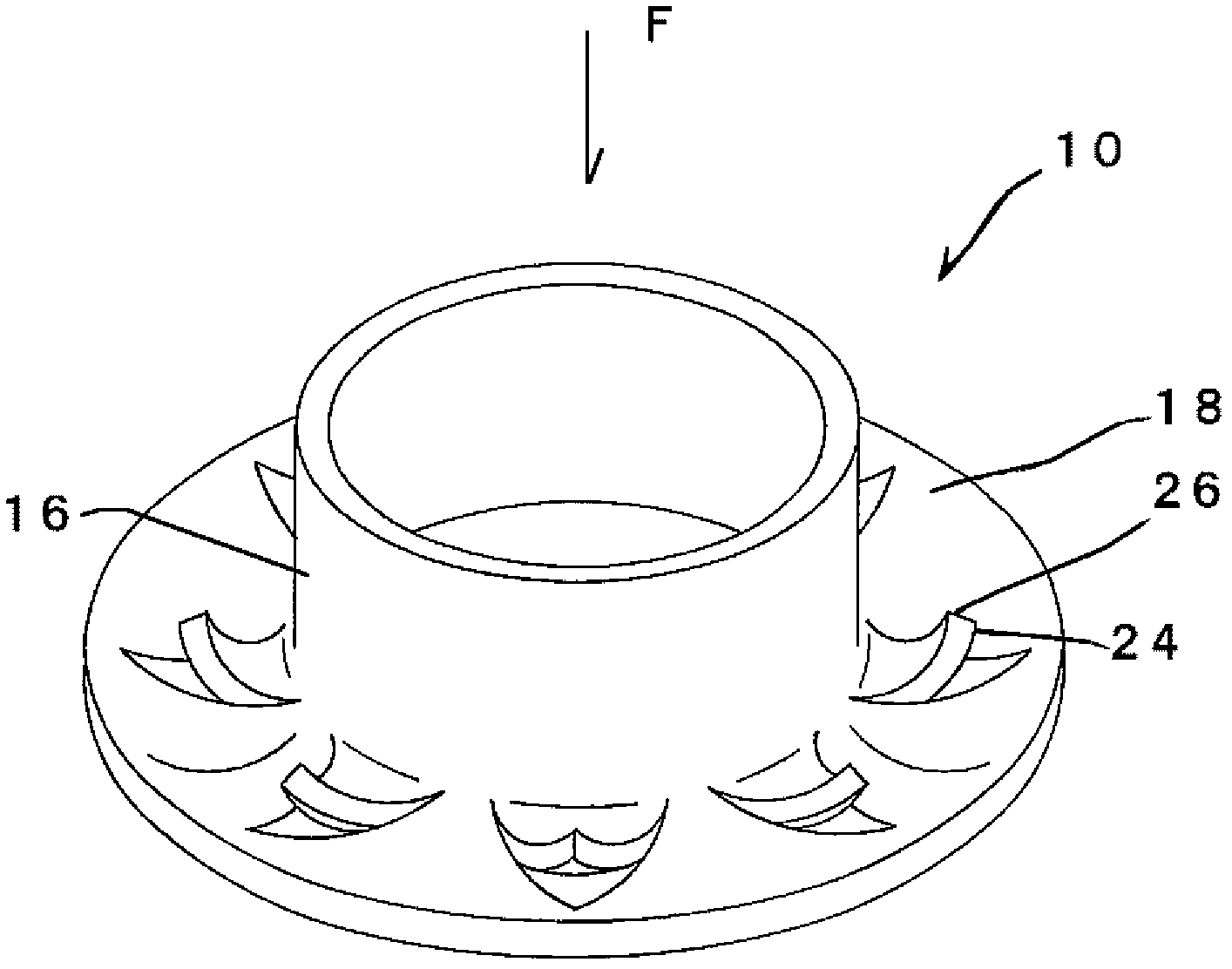

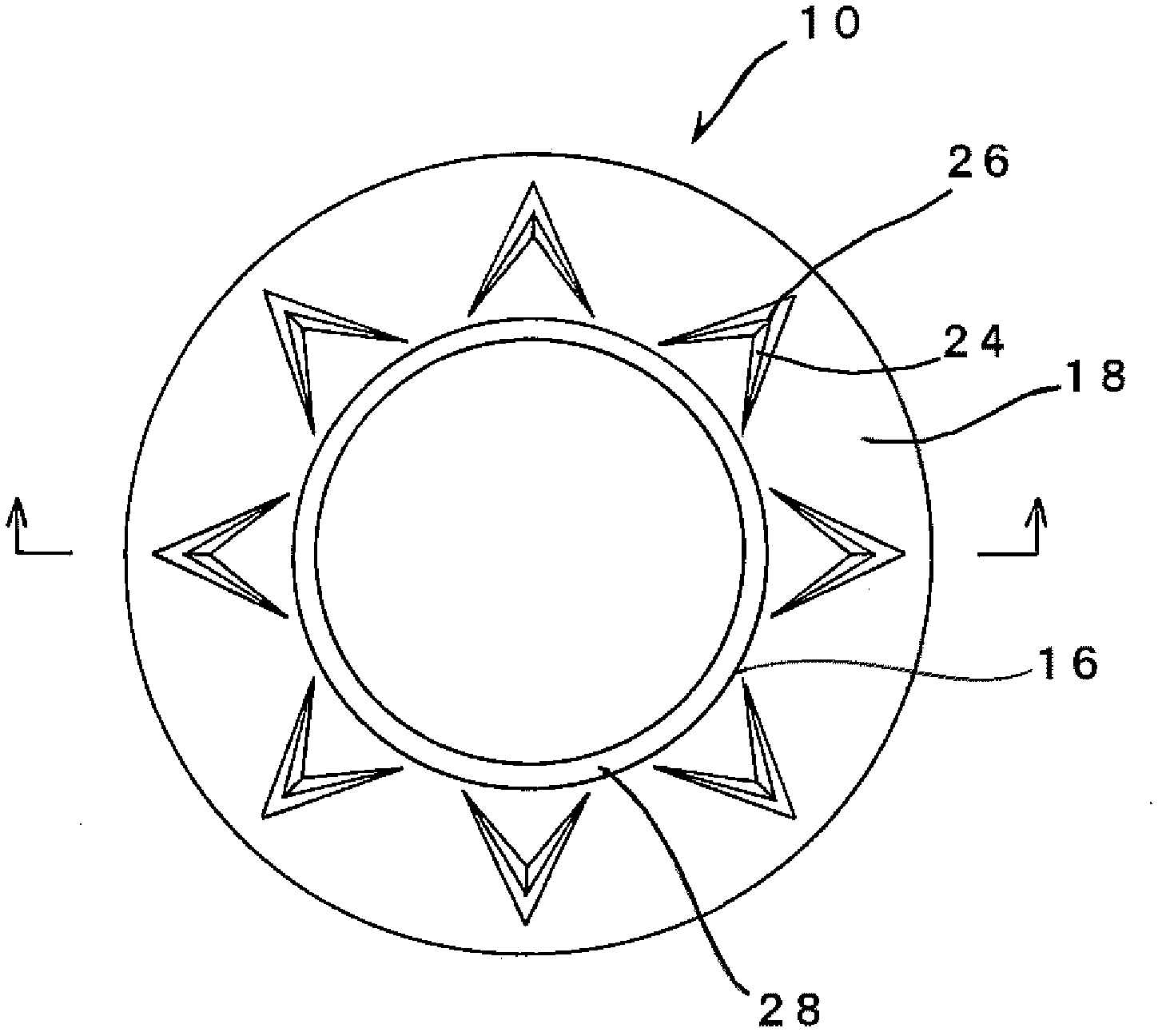

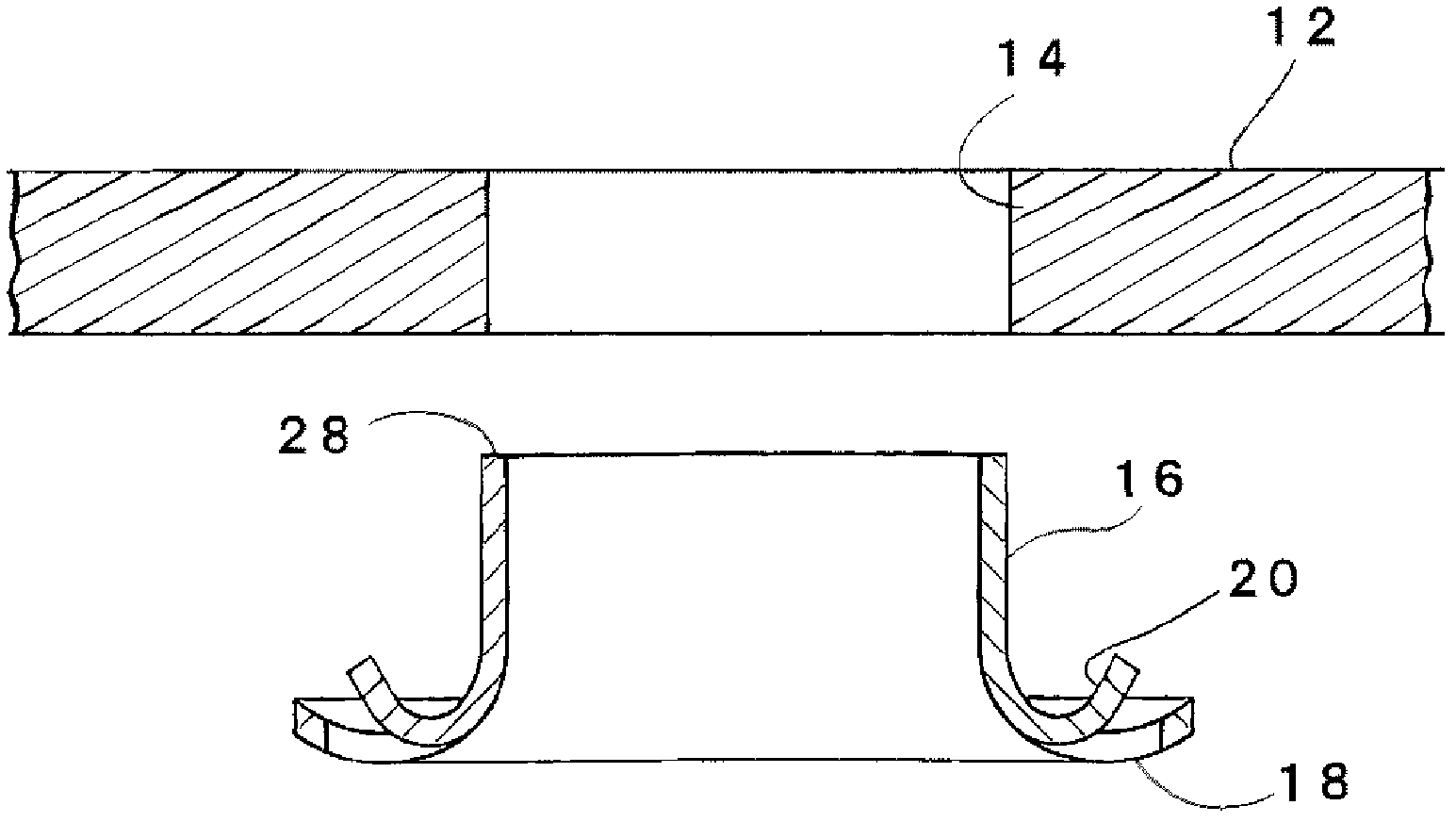

[0035] figure 1 It is a perspective view showing the eyelet 10 of the one-piece eyelet of the present invention before the riveting process. The eyelet 10 is made of representative metals such as brass, iron, nickel, aluminum, etc., and the eyelet 10 has a hollow cylindrical column 16 and a flange 18, and the column 16 has a structure capable of being inserted into a penetratingly formed surface. Materials such as cloth, resin sheet, etc. 12 ( image 3 ) on the outer diameter of the mounting hole 14, the flange 18 is configured on the material portion around the mounting hole 14, in image 3 In the embodiment, the flange 18 extends radially outward from the lower end of the column 16 in a state continuous with the column 16 .

[0036] After making the column 16 pass through the mounting hole 14, it becomes as riveted as Figure 4 and Figure 5 W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com