Rib components, side forms and molds for concrete tower components

A reinforcement and concrete technology, which is applied in molds, mold auxiliary parts, manufacturing tools, etc., can solve the problems of high manufacturing cost of prefabricated concrete tower components, reinforcement ribs cannot be reused, mold materials and labor waste, etc., to achieve easy Effects of implementation, reduction of design and installation burden, and improvement of mold accuracy and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

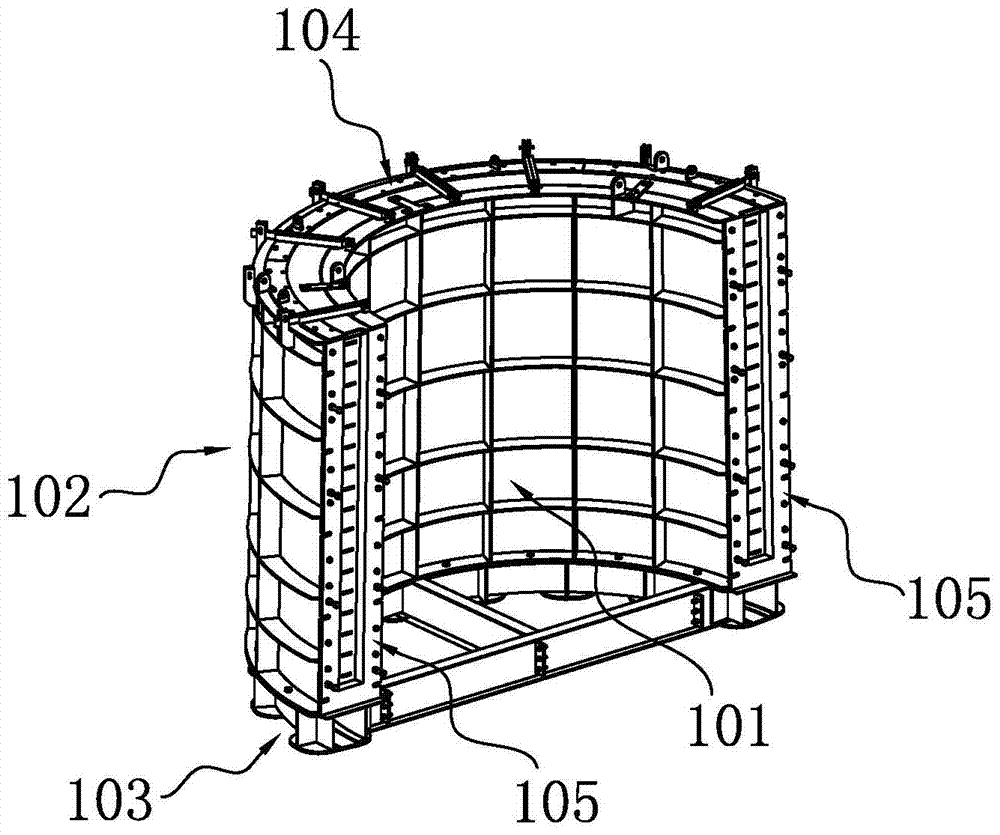

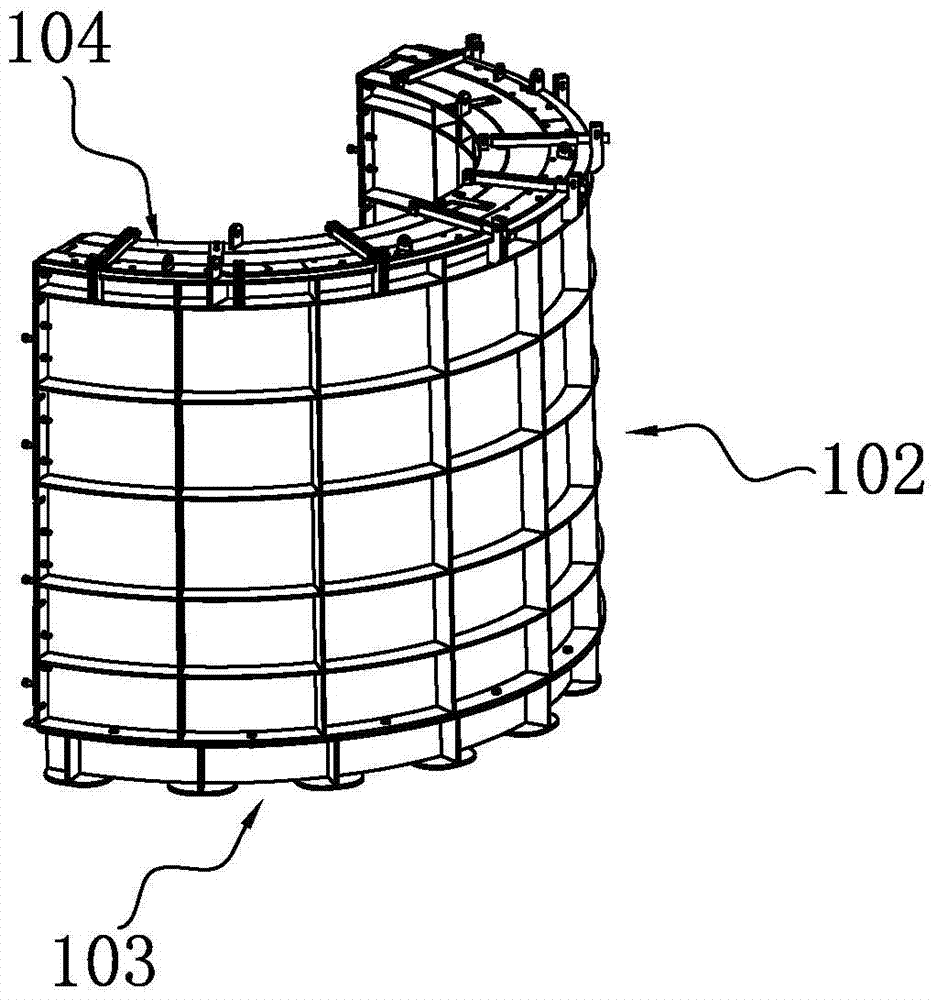

[0038] Such as Figure 5 to Figure 8 As shown, it is a drawing of the outer formwork of the concrete tower member in Embodiment 1 of the present invention, in addition to showing the reinforcing rib assembly, the formwork is also shown in the figure. Here, the rib assembly will be described first.

[0039] The reinforcing rib assembly in this embodiment includes a plurality of longitudinal reinforcing ribs 2 for detachably connecting to the template 1 , and a plurality of transverse reinforcing ribs 3 are connected to the longitudinal reinforcing ribs 2 through hinge bolts 4 .

[0040] In the rib assembly in this embodiment, its longitudinal rib 2 and transverse rib 3 are detachable, and the longitudinal rib 2 and the transverse rib 3 are connected by hinge bolts 4, so that the longitudinal rib 2 and the transverse The reinforcing rib 3 not only has detachability, but also the fixed position of the longitudinal reinforcing rib 2 on the transverse reinforcing rib 3 has certain...

Embodiment 2

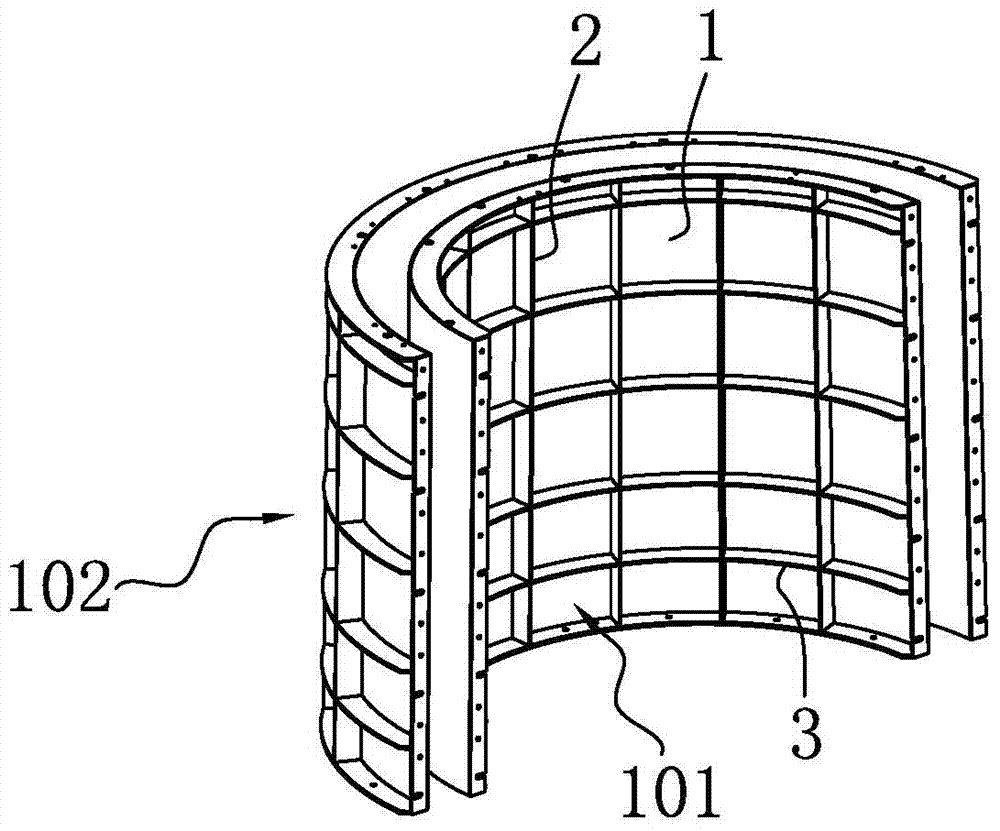

[0066] Such as Figure 9 to Figure 12 As shown, it is the accompanying drawing of the outer formwork of the concrete tower member of the second embodiment of the present invention. The difference between this embodiment and the previous embodiment mainly lies in the connection mode between the longitudinal rib 2 and the top and bottom of the formwork 1 different. In this embodiment, there is no top plate and bottom plate in Embodiment 1. In order to connect the longitudinal reinforcement 2 to the top and bottom of the template 1, in this embodiment, the two ends of the longitudinal reinforcement 2 are respectively connected by fastening bolts 8. The top connector 91 and the bottom connector 92 are provided with connection grooves (not marked in the figure) on the top connector 91 and the bottom connector 92, and the top edge and the bottom edge of the formwork 1 are located at the top connector 91 and the bottom respectively. In the connecting groove of the connecting piece 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com