Combined heat radiation oil pipe

A combined, oil-pipe technology, applied in pipeline heating/cooling, pipe/pipe joint/pipe fittings, fluid pressure actuation system components, etc., can solve problems such as slow heat dissipation in the oil circuit, rising oil temperature, and small heat dissipation area in the oil circuit , to achieve the effect of improving the heat exchange effect, increasing the contact area, and improving the heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

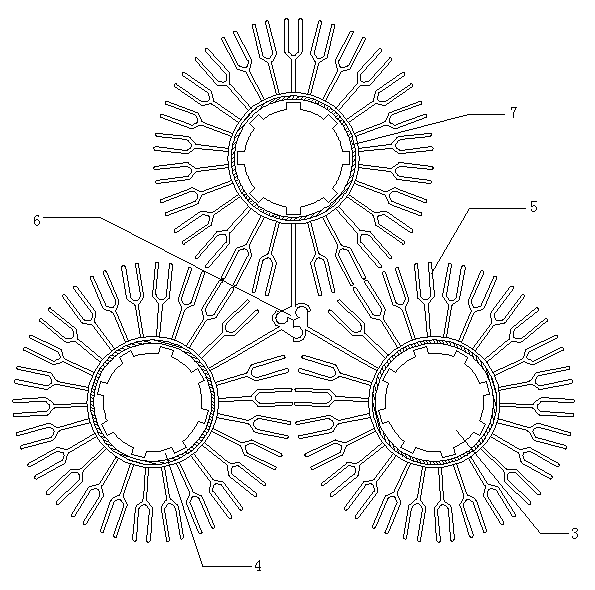

[0020] Such as figure 1 Shown is a schematic diagram of the structure of the present invention, the present invention is a combined heat dissipation oil pipe, which is spliced by heat dissipation oil pipes, and the two ends of the heat dissipation oil pipe are respectively converged into oil pipe inlet 1 and oil pipe outlet 2; oil pipe inlet 1 and oil pipe outlet 2 A fixed piece 8 is connected at the place; the fixed piece 8 is provided with a fixing hole 9 .

[0021] Such as figure 2 As shown, the number of heat-dissipating oil pipes is three; the heat-dissipating oil pipes are hollow cylinders, respectively including oil pipe layer 3 and heat dissipation la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com