Hydraulic energy-saving control system of cable reeling and unreeling vehicle

An energy-saving control system and cable reel technology, which is applied to fluid pressure actuating system components, fluid pressure actuating devices, servo motors, etc., can solve problems such as easy damage to hydraulic components, easy heat generation of hydraulic systems, and large energy loss. Achieve the effect of preventing cable damage, avoiding flow waste, and alleviating hydraulic shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

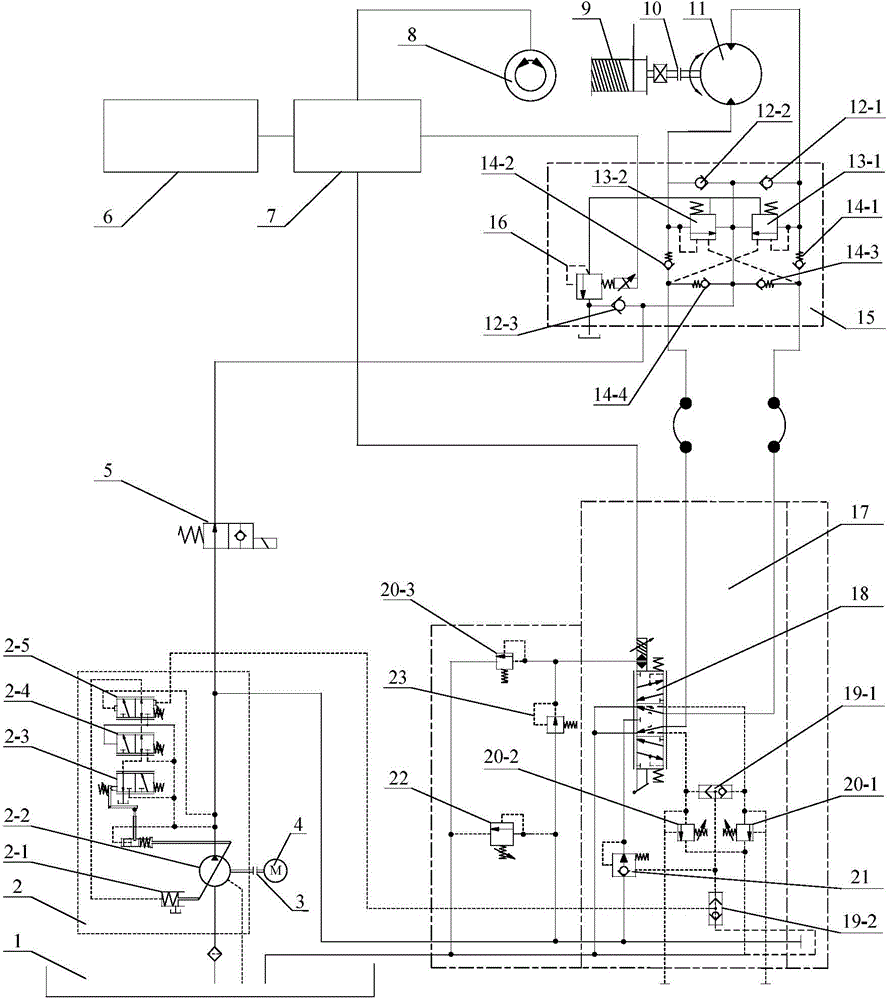

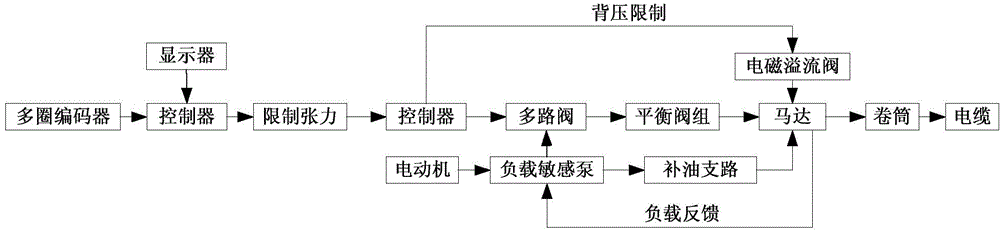

[0024] The present invention will be further described below in conjunction with accompanying drawing:

[0025] Such as figure 1 In the simplified structural diagram of the present invention shown, the control system of the present invention includes a fuel tank 1, a load sensing system 2, a coupling A3, a coupling B10, a motor 4, an oil replenishment switching valve 5, and a touch input function Display 6, controller 7, multi-turn encoder 8, reel 9, motor 11, balance valve assembly 15 and multi-way valve assembly 17; the motor 4 is connected to the load sensing system 2 through a coupling A; the load sensing system 2. Connect with multi-way valve assembly 17 through hydraulic oil pipe; multi-way valve assembly 17 and balance valve assembly 15 through hydraulic oil pipe; balance valve assembly 15 and motor 11 through hydraulic oil pipe; motor 11 and reel 9 through coupling B connection; the controller 7 is respectively connected to the multi-turn encoder 8, the display 6 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com